A kind of fast-setting rapid-hardening cement mortar and its extrusion process

A technology of fast-hardening cement and extrusion process, applied in the field of building materials, can solve problems such as irritation, and achieve the effects of low production cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

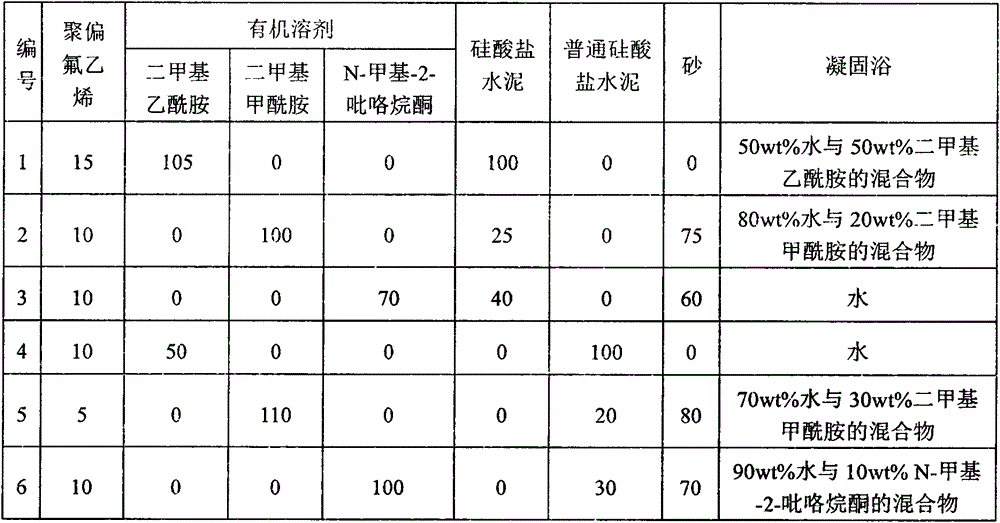

[0030] According to No. 1 formula in Table 1, first weigh 100g of Portland cement and pass it through a 20-mesh standard sieve. Next, 15 g of polyvinylidene fluoride was weighed, added to 105 g of dimethylacetamide, heated to 40° C., and vigorously stirred for 2 hours until the polyvinylidene fluoride was completely dissolved. At this time, the viscosity of the solution was 9 poise. Then, at room temperature, the above solution is added to the cement, and the mixture is stirred continuously until the mixture is uniform, so as to obtain the material for extrusion. The material for extrusion is loaded into an extrusion machine, and continuously extruded into a coagulation bath composed of 50 wt% water and 50 wt% dimethylacetamide, and the cement mortar is rapidly solidified and hardened.

Embodiment 2

[0032] According to No. 2 formula in Table 1, first weigh 25g of Portland cement and 75g of sand, pass through a 20-mesh standard sieve, and mix well. Next, 10 g of polyvinylidene fluoride was weighed, added to 100 g of dimethylformamide, heated to 50° C., and vigorously stirred for 3 hours until the polyvinylidene fluoride was completely dissolved. At this time, the viscosity of the solution was 8 poise. Then, at room temperature, the above solution is added to the cement, and the mixture is stirred continuously until the mixture is uniform, so as to obtain the material for extrusion. The material for extrusion is loaded into an extrusion machine, and continuously extruded into a coagulation bath composed of 80 wt% water and 20 wt% dimethylformamide, and the cement mortar is rapidly solidified and hardened.

Embodiment 3

[0034] According to No. 3 formula in Table 1, first weigh 40g of Portland cement and 60g of sand, pass through a 20-mesh standard sieve, and mix well. Next, 10 g of polyvinylidene fluoride was weighed, added to 70 g of N-methyl-2-pyrrolidone, heated to 60° C., and vigorously stirred for 4 hours until the polyvinylidene fluoride was completely dissolved. At this time, the viscosity of the solution was 15 poise. Then, at room temperature, the above solution is added to the cement, and the mixture is stirred continuously until the mixture is uniform, so as to obtain the material for extrusion. Put the material for extrusion into the extrusion machine, and continuously extrude it into the water, and the cement mortar will quickly solidify and harden.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com