A kind of ship hull plugging device and its plugging method

A hull and airbag technology, which is applied to the safety of ships, transportation and packaging, ships, etc., can solve the problems of unfavorable fixing of auxiliary equipment, inability to achieve all-round plugging, and affecting the direction of navigation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0084] like Figure 12A to Figure 12B Shown is the second kind of hull leak plugging device, and the hull leak plugging device includes an umbrella body mechanism 30, and the umbrella body mechanism 30 includes an umbrella handle 31, an umbrella frame 32 and an umbrella bag 33, and the umbrella bag 33 covers The umbrella frame 32, the umbrella frame 32 is foldably connected to one end of the umbrella handle 31, and the other end of the umbrella handle 31 is equipped with a pair of holders 311 and an umbrella holder gas cylinder 313, the holder 311 The umbrella handle 31 is provided with an umbrella stand air passage 312, and the umbrella frame 32 is provided with a plurality of air holes 320, and the umbrella stand air passage 312 communicates with all the air passages through the air holes 320. The umbrella stand gas cylinder 313 and the umbrella bag 33 are used so that the umbrella bag 33 drives the umbrella frame 32 to fan out, so that the outer edge of the umbrella bag 33 ...

Embodiment 3

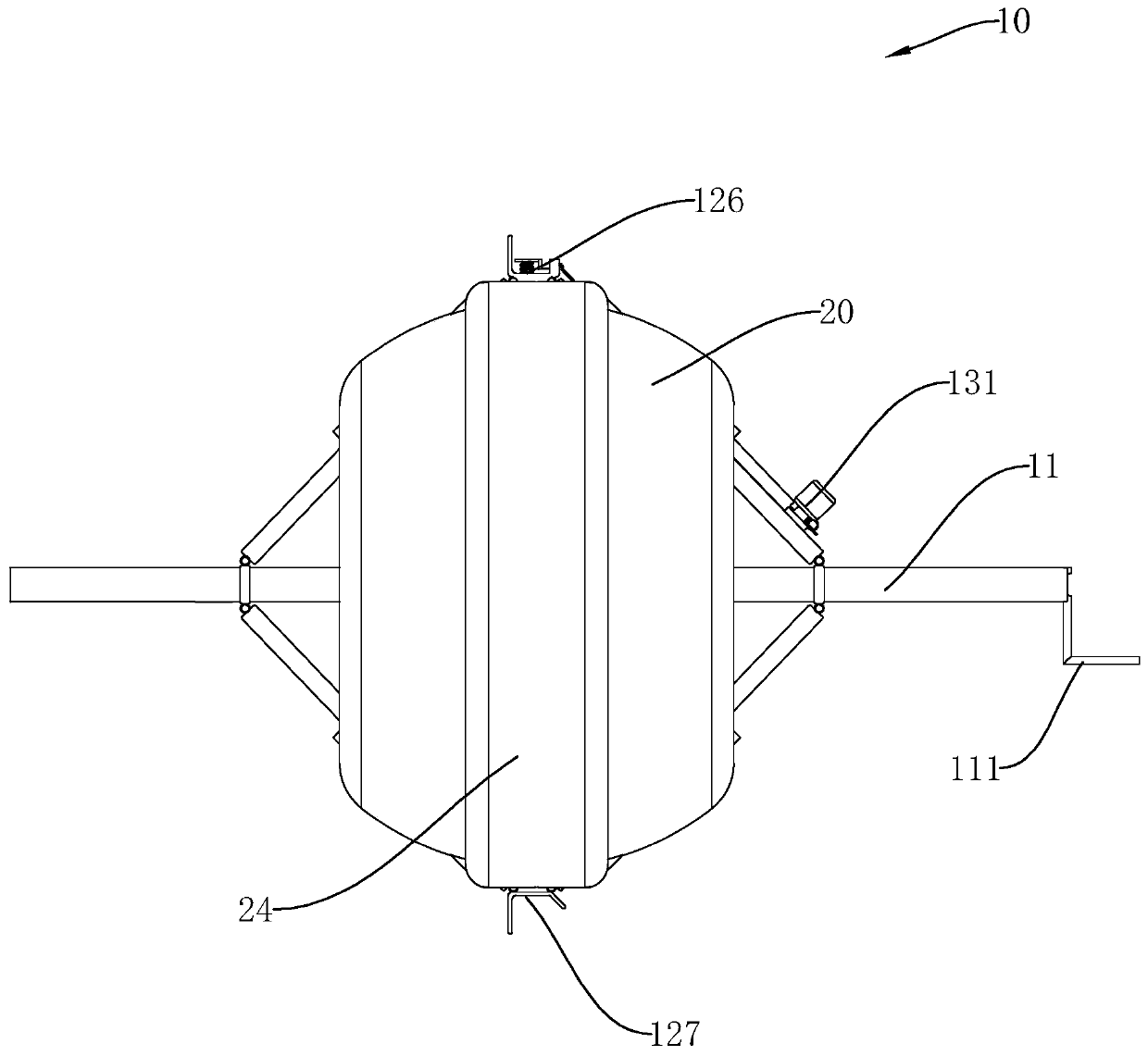

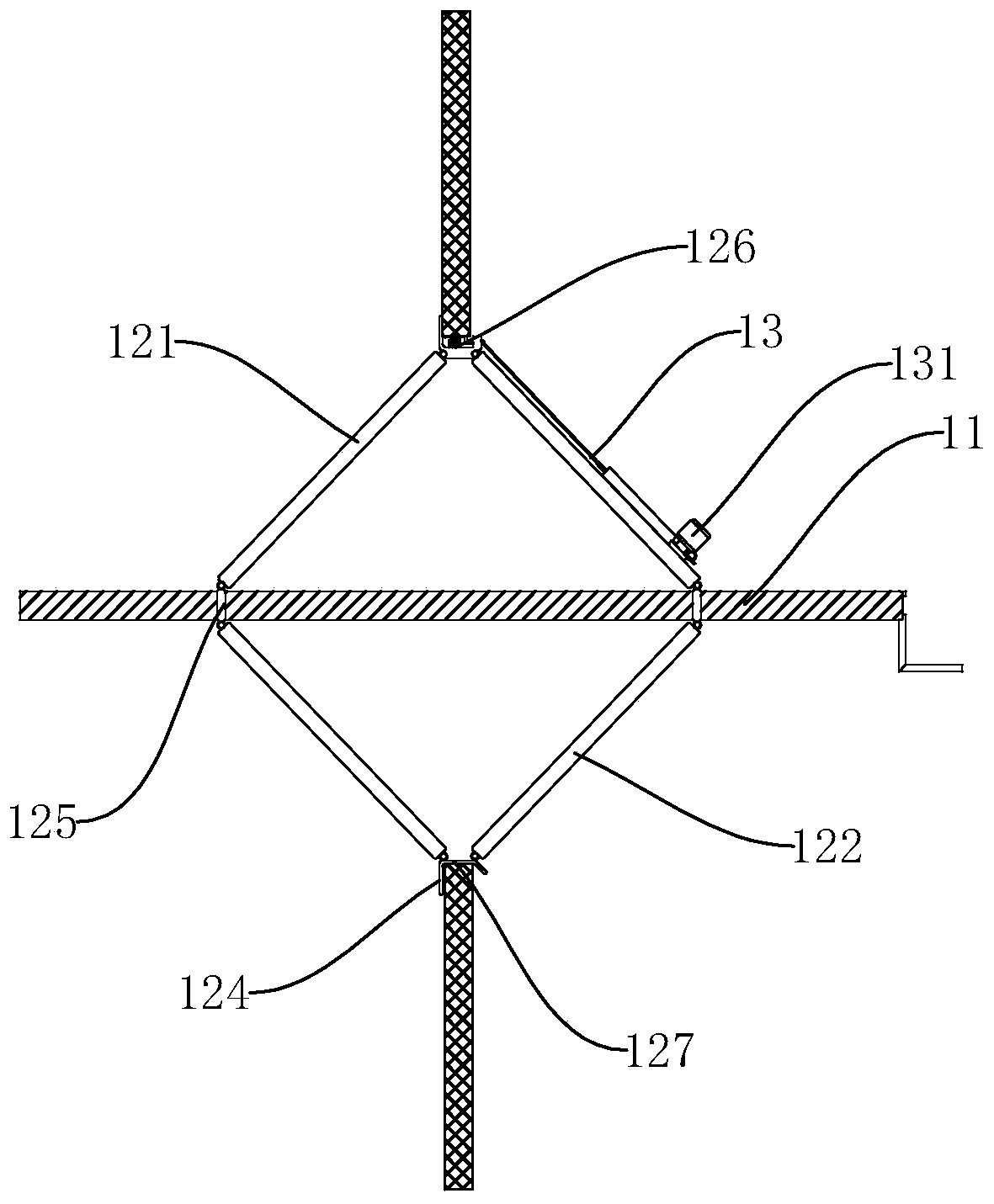

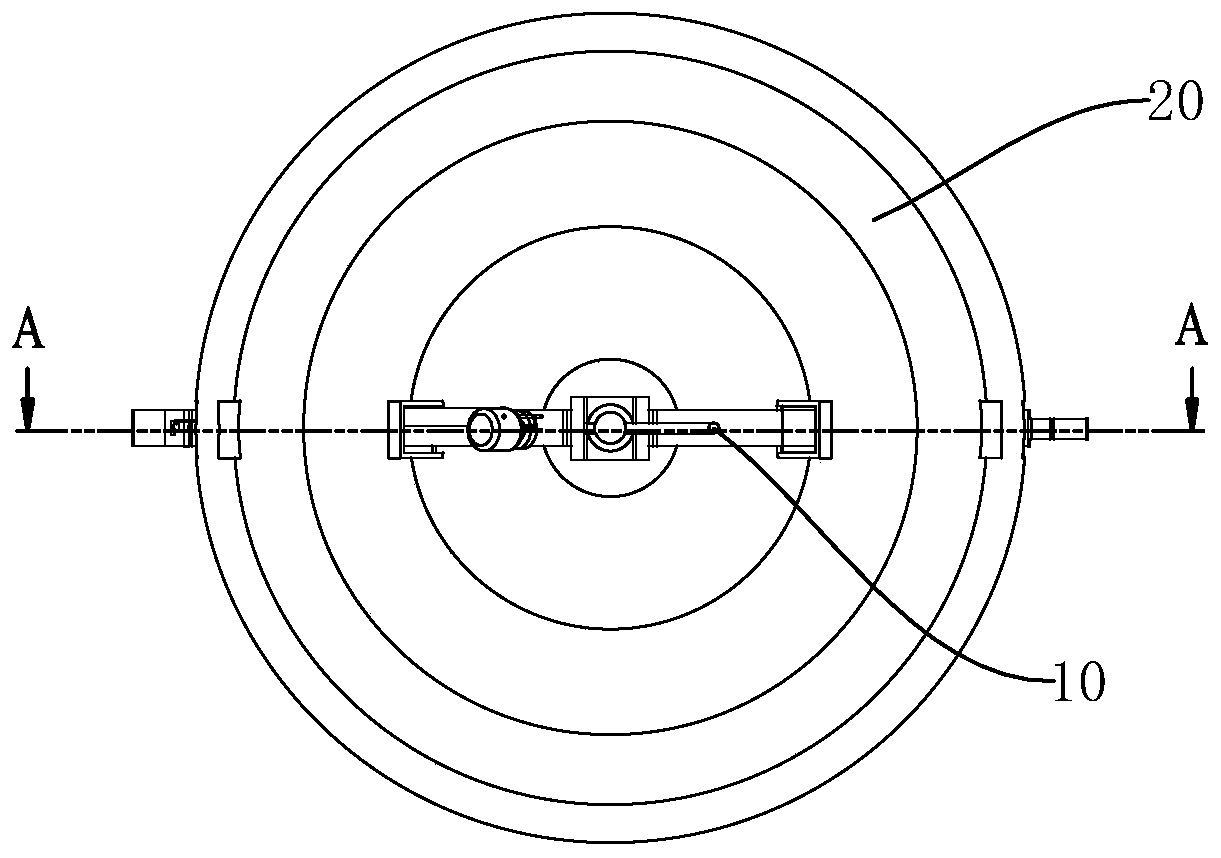

[0100] Figure 10 to Figure 12B Shown is the third hull plugging device, which includes a positioning mechanism 10, an air bag 20 and an umbrella body mechanism 30, the positioning mechanism 10 is sleeved in the air bag 20, and the air bag 20 can be Inflated and expanded, the umbrella body mechanism 30 is attached to the positioning mechanism 10, the positioning mechanism 10 is provided with a main shaft 11 and a telescopic member 12, and the telescopic member 12 is radially and telescopically connected to the main shaft 11, so The umbrella mechanism 30 is provided with an umbrella handle 31, an umbrella frame 32 and an umbrella bag 33, the umbrella bag 33 covers the umbrella frame 32, and the umbrella frame 32 is foldably connected to the front end of the umbrella handle 31, The umbrella handle 31 runs through the main shaft 11 of the positioning mechanism 10, the umbrella frame 32 can support the umbrella bag 33 to be attached to the outer wall of the hull, the positioning m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com