Plastic profile cutting device

A technology of cutting equipment and plastic profiles, which is applied in metal processing and other directions, can solve problems such as low precision, poor safety, and low product quality, and achieve the effects of prolonging the life of the motor and reducing cutting errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

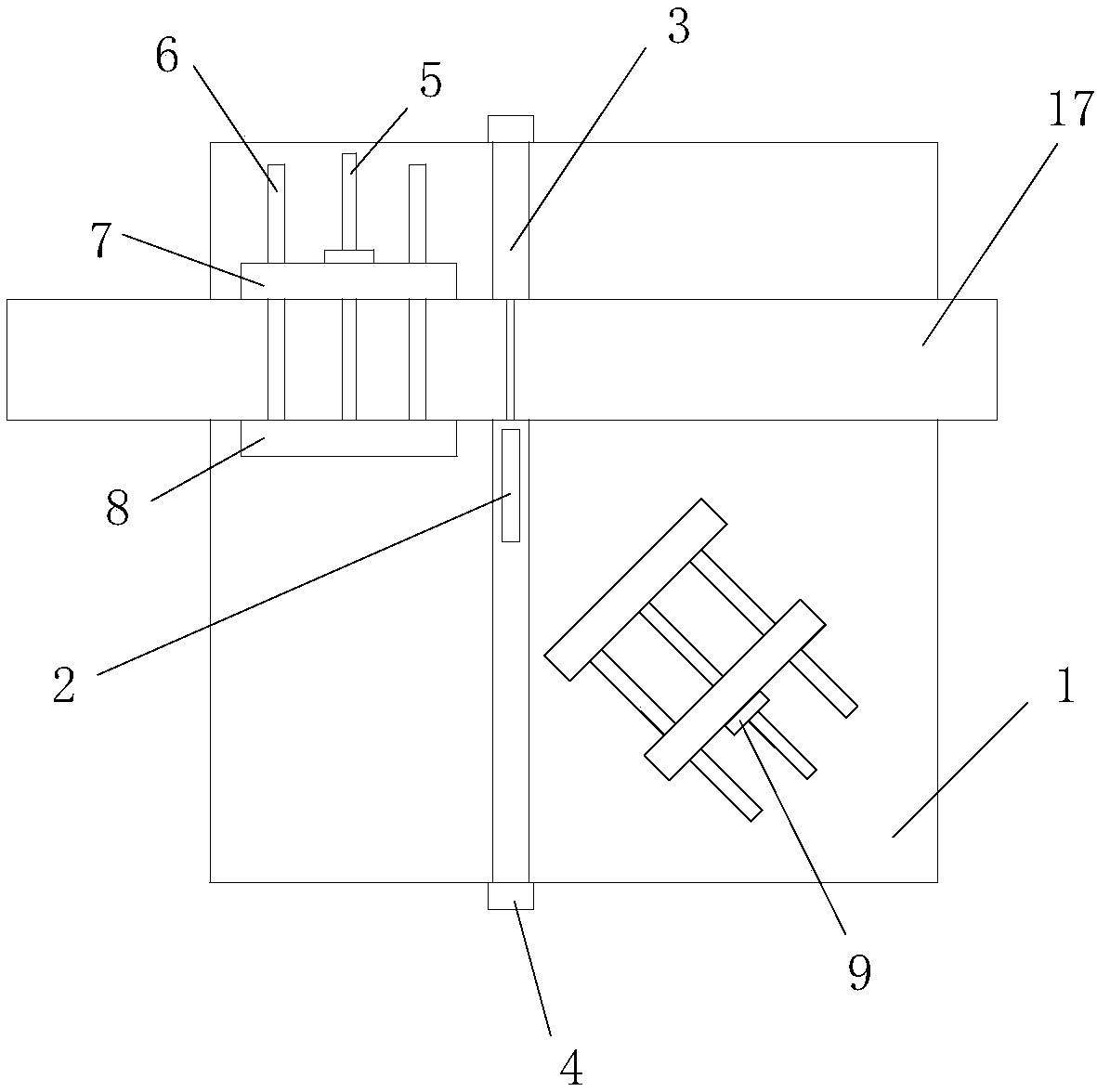

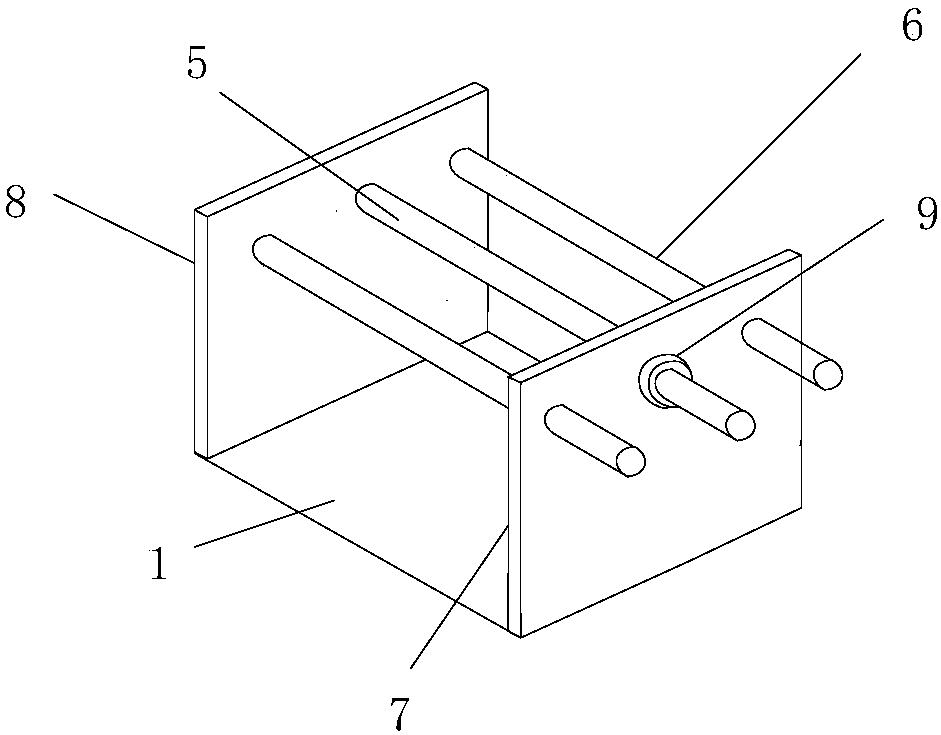

Embodiment 1

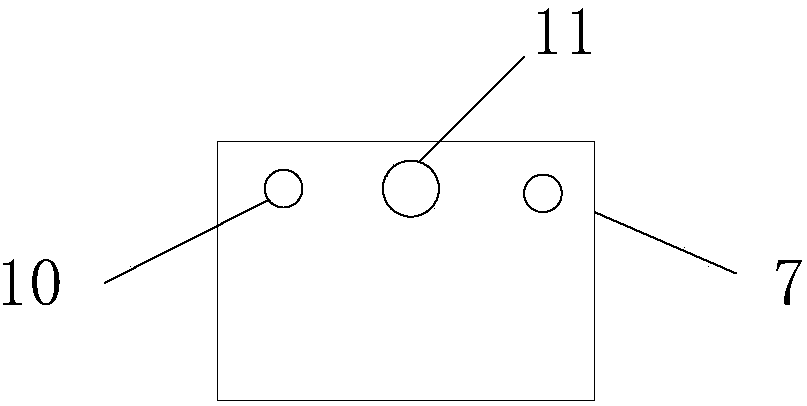

[0028] Among the two sets of clamping mechanisms, the group of threaded rods 5 parallel to the first rail 3 is suitable for cutting perpendicular to the direction of plastic profiles 17, and the group of threaded rods 5 and the first rail 3 at an angle of 45 degrees is suitable for profile Chamfer at both ends at 45 degrees.

[0029] When in use, select a suitable clamping mechanism according to processing requirements, and mark the cutting position on the plastic profile 17 . Rotate the adjustment wheel 9 to increase the distance between the sliding clamping part 7 and the fixed clamping part 8, then place the plastic profile 17 between the sliding clamping part 7 and the fixed clamping part 8, turn on the laser emitter, and push it back and forth For the plastic profile 17, when the light spot just falls on the marked cutting position, the adjusting wheel 9 is rotated in the opposite direction, so that the sliding clamping part 7 and the fixed clamping part 8 clamp the plast...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap