Superconducting magnet second-stage cooling apparatus and second-stage cooling method

A technology for superconducting magnets and secondary cooling, which is applied in the direction of superconducting magnets/coils, magnetic objects, electrical components, etc., can solve problems such as unavoidable, unreasonable economics, and adverse effects on the performance of superconducting coils, and achieve cost savings, The effect of ensuring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

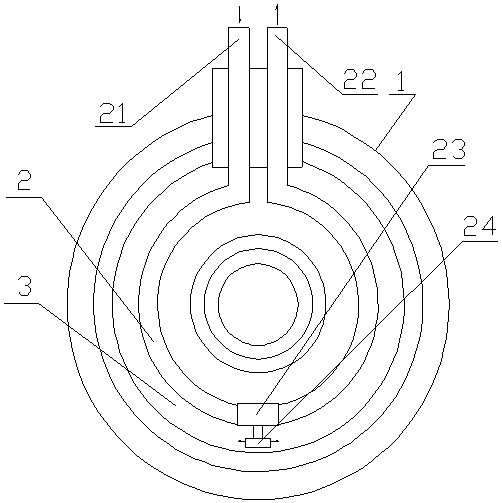

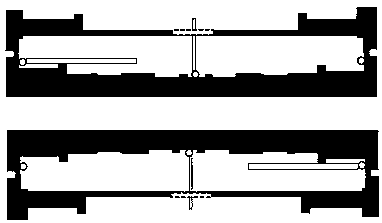

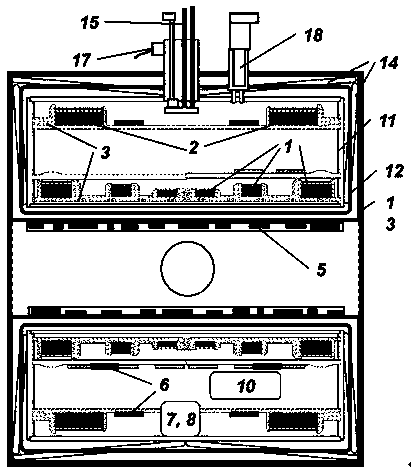

[0013] Embodiment 1: with reference to attached figure 1 and 2 . A secondary cooling device for a superconducting magnet includes a superconducting magnet cooling device 1. The manufacture of the superconducting cooling device 1 is based on the prior art, and will not be described here. In the present invention, on the basis of the superconducting magnet cooling device 1, a cooling pipeline 2 is provided in the liquid helium container 3 in the superconducting magnet cooling device. At the outlet, a three-way control valve 23 is connected in series in the cooling pipeline 2 and the outlet of the three-way control valve 23 communicates with the cavity of the liquid helium container 3 .

[0014] The cooling pipeline 2 is one group or multiple groups, whether it is one group or multiple groups, the cooling pipeline 2 is in contact with the coil surface of the superconducting magnet located in the liquid helium container 3, and the cooling pipeline 2 is provided with heater.

...

Embodiment 2

[0019] Embodiment 2: On the basis of Embodiment 1, a cooling method of a superconducting magnet secondary cooling device, 1) liquid nitrogen passes through the refrigeration of the cooling pipeline 2 in the liquid helium container 3, so that the liquid helium valve container 3 The superconducting magnet inside is cooled from room temperature to minus 200°C (-77K); 2) Use pressurized fluid to drive liquid nitrogen from the cooling pipeline 2 to the top of the container for release; 3) Connect it in series to the cooling pipeline 2 The three-way control valve 23 is opened, and since the outlet of the three-way control valve 23 is connected to the liquid helium container 3, the liquid helium is injected into the cooling pipeline 2 at this time because the three-way control valve 23 liquid outlet connected in series on the cooling pipeline enters the liquid helium container 3 Inside, liquid helium cools the superconducting magnet to the predetermined magnet operating temperature -2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com