Novel high-intensity waterproof watch and watch case processing method thereof

A high-strength, watch technology, applied in the field of daily wearables, can solve problems such as bulky watches, achieve the effects of low cost, enhanced mechanical properties, and improved waterproof capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

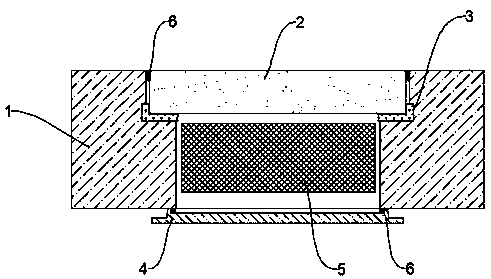

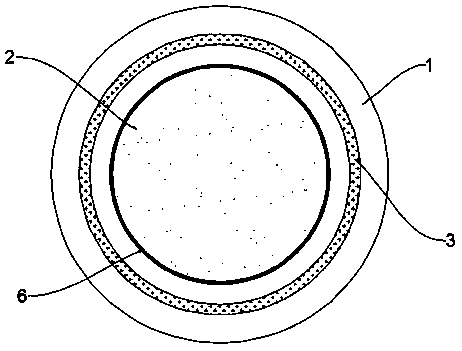

[0024] see Figure 1~2 , in the embodiment of the present invention, a novel high-strength waterproof watch includes a watch case 1, and a watch movement 5 is installed in the watch case 1; the watch case 1 is injection-molded by engineering plastics or fiber reinforced plastics. Compared with the metal watch case, it has better anti-drop and anti-scratch performance, and at the same time, it is molded at one time, without the need for post-processing, and the cost is lower. The watch case 1 is equipped with a glass mirror 2 and a back cover 4, of which the glass mirror 2 is One of mineral strengthened glass mirrors, acrylic strengthened glass mirrors, and sapphire crystal glass mirrors. Preferably, in this embodiment, the glass mirror 2 is a mineral strengthened glass mirror with high cost performance. Further, the glass mirror 2 The connection with the watch case 1 and the connection between the back cover 4 and the watch case 1 are all provided with a sealing ring 6 to prev...

Embodiment 2

[0028] A method for processing a watch casing, comprising the following steps:

[0029] 1) Use high-strength alloys to make metal brackets;

[0030] 2) Make a mold that matches the watch case, and then bury a metal bracket at the position corresponding to the glass mirror;

[0031] 3) Send engineering plastic solid particles into the screw pusher, use high temperature to melt engineering plastic solid particles and then generate high pressure through screw stirring to inject liquid plastic into the mold;

[0032] 4) After the liquid plastic is solidified, remove the mold, and the product is ready.

Embodiment 3

[0034] A method for processing a watch casing, comprising the following steps:

[0035] 1) Use high-strength alloys to make metal brackets;

[0036] 2) Make a mold that matches the watch case, and then bury a metal bracket at the position corresponding to the glass mirror;

[0037] 3) Feed the fiber-reinforced plastic solid particles into the screw pusher, use high temperature to melt the engineering plastic solid particles, and then generate high pressure through screw stirring to inject liquid plastic into the mold;

[0038] 4) After the liquid plastic is solidified, remove the mold, and the product is ready.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com