Safe window frame structure capable of facilitating internal mounting of glass and provided with integrated window screen, and casement window

A safety type, window frame technology, applied in the direction of window/door frame, leaf frame, leaf leaf layout, etc., can solve the problems of operation risk, poor product safety, installation risk, etc., to improve practicability and convenience , Stable and convenient Adaptive installation, stable and reliable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

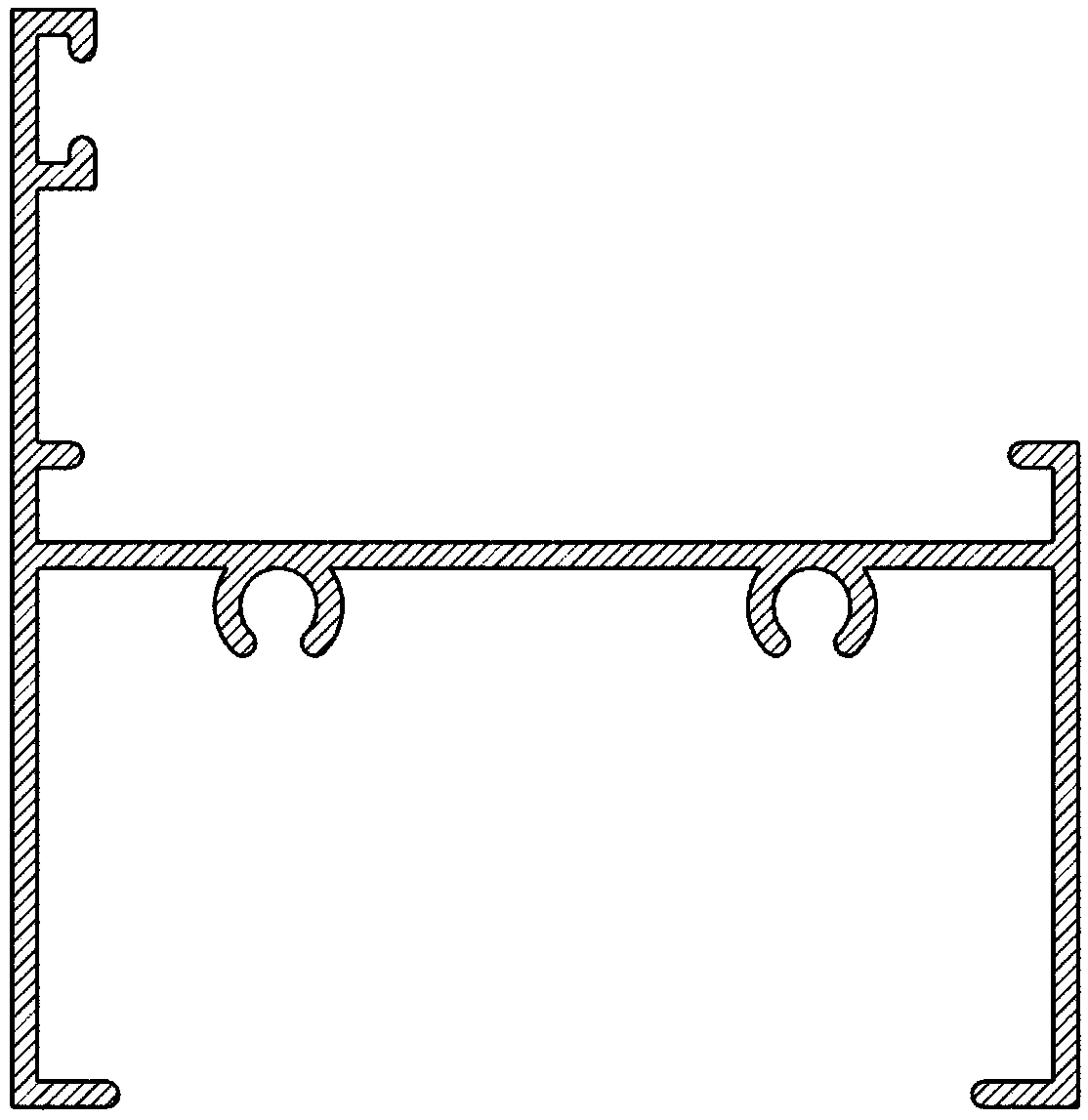

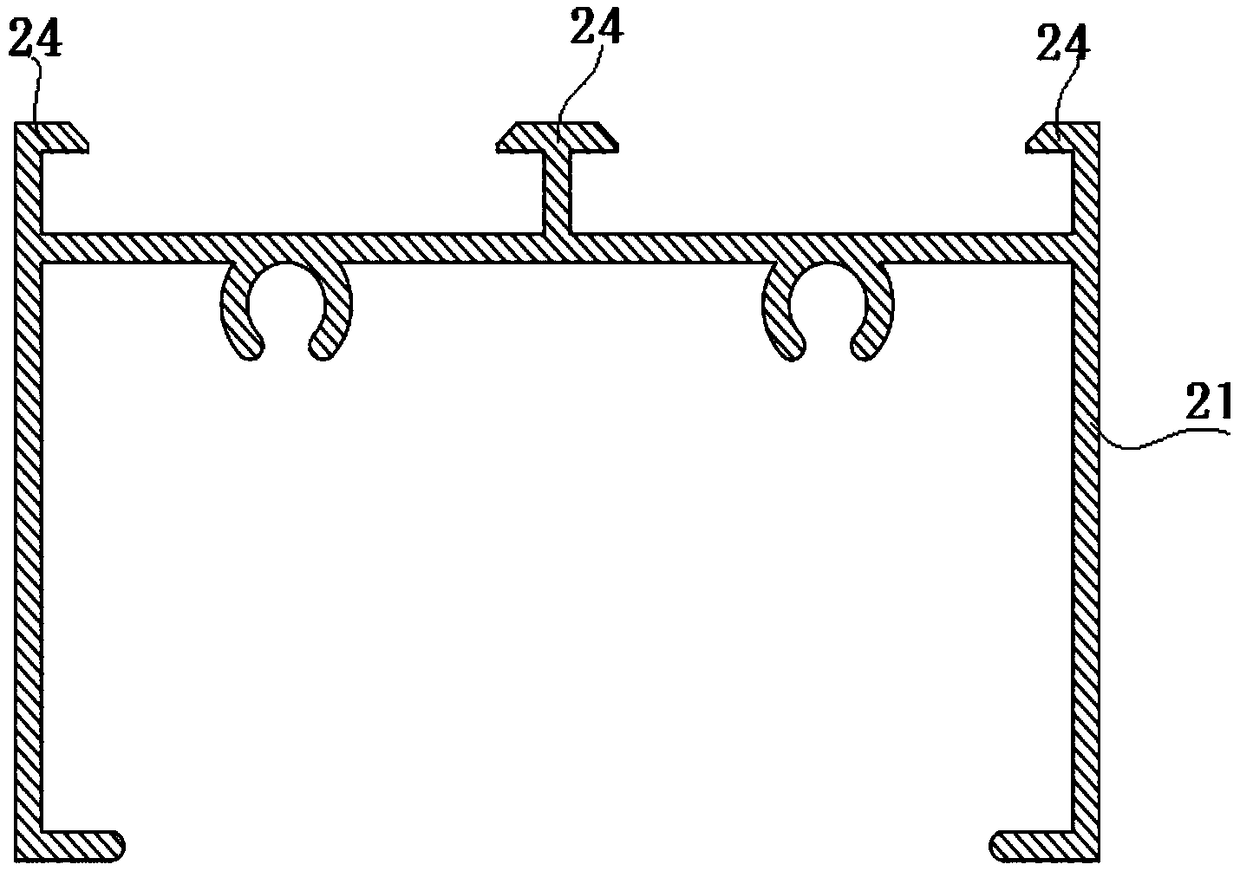

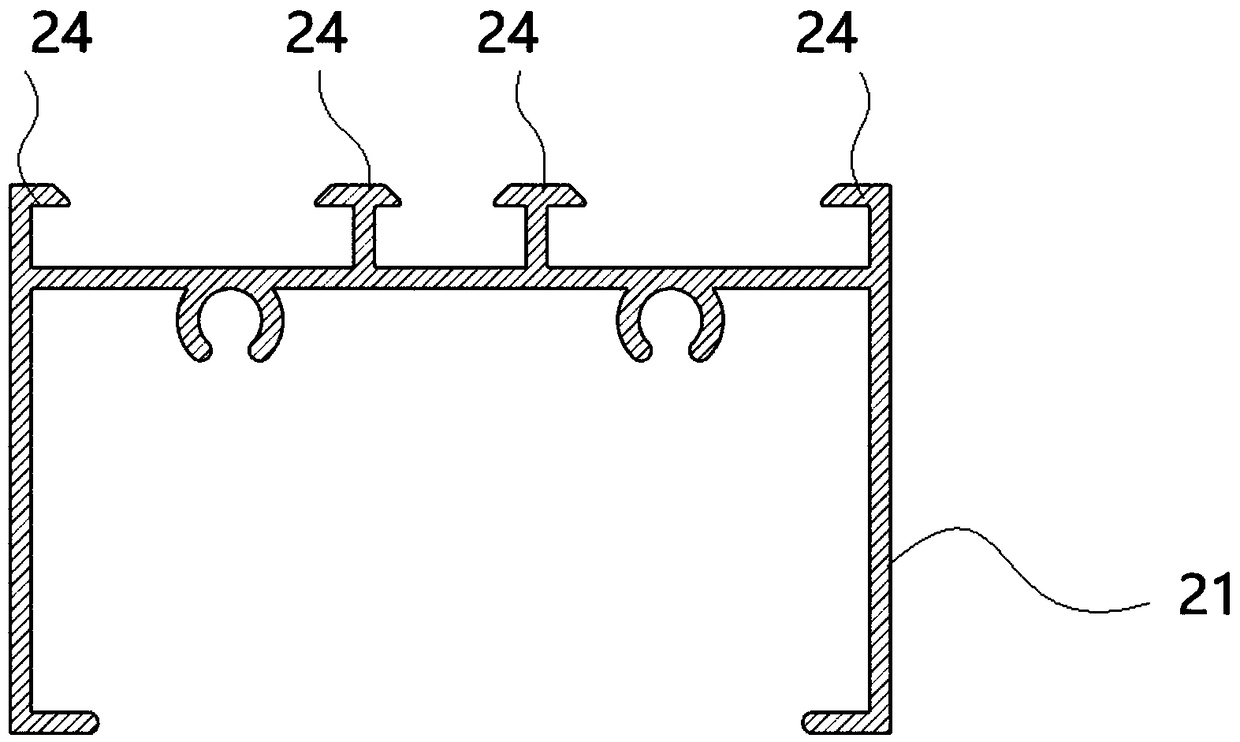

[0041] Embodiment 1: as Figure 11 As shown, the safety window frame structure that is easy to be installed in the glass and integrated with the screen window includes: a rectangular window frame 2 for installing the window sash 1 composed of a bottom frame 21, a top frame 22 and two frames 23, the bottom The upper surface of the frame 21 and the lower surface of the top frame 22 respectively have four fixed clamping strips 24 extending along the surface and protruding upwards and downwards respectively, and the movable brackets that are matched with the fixed clamping strips 24 and snap-fitted The bar 3 is installed on the upper surface of the bottom frame 21 and the lower surface of the top frame 22, the movable bar 3 includes an upright baffle part 31, and the baffle part 31 is located on the bottom frame 21, the middle part of the lower surface of the top frame 22. In the actual installation process, taking the bottom frame 21 as an example, since the fixed clip 24 can be...

Embodiment 2

[0047] Example 2, such as Figure 14 ~ Figure 15As shown, on the basis of Embodiment 1, the inner side of the frame 23 of the window frame 2 close to the side of the window sash 1 as the opening and closing rotation axis and the outer side of the vertical edge 13 of the window sash 1 opposite to it are installed with connected Anti-drop chain 4. The anti-drop chain 4 includes a metal rope 41 and two anti-drop sliders 42 sleeved in the metal rope 41, wherein one anti-drop slider 42 is fixed on one end of the metal rope 41, and the other anti-drop slider 42 It can slide on the metal rope 41 but cannot slide out of the end of the metal rope 41; two mortises 43 are provided on both sides of the anti-falling slider 42, and the window frame 2 is opened close to the window sash 1. On the inner side of the frame 23 on the side of the closed rotation axis and on the outer side of the vertical edge 13 of the window sash 1 opposite to it, there are slide grooves 44 matching the tenons 4...

Embodiment 3

[0048] Example 3, such as Figure 16 As shown, a casement window assembled using the window frame profiles described in Embodiment 1 or 2, such a casement window also includes a screen fan 51 that is movably installed in the window frame 2, and the screen fan 51 includes The upper yarn material 52 and the lower yarn material 53, the upper yarn material 52 and the lower yarn material 53 are respectively connected to the respective side walls and baffle parts of the top frame 22 and the bottom frame 21 when the screen window 5 is installed. The space formed between 31 is suitable and embedded movable installation. In the same way, just because the baffle part 31 is arranged in the middle of the window frame 2, a space formed by a gap between the left and right sides of the baffle part 31 and the edge of the window frame 2 on the respective side is reserved, The space on one side is used to install the window sash 1, and the space on the other side is used to install the screen ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap