A kind of non-curing rubber asphalt waterproof coating for wet ground and preparation method thereof

A technology of asphalt waterproof coating and non-curing rubber, which is applied in the direction of asphalt coating, anti-corrosion coating, fire-proof coating, etc. It can solve the problems of insufficient paving, detachment from the base layer, and insufficient viscosity, etc., and achieve good waterproof performance, excellent self-healing performance, and shortened construction time cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A non-curing rubber asphalt waterproof coating for wet ground, consisting of component I and component II:

[0040] The component I (non-curing component) is made of the following raw materials in weight percentage: 37% of high-grade asphalt, 12% of softened oil, 13% of aromatic oil, 8% of modifier, 1.5% of extension agent, rubber powder 10%, petroleum resin 8%, filler 10%, anti-aging agent 0.5%;

[0041]The component II (wet interface material) is made of the following raw materials in weight percentage: 50% ethyl acetate, 40% rosin resin, 3% titanate coupling agent, and 7% calcium oxide;

[0042] The mass ratio of component I and component II is 110:1.

[0043] The production process is as follows:

[0044] (1) Add softening oil and aromatic oil to asphalt at 160°C in turn, stir and heat up to 190°C, add rubber powder, shear and grind for 30 minutes, add modifier and extension agent, stir for 1 hour, add petroleum resin Stir for 40 minutes, add filler and anti-agin...

Embodiment 2

[0047] A non-curing rubber asphalt waterproof coating for wet ground, consisting of component I and component II:

[0048] The component I (non-curing component) is made of the following raw materials in weight percentage: 50% of high-grade asphalt, 7% of softened oil, 10% of aromatic oil, 7% of modifier, 2% of extension agent, rubber powder 5%, petroleum resin 5%, filler 13%, anti-aging agent 1%;

[0049] The component II (wet interface material) is made of the following raw materials in weight percentage: ethyl acetate 41%, rosin resin 45%, titanate coupling agent 4%, calcium oxide 10%;

[0050] The mass ratio of the component I to the component II is: 110:1.

[0051] Production technology is with embodiment 1.

Embodiment 3

[0053] A non-curing rubber asphalt waterproof coating for wet ground, consisting of component I and component II:

[0054] The component I (non-curing component) is made of the following raw materials in weight percentage: 10% of high-grade asphalt, 20% of softened oil, 30% of aromatic oil, 8% of modifier, 1.2% of extension agent, rubber powder 5%, petroleum resin 10%, filler 15%, anti-aging agent 0.8%;

[0055] The component II (wet interface material) is made of the following raw materials in weight percentage: 70% ethyl acetate, 18% rosin resin, 2% titanate coupling agent, and 10% calcium oxide;

[0056] Described component I and component II mass ratio are: 110:1

[0057] Production technology is with embodiment 1.

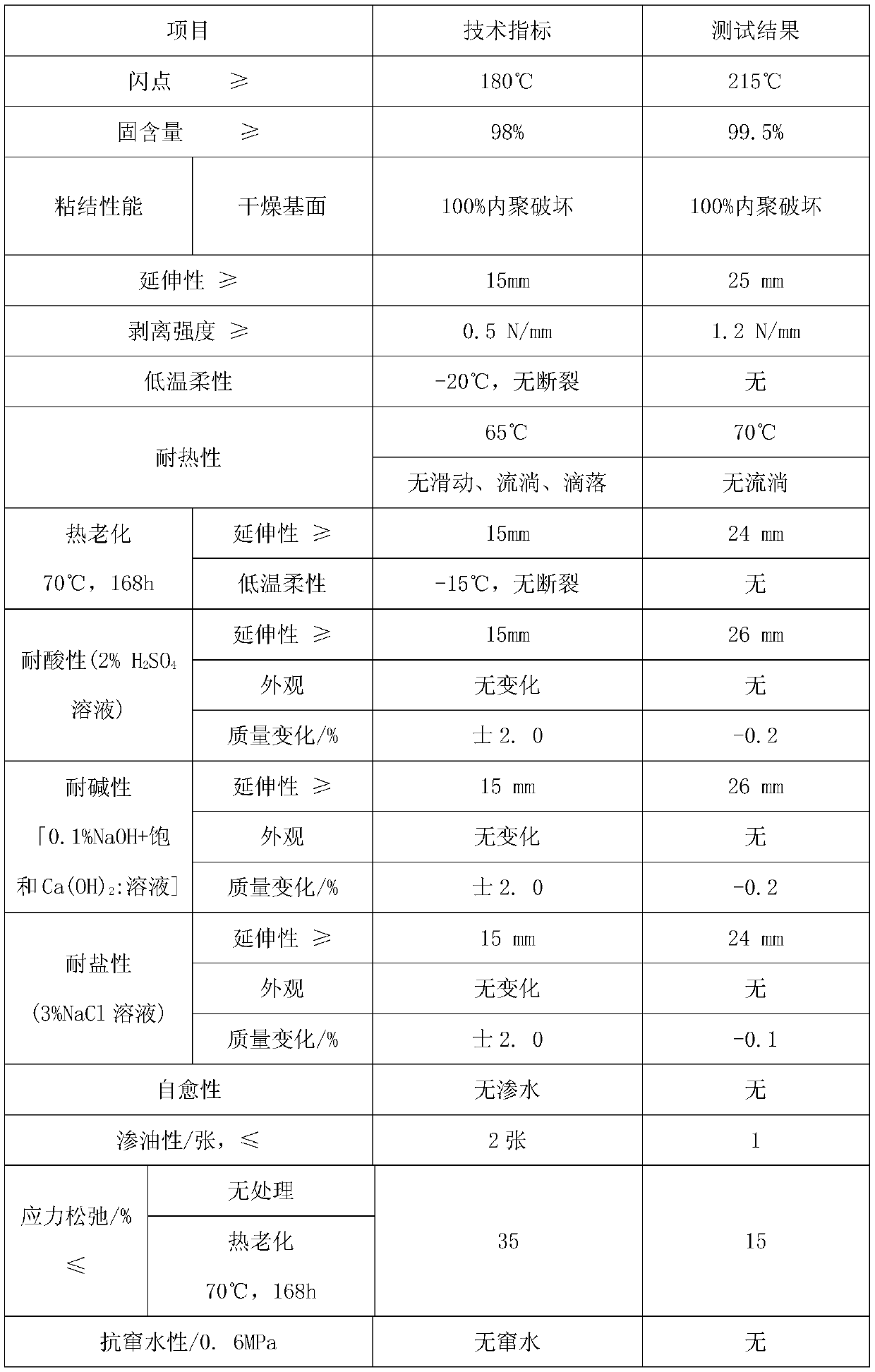

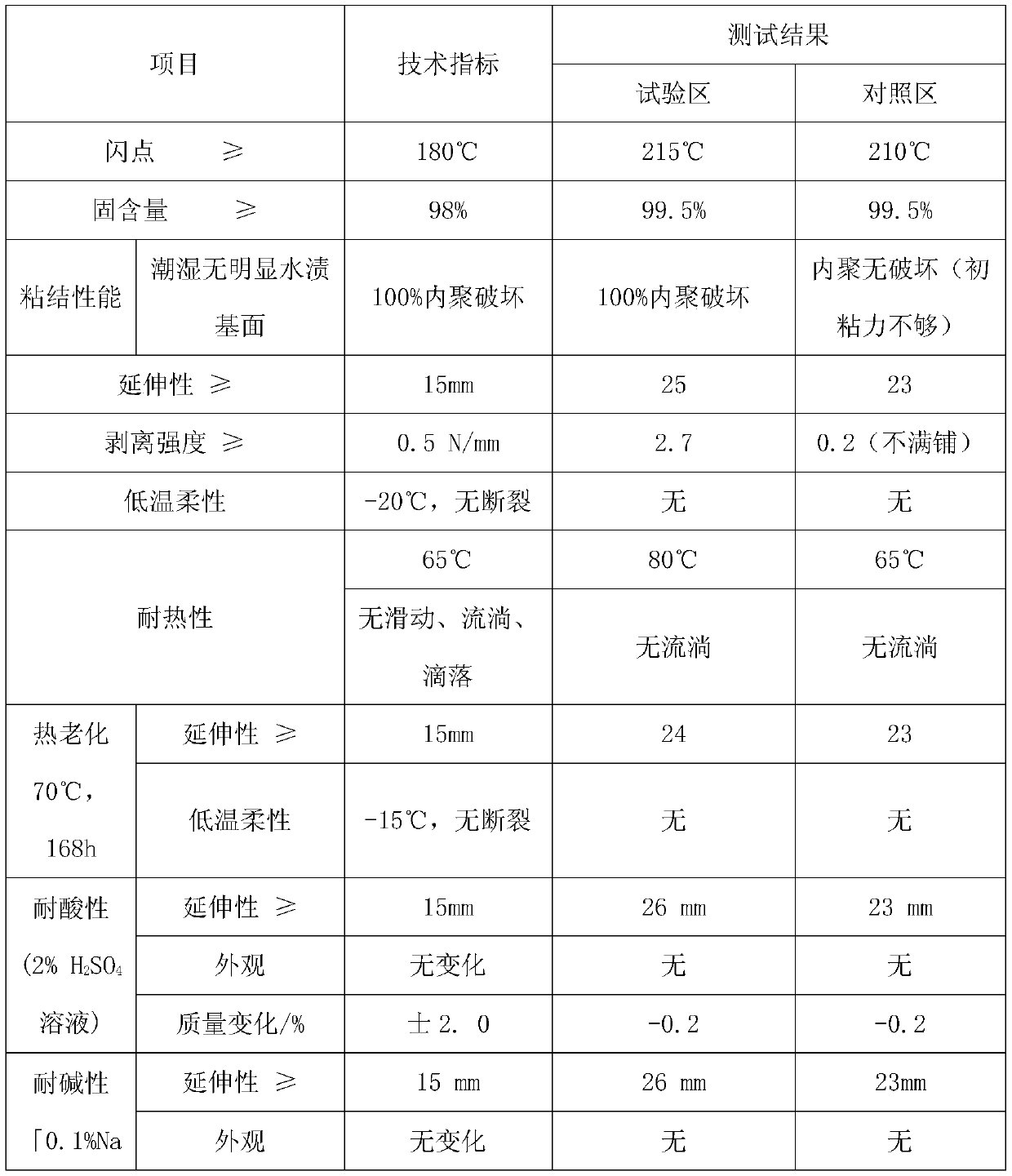

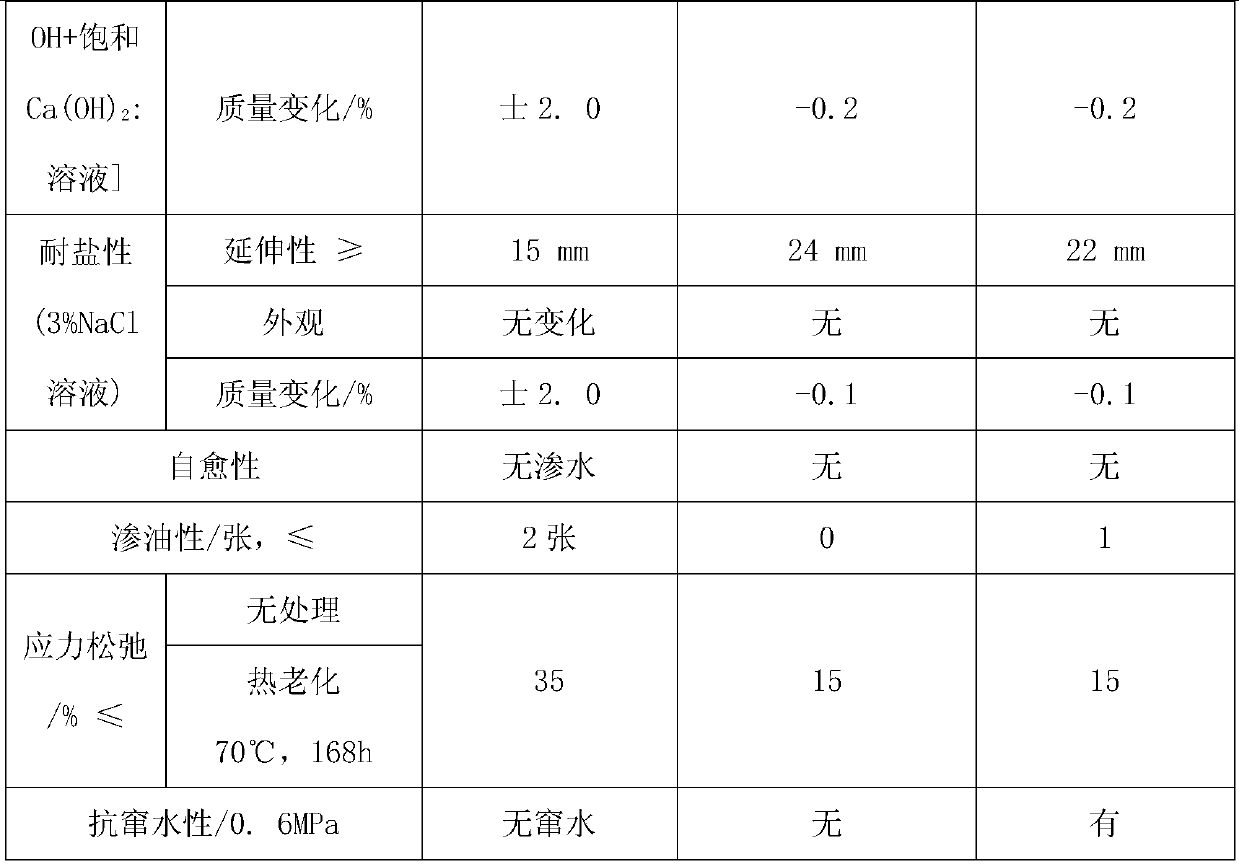

[0058] The coating component I prepared in Example 1-3 is detected with reference to the detection method specified in the national standard JC / T 24288-2017 "Non-curing Rubber Asphalt Waterproof Coating" (public draft), and the results are shown in Table 1 (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com