Primer-free electronic detonator and control method thereof

An electronic detonator, no detonator technology, used in circuits, electrical components, weapon accessories, etc., can solve the problems of high cost, large volume, complex system structure, etc., to reduce cost and volume, improve action accuracy, and improve safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

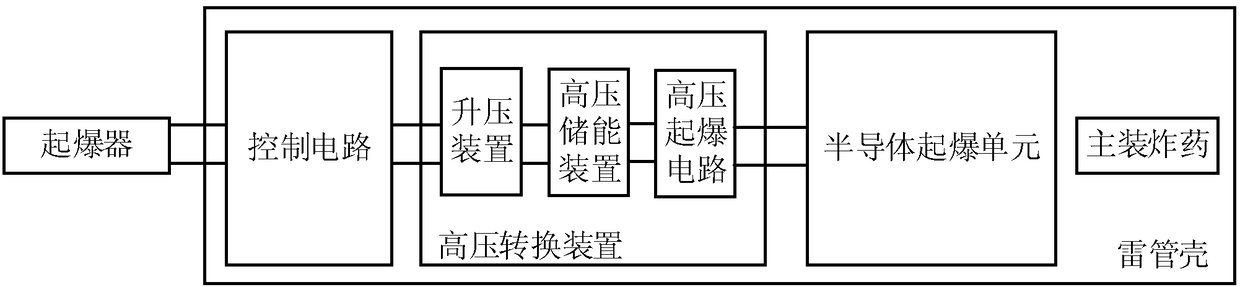

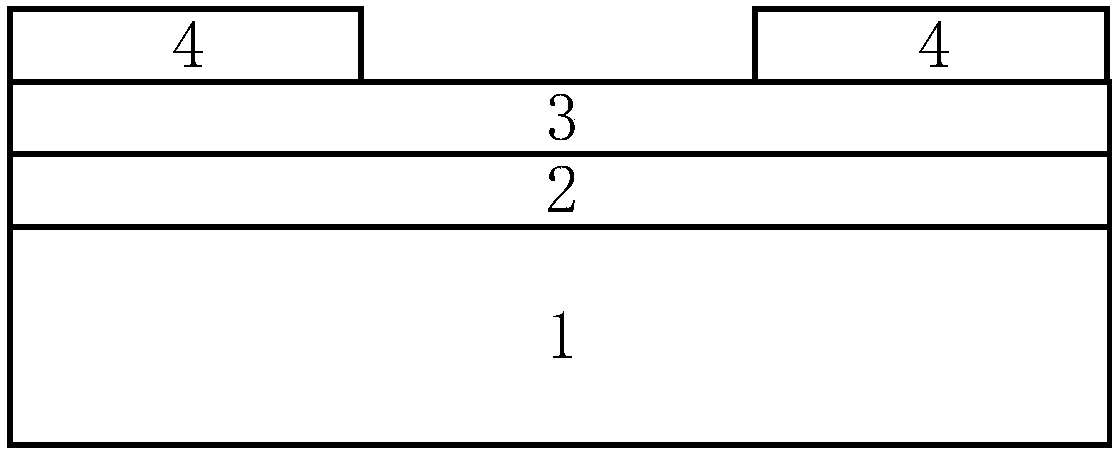

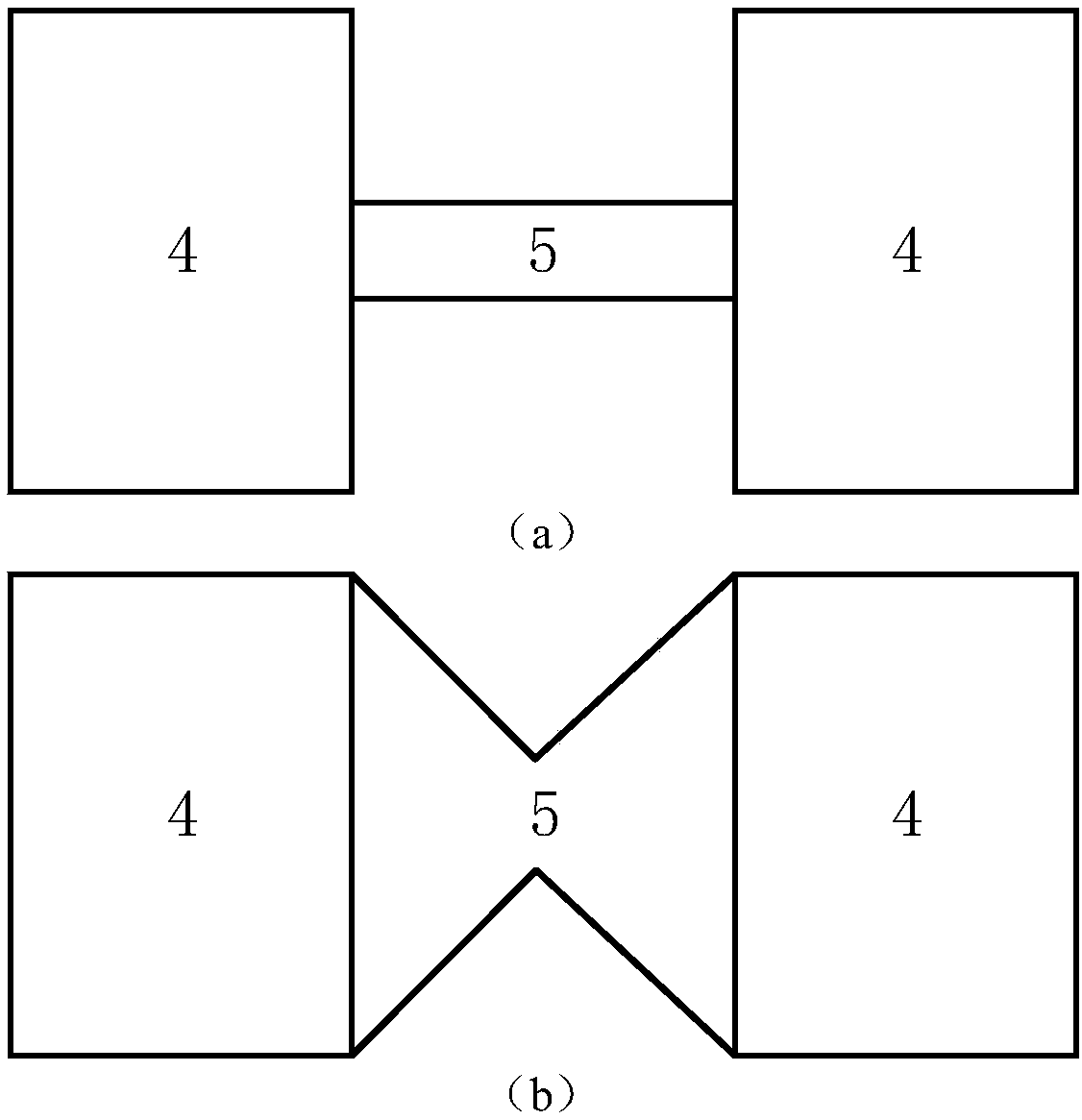

[0025] Such as figure 1 As shown, the non-primer electronic detonator of this embodiment includes: a control circuit, a high-voltage conversion device, a semiconductor detonating unit, a main explosive and a detonator shell; wherein, the control circuit, the high-voltage conversion device, the semiconductor detonation unit and the main explosive are packaged in In the detonator shell; the detonator located outside the detonator shell is electrically connected to the control circuit; the control circuit is electrically connected to the high-voltage conversion device; the high-voltage conversion device is electrically connected to the semiconductor detonation unit; the detonation area of the semiconductor detonation unit is facing the main explosive; The explosive is cylindrical, and the end face faces the detonation area of the semiconductor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com