Explosion-proof ceramic capacitor

A ceramic capacitor, explosion-proof technology, used in capacitors, fixed capacitor casings/packages, fixed capacitor parts and other directions, can solve problems such as inconvenient packaging operations, capacitor explosions, and troublesome packaging operations, to improve overall safety performance, extend the Long service life and good explosion-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

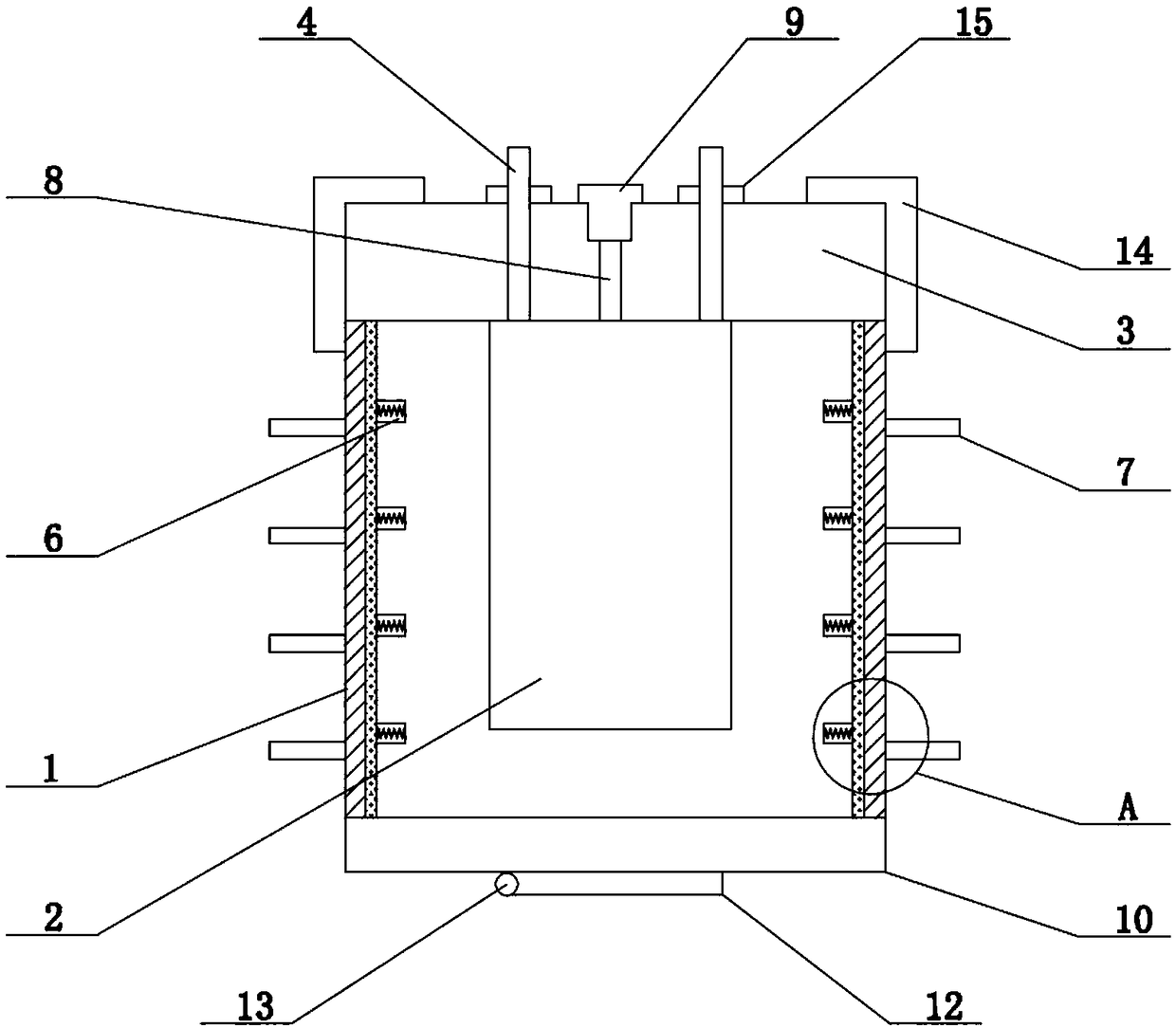

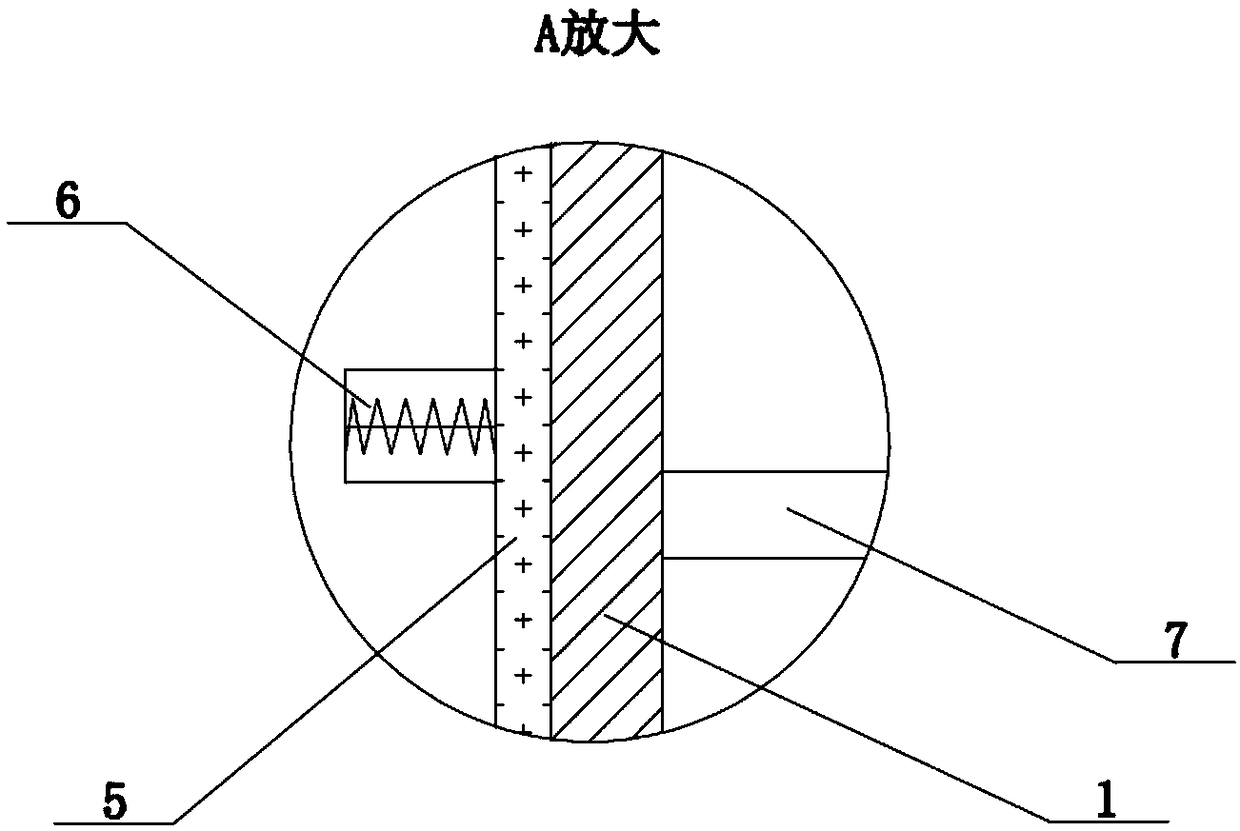

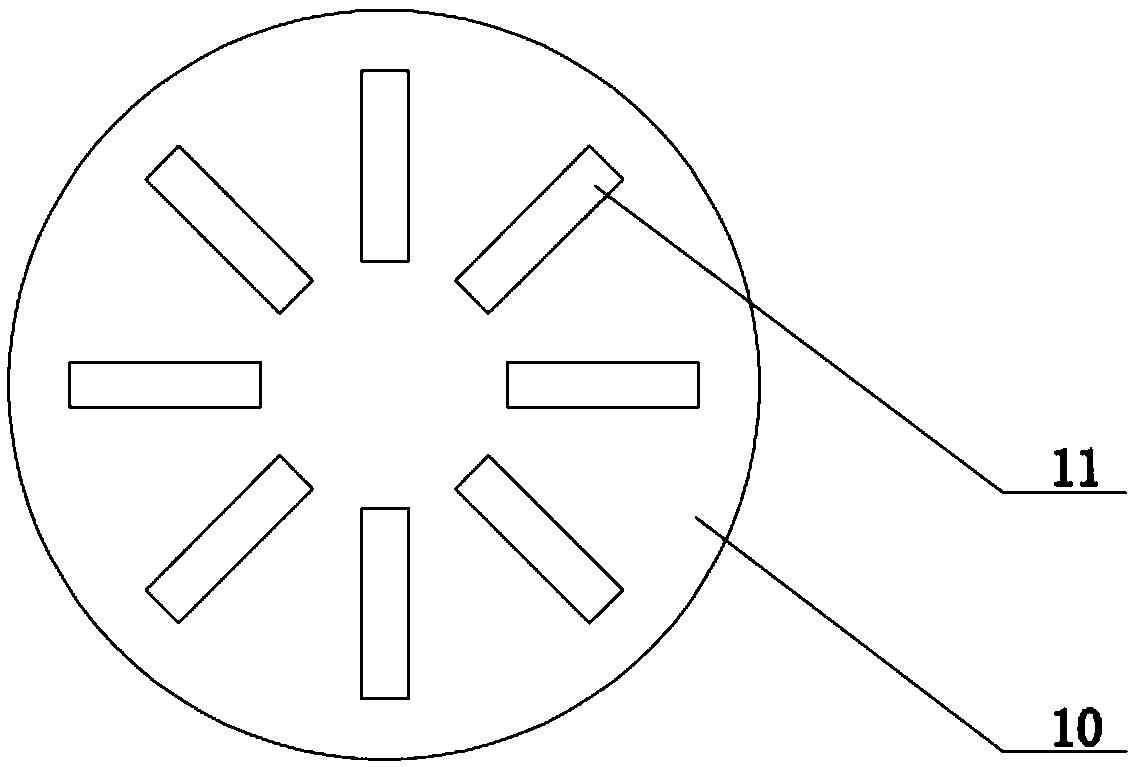

[0017] see Figure 1-Figure 3 As shown, the technical solution adopted in this specific embodiment is: it includes a shell 1, a capacitor chip 2, a sealing end cover 3, and a pin 4, and it also includes a foam metal layer 5, a spring ring 6, a metal heat sink 7, and a heat dissipation channel 8. Plug 9, explosion-proof base 10, exhaust channel 11, cover plate 12, capacitor chip 2 is located in the shell 1, the inner surface of the shell 1 is covered with a foam metal layer 5, and the foam metal layer 5 is provided with a plurality of A spring ring 6, a plurality of metal heat sinks 7 are welded on the outer surface of the housing 1, a sealing end cover 3 is arranged on the upper part of the housing 1, two pins 4 are connected to the capacitor chip 2, and the two pins 4 pass through the sealing The end cover 3 extends out of the shell 1, and the middle part of the sealing end cover 3 is provided with a heat dissipation channel 8, and the outlet end of the heat dissipation chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com