High-speed bearing performance testing machine

A testing machine and bearing technology, which is applied in the direction of mechanical bearing testing, mechanical component testing, machine/structural component testing, etc., can solve problems such as the inability to provide ultra-high-speed durability test conditions, limited machine test capabilities, and difficulty in meeting production requirements. , to achieve the effect of reducing inertia, small loading force error and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

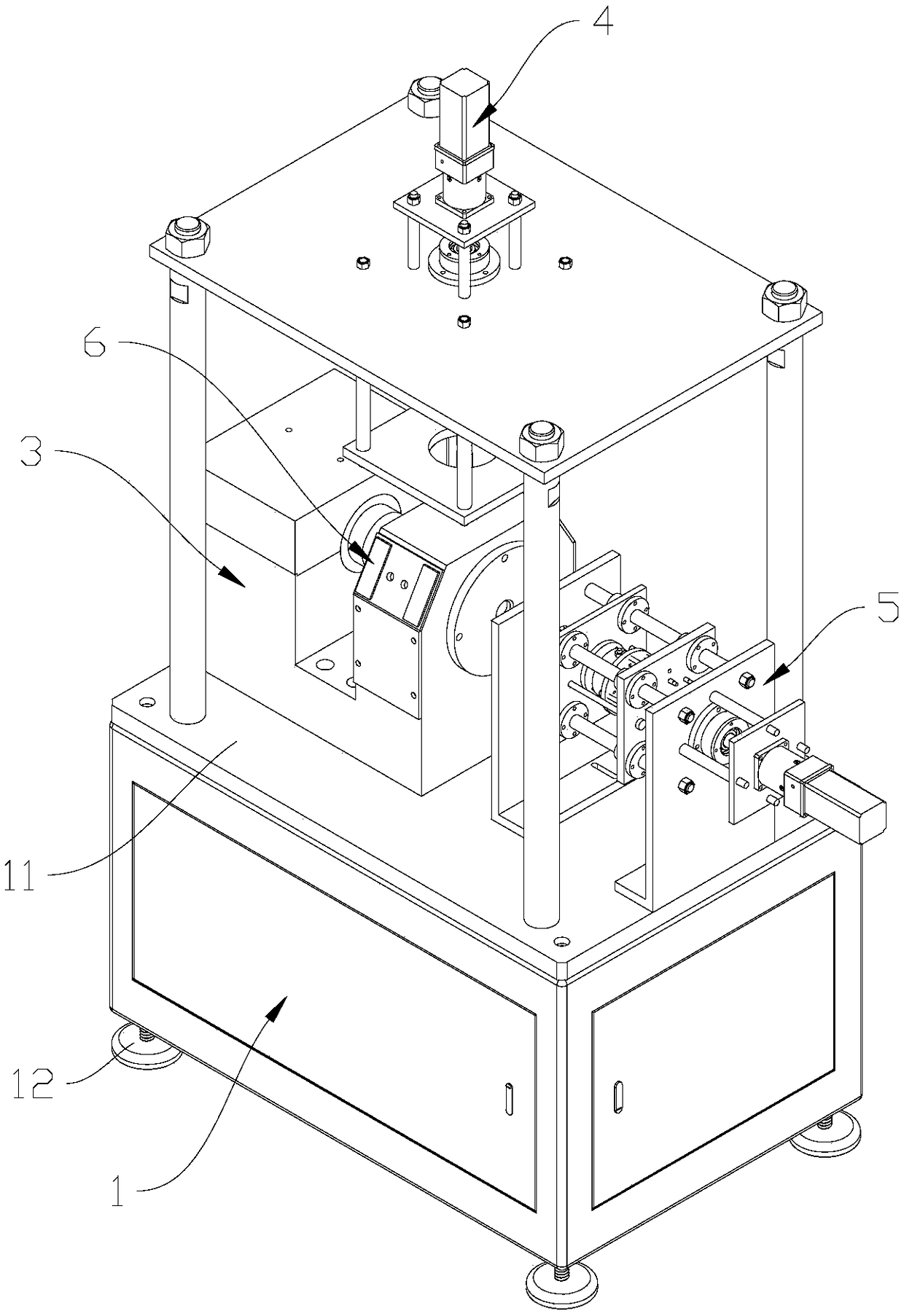

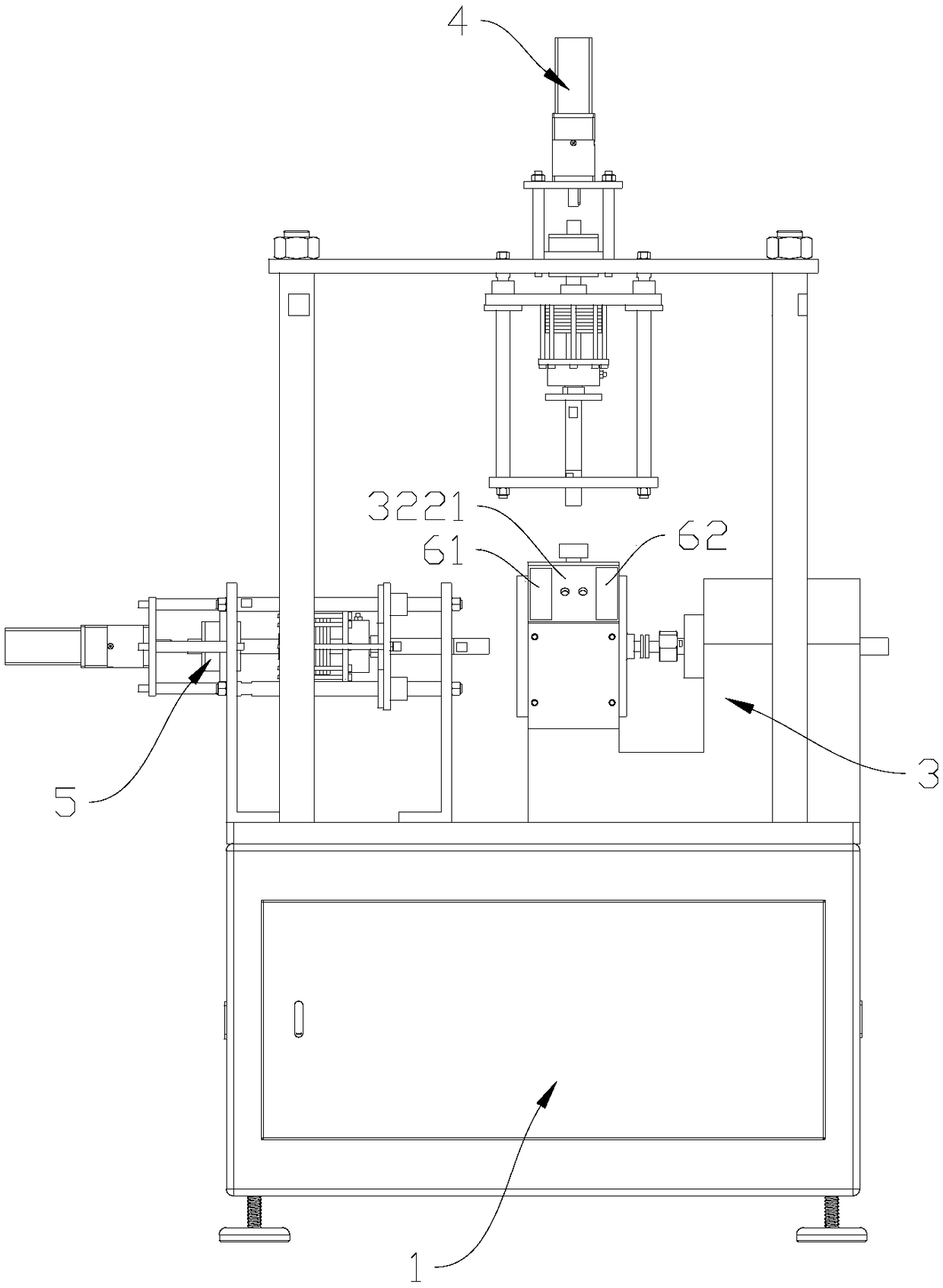

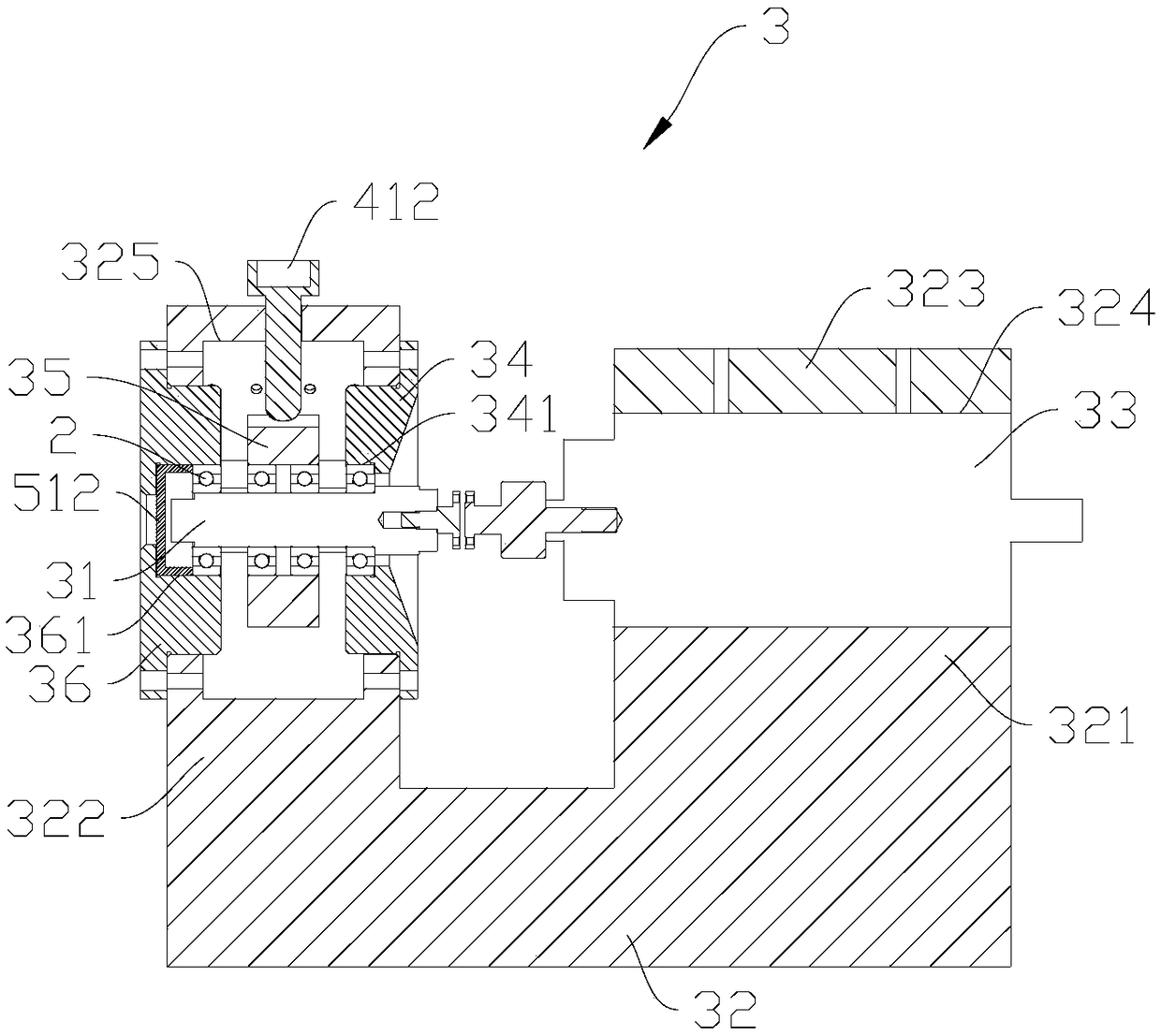

[0043] This embodiment discloses a bearing high-speed performance testing machine, which combines Figure 1 to Figure 3 As shown, it includes a stand 1, a bearing drive module 3 arranged on the stand 1 for installing the test bearing 2 to be tested and driving the test bearing 2 to rotate, and a radial loading module for applying a radial loading force to the test bearing 2. Module 4, an axial loading module 5 for applying axial loading force to the test bearing 2, a detection module 6 for detecting the surface temperature and vibration times of the test bearing 2, and a module 4 for setting the radial loading and axial loading The loading force of the module 5 and the operating module for visually outputting the information detected by the detection module 6, wherein the stand 1 includes a desktop 11 and feet 12 for supporting the desktop 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com