Double check diaphragm check valve

A check valve, diaphragm technology, applied in the direction of lift valve, valve details, control valve, etc., can solve the problem of oil return phenomenon, small contact area, etc., to achieve good check effect, increase contact area, and easy to clean. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

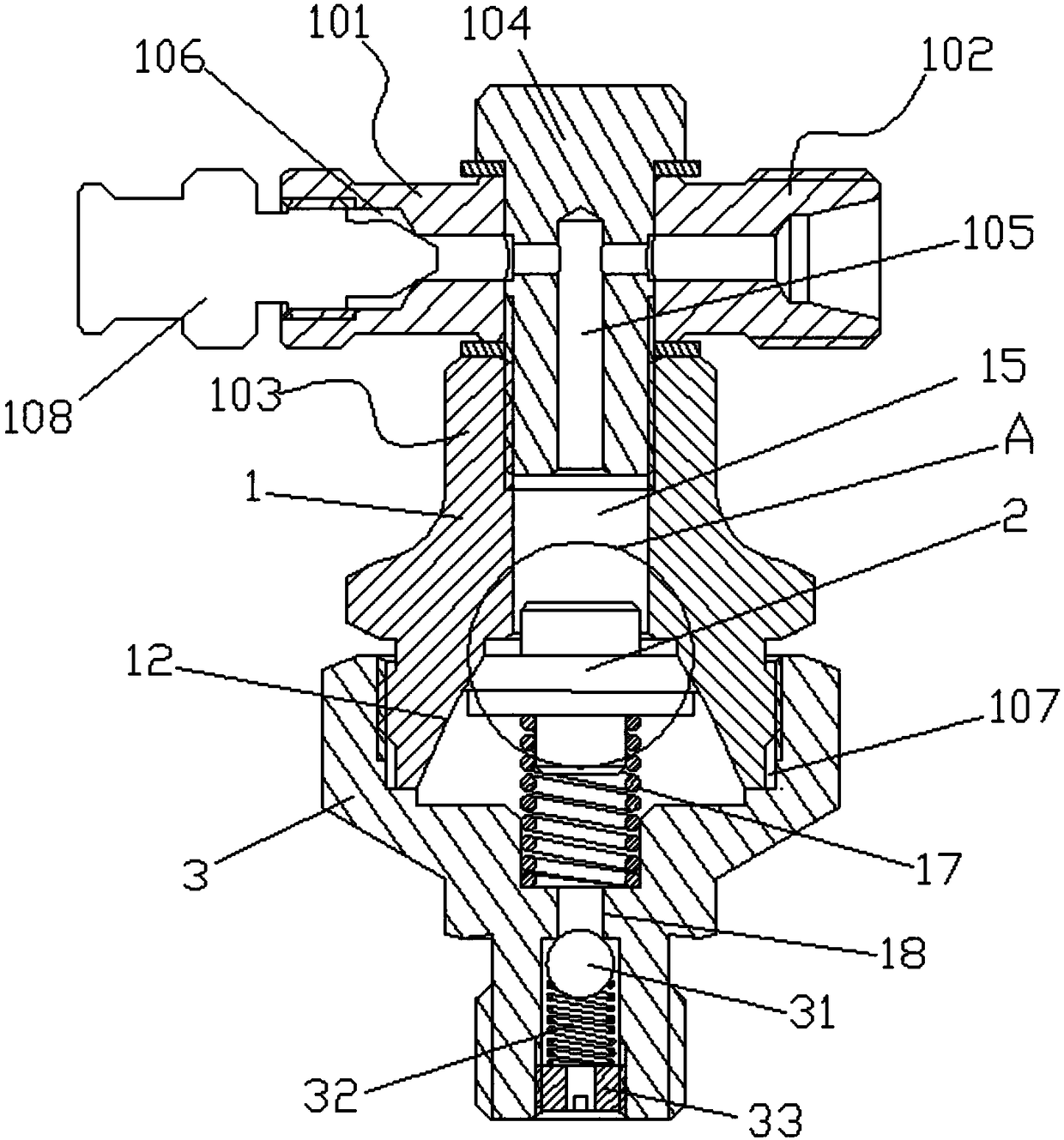

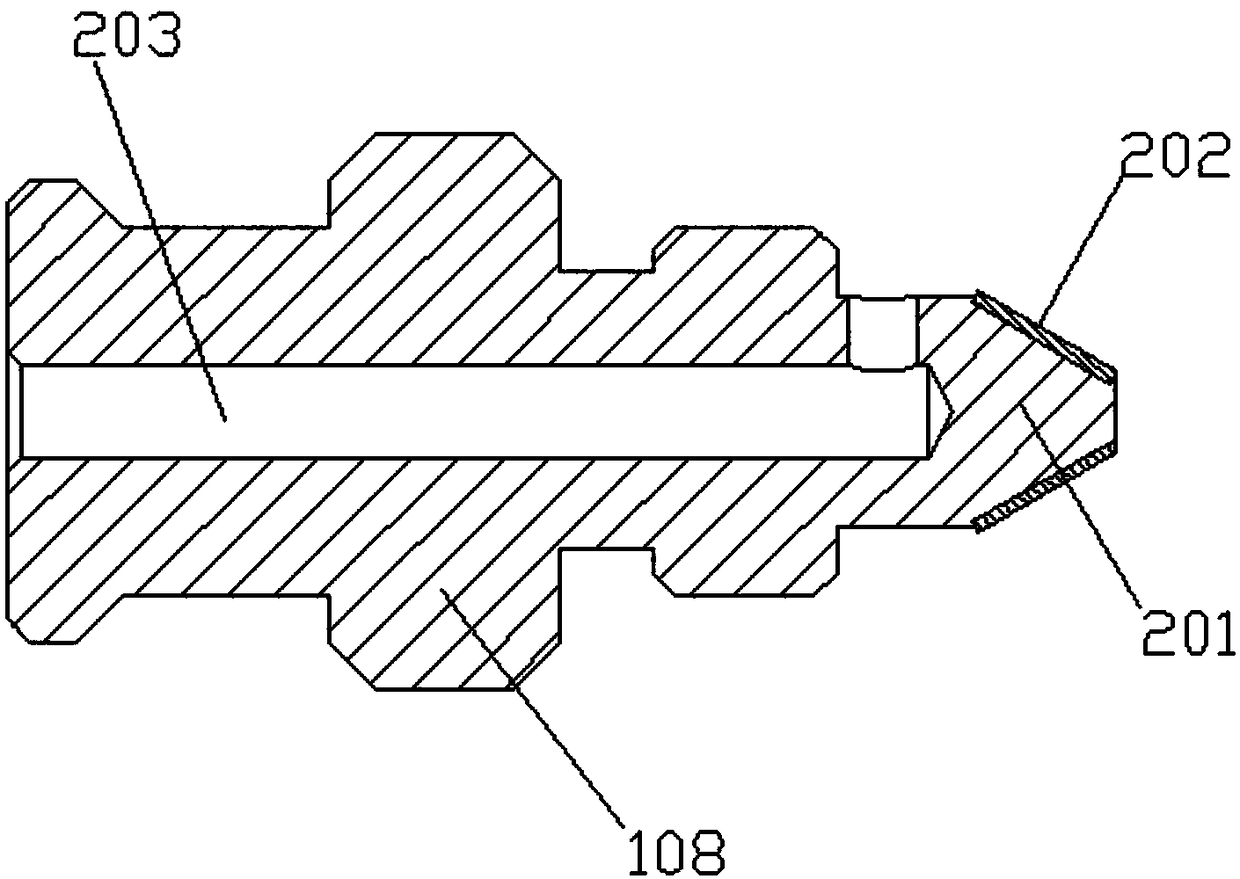

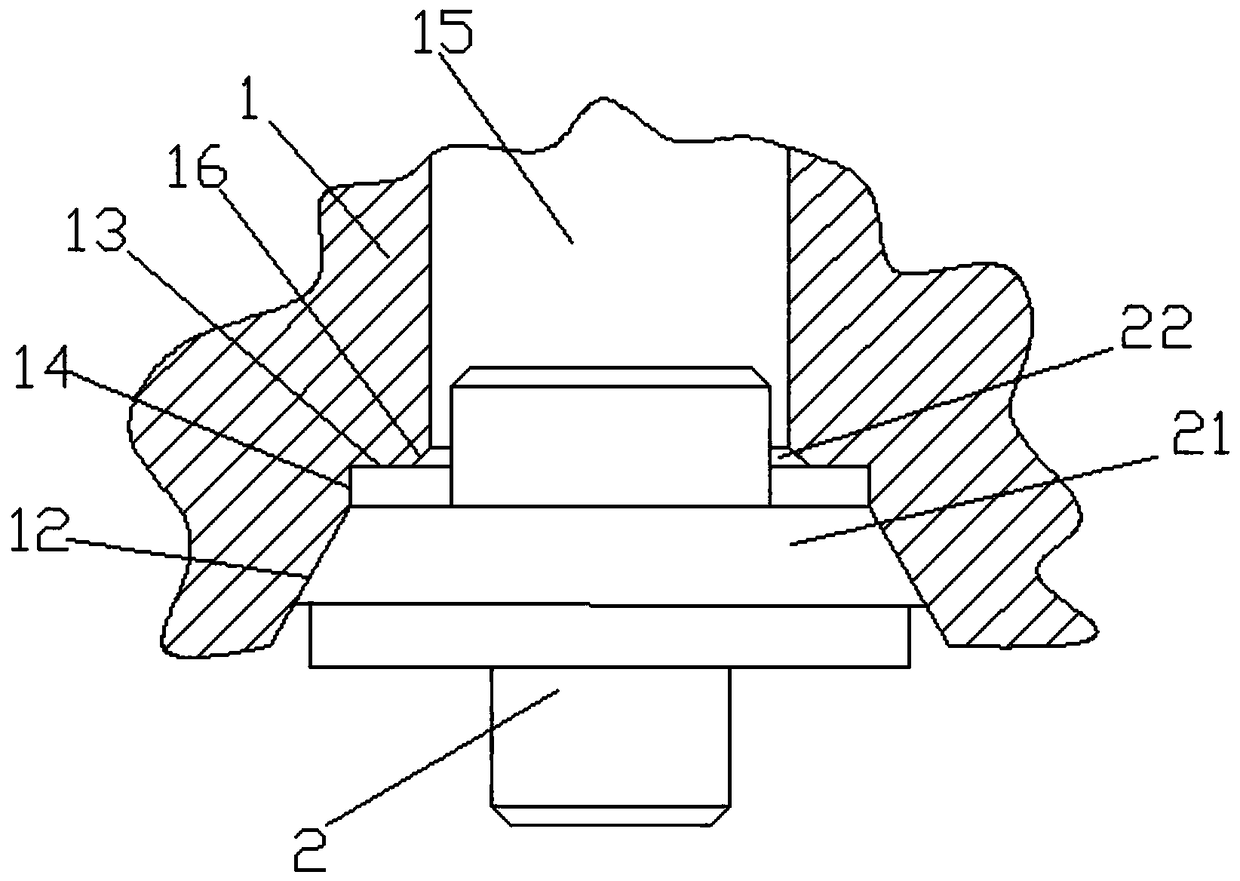

[0028] exist figure 1 on the basis of image 3 Shown; a double check diaphragm check valve, including a valve body 1 with a funnel-shaped mouth 12 inside the lower end, a diaphragm assembly 2 installed inside the mouth 12, and a valve body installed at the lower end of the valve body 1 The lower end cover 3, the central axis of the bucket mouth 12 coincides with the central axis of the valve body 1, the bottom of the bucket mouth 12 is provided with a stepped surface 13, the stepped surface 13 is perpendicular to the central axis of the valve body 1, and the stepped surface 13 is connected to the side of the bucket mouth 12 A cylindrical surface 14 is arranged between them. The upper end structure of the diaphragm 21 of the diaphragm assembly 2 is a cylinder, and the lower end structure is a circular platform. The cylindrical structure part of the diaphragm 21 is located on the cylindrical surface 14, and the circular platform part of the diaphragm 21 is located in the bucket ...

Embodiment 2

[0036] exist figure 1 on the basis of image 3 Shown; a double check diaphragm check valve, including a valve body 1 with a funnel-shaped mouth 12 inside the lower end, a diaphragm assembly 2 installed inside the mouth 12, and a valve body installed at the lower end of the valve body 1 The lower end cover 3, the central axis of the bucket mouth 12 coincides with the central axis of the valve body 1, the bottom of the bucket mouth 12 is provided with a stepped surface 13, the stepped surface 13 is perpendicular to the central axis of the valve body 1, and the stepped surface 13 is connected to the side of the bucket mouth 12 A cylindrical surface 14 is arranged between them. The upper end structure of the diaphragm 21 of the diaphragm assembly 2 is a cylinder, and the lower end structure is a circular platform. The cylindrical structure part of the diaphragm 21 is located on the cylindrical surface 14, and the circular platform part of the diaphragm 21 is located in the bucket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com