Plastifying method of hydroxyl-terminated polymer

A technology of hydroxyl-terminated polymers and plasticizers, applied in the field of composite materials, can solve problems such as energy loss, poor HTPB compatibility, and poor plasticizing effects, and achieve excellent mechanical properties, good plasticizing effects, and improved Effect of energy output level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

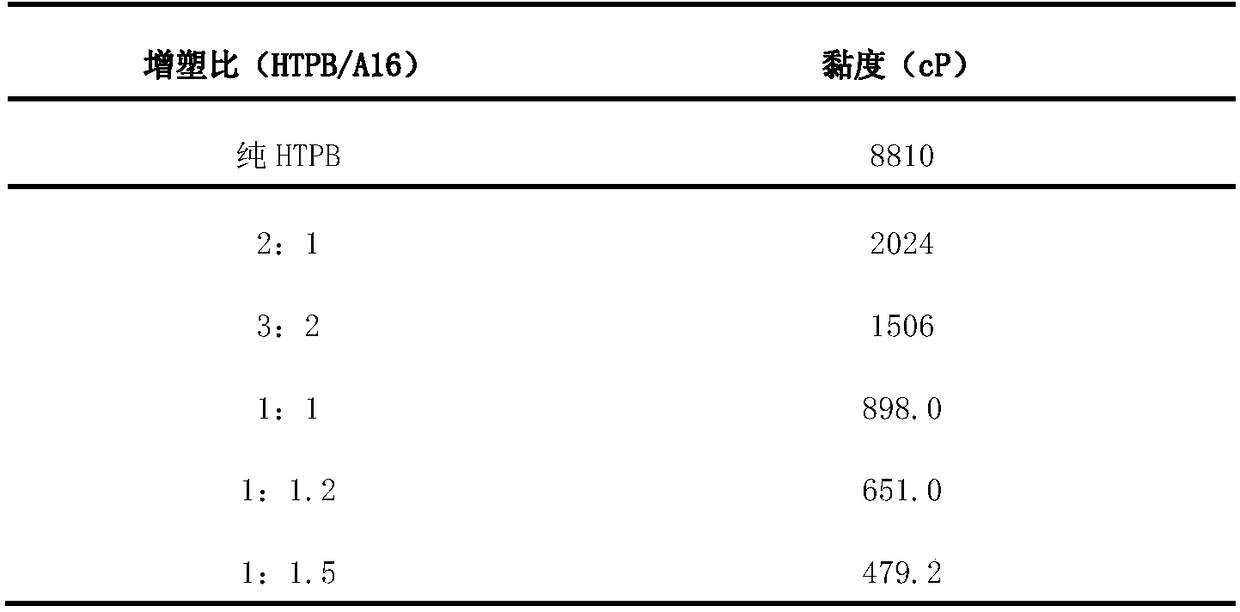

[0024] (1) 20g of HTPB liquid with a relative molecular weight of 2000 is weighed and placed in a conical flask;

[0025] (2) Weigh 10g of A16, add it into HTPB, stir rapidly with a magnetic stirrer, the stirring rate is 500r / min, and the stirring time is 300s;

[0026] (3) The mixed liquid is vacuum treated at -0.91Kpa for 600s.

Embodiment 2

[0028] (1) take by weighing 20g relative molecular weight and be that the HTPB liquid of 3000 is placed in the round bottom flask;

[0029] (2) Weigh 20g of A16, add it into HTPB, stir rapidly with an electric mixer, the stirring rate is 300r / min, and the stirring time is 600s;

[0030] (3) The mixed liquid is vacuum treated at -0.92Kpa for 600s.

Embodiment 3

[0032] (1) taking by weighing 300g relative molecular weight is that the HTPB liquid of 5000 is placed in the kneader;

[0033] (2) Weigh 200g A16, add it into HTPB, and stir it with a kneader, the stirring rate is 50r / min, and the stirring time is 1800s;

[0034] (3) The mixed liquid is vacuum treated at -0.91Kpa for 900s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com