EPS and motor control method and device and temperature detection method and device therefor

A technology of motor control and motor temperature, which is applied in the EPS field, can solve the problems of difficult motor, motor function decline, burnout, etc., and achieve the effect of preventing burnout, preventing function decline, and good adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

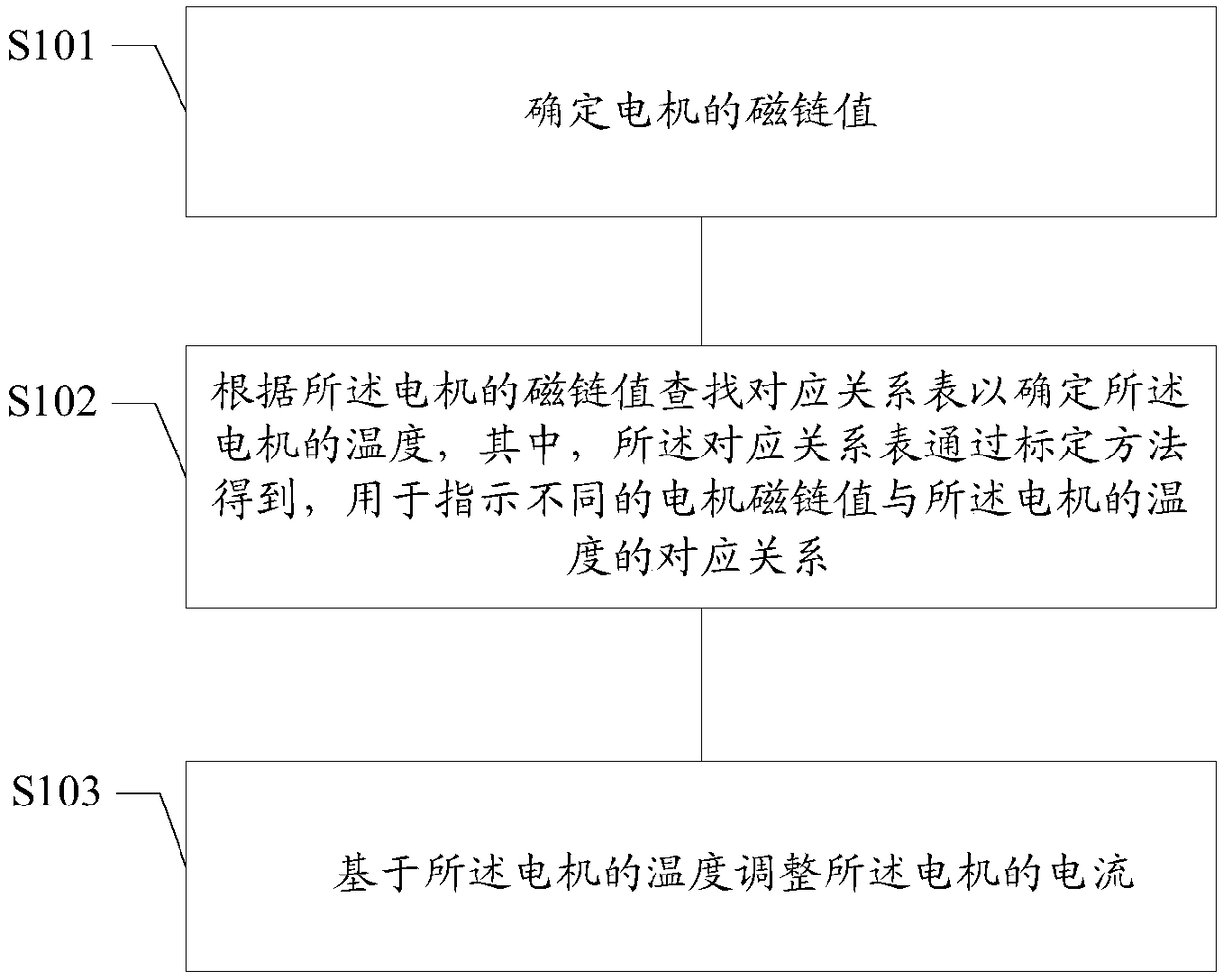

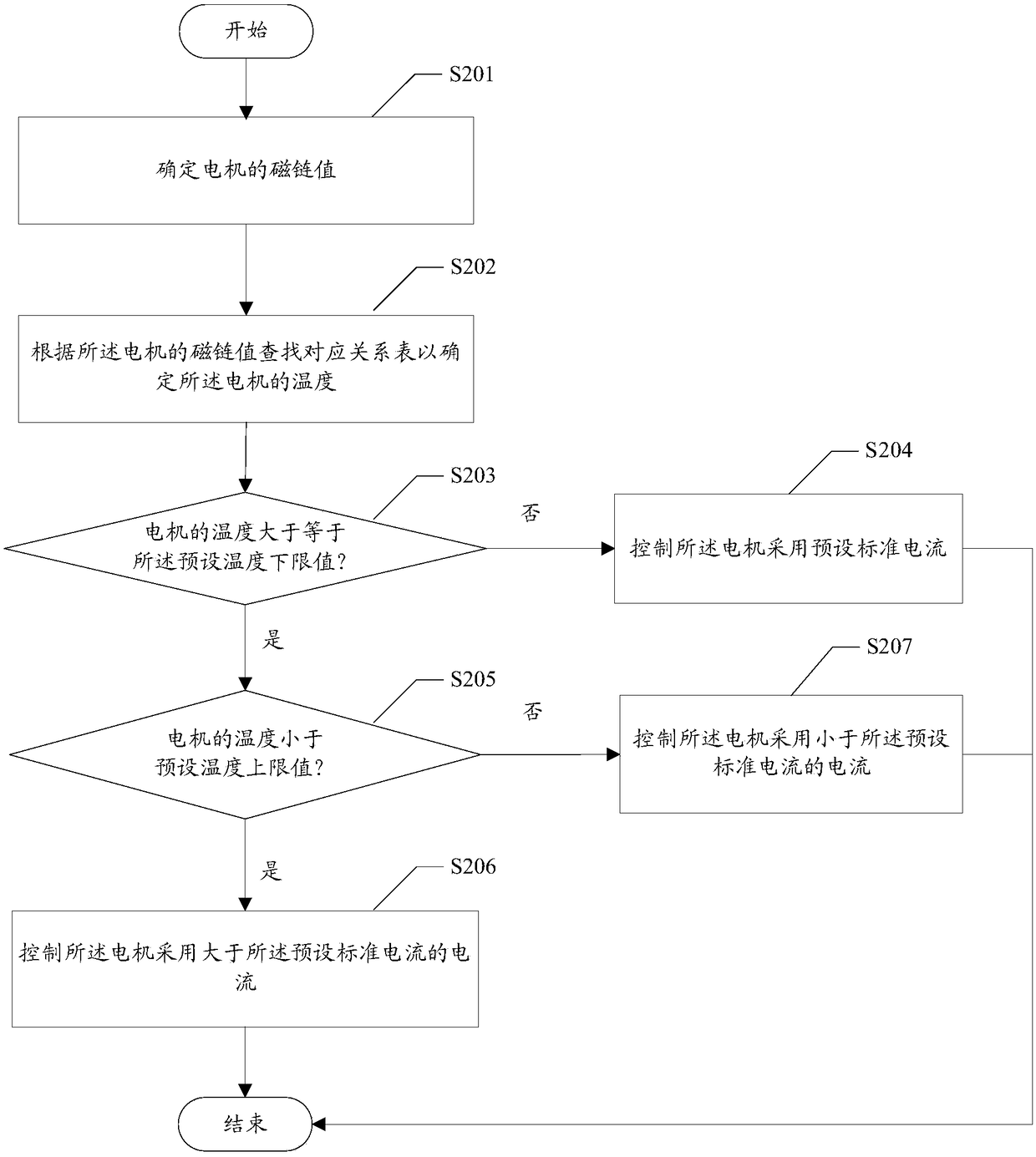

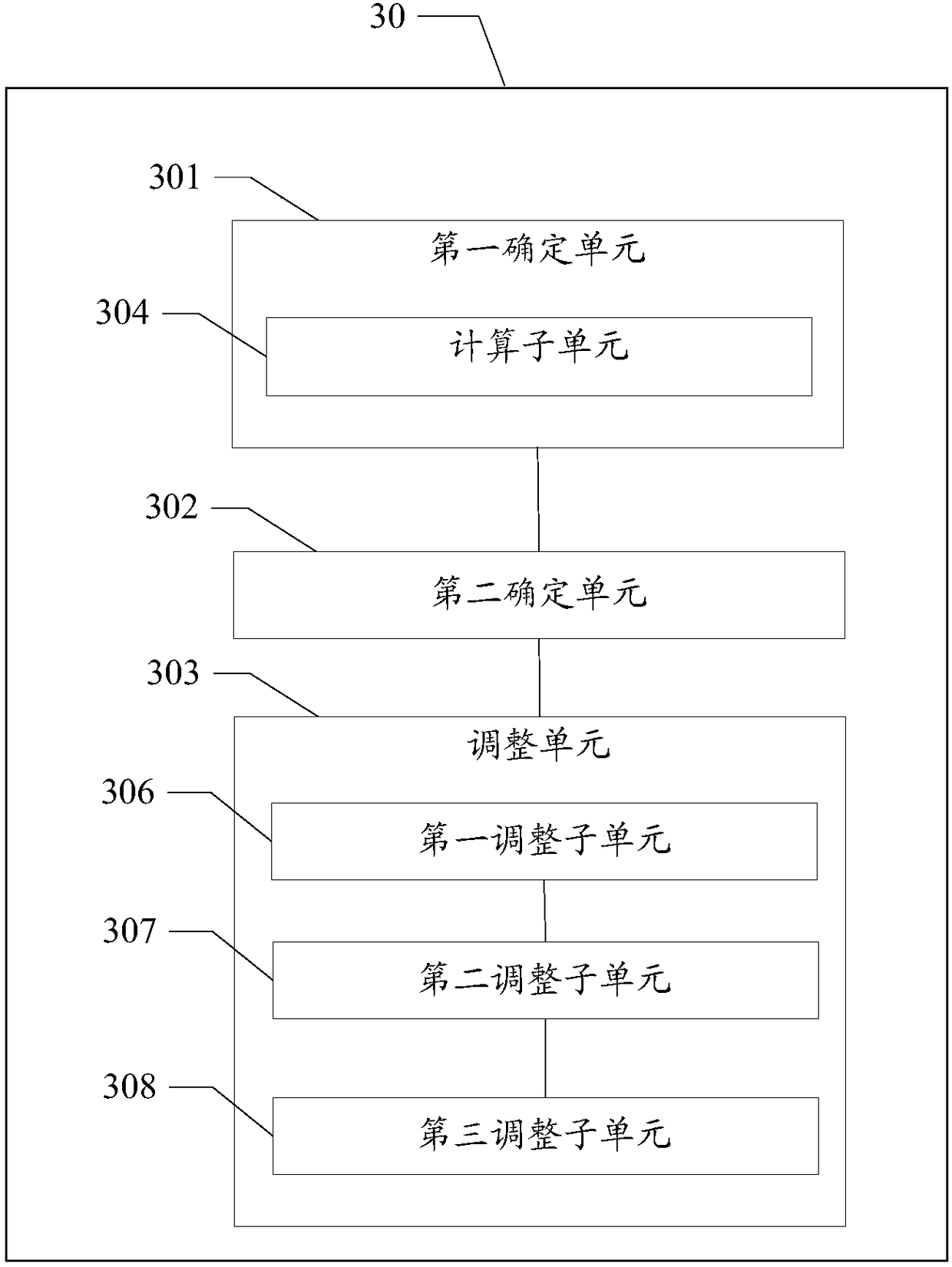

Method used

Image

Examples

Embodiment Construction

[0040] As mentioned above, in one measure of the prior art, the temperature of the motor of the EPS is obtained by using an indirect measurement method, such as installing a temperature sensor in the ECU, and estimating the temperature of the motor by measuring the temperature around the temperature sensor inside the ECU . However, in actual operation, the above estimation method has a large deviation, and the obtained motor temperature is often not accurate enough. Because it is difficult to obtain accurate motor temperature, it is also difficult to control the motor reasonably, and it is easy to cause the function of the motor to decline at high temperature, or even be burned.

[0041] The inventors of the present invention have found through research that the key to the above problem is that the corresponding relationship between the temperature inside the ECU and the temperature inside the motor is too weak. Specifically, the internal structure and external environment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com