Spiral feeding sifter for oil-tea camellia fruit

A technology of screw feeding and Camellia oleifera fruit, which is applied in the fields of sieving, solid separation, fat oil/fat production, etc., can solve the problems of low shelling rate, resource consumption, and low oil content in nut shells, so as to improve the shelling rate, The effect of improving shelling efficiency and reducing breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

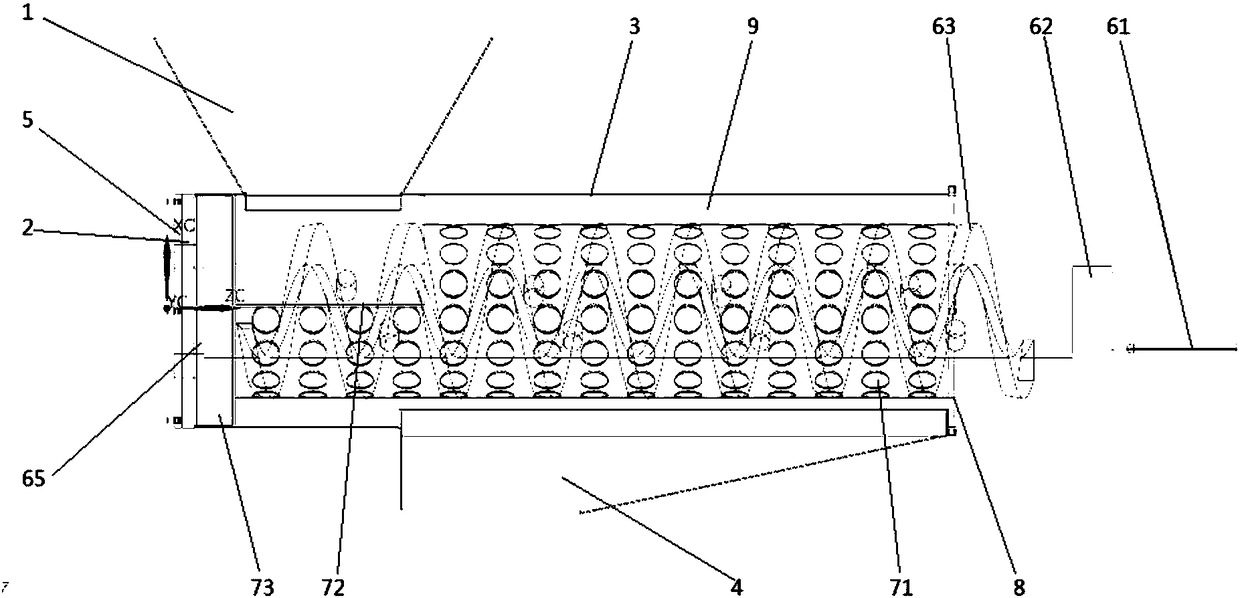

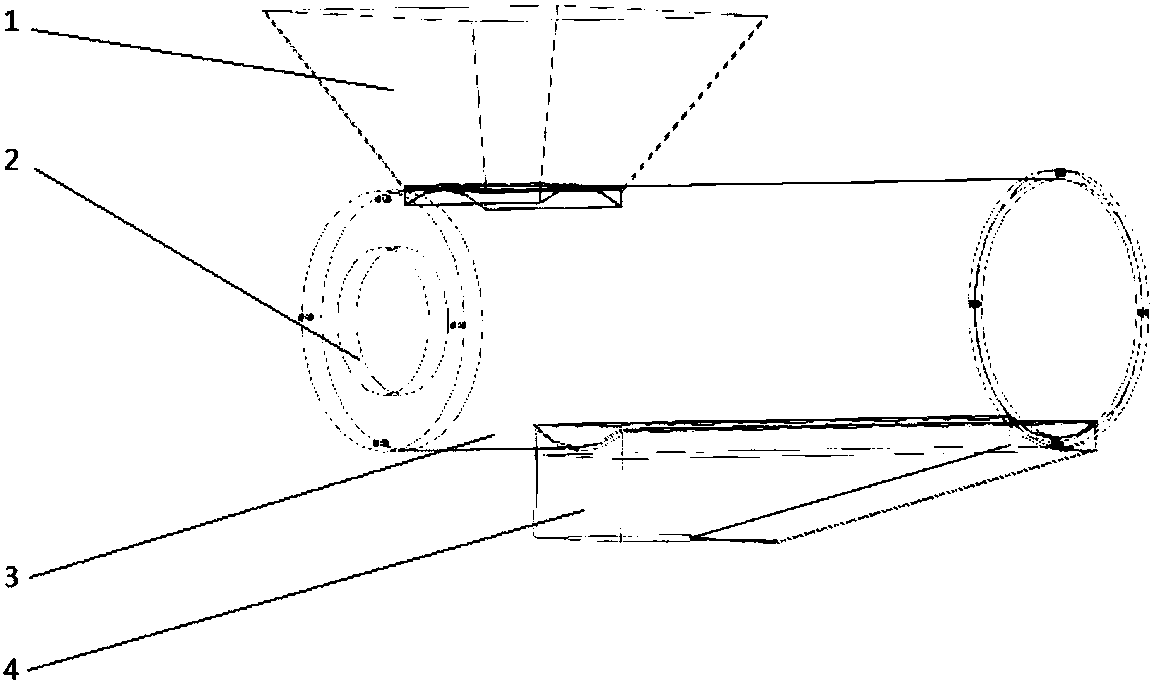

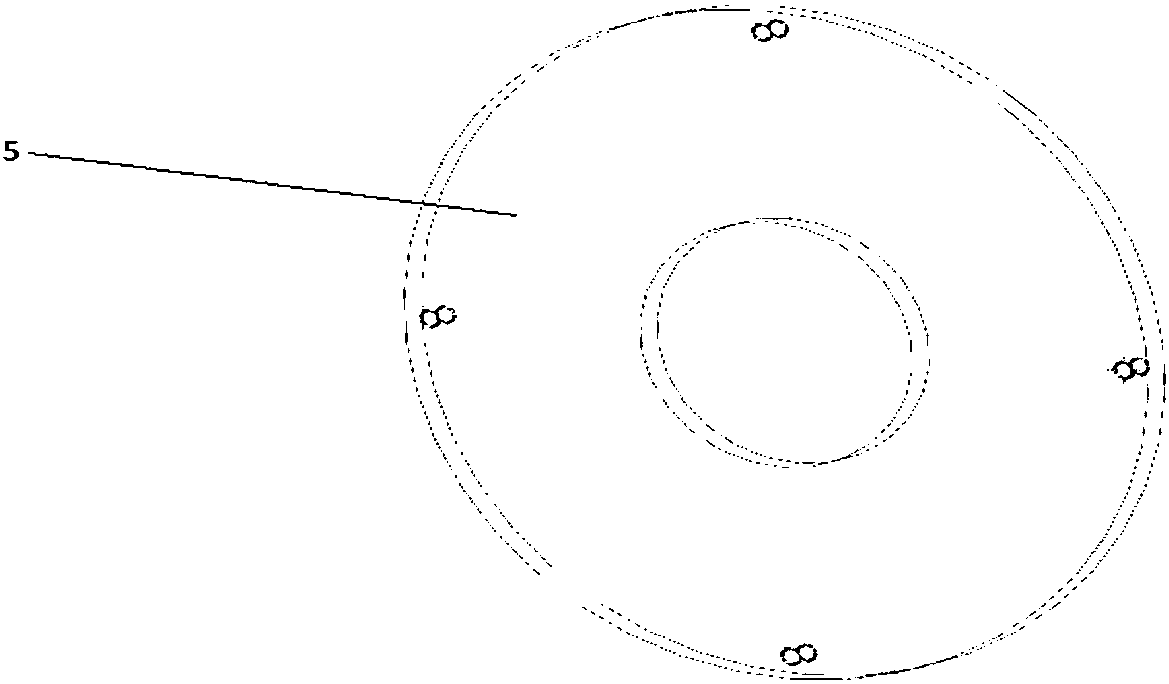

[0025] A kind of Camellia oleifera screw feeding sifter, such as figure 1 As shown, in the Camellia oleifera screw feeding sieve structure of the present invention, the feed hopper 1 is positioned above the casing 3 and is seamlessly connected to the casing 3, the discharge port 4 is positioned below the casing 3, and there is no The seam is connected to the shell 3, and one end of the shell 3 is provided with a bearing seat 2, and the cylindrical grooves 62 and 65 on the spiral stirring shaft 6 can be fixedly supported on the hulling machine frame and the bearing seat 2 respectively by installing bearings. The baffle plate 5 is fixed on the bearing seat 2 by bolts to ensure that the bearing is fixed. The front end of the screen 7 is provided with a screen cylinder 73. The scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com