Hydraulic plate pressing machine

A plate press and hydraulic technology, applied in the field of hydraulic plate press, can solve the problems of large amount of manual labor, troublesome, inability to ensure the uniformity of sheet materials, etc., and achieve the effect of reducing labor amount and good adjustment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

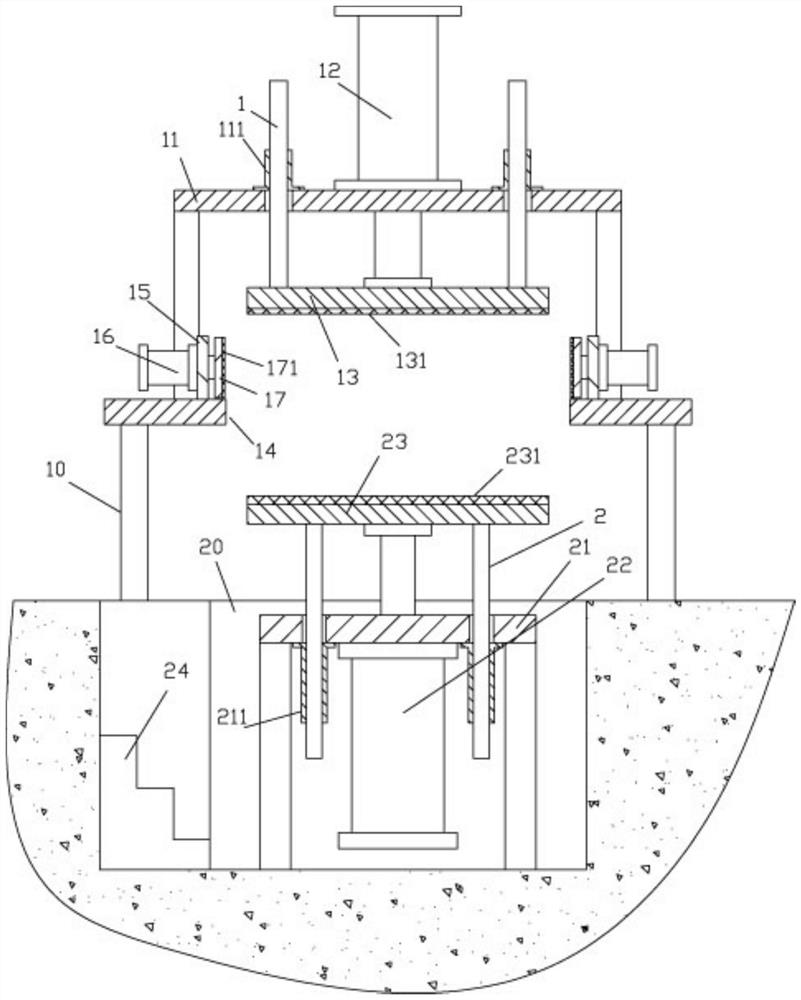

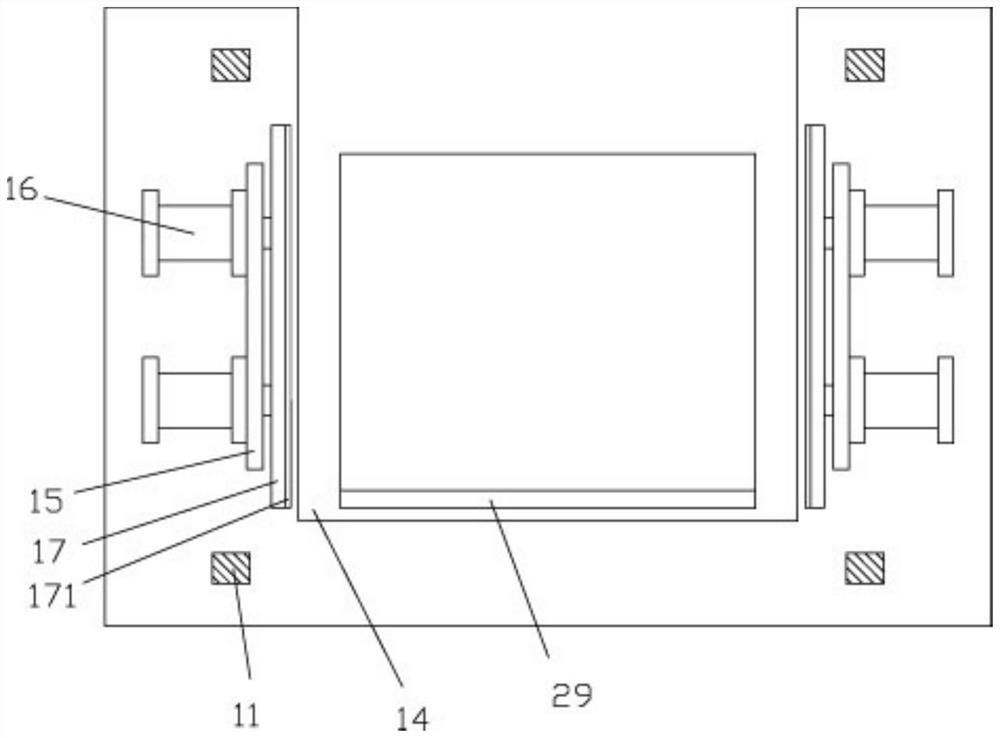

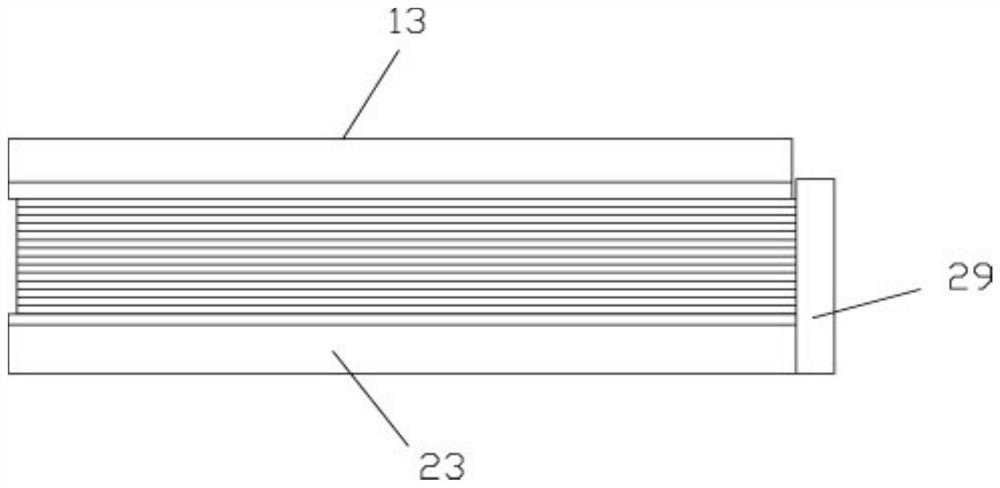

[0020] Examples, see as Figure 1 to Figure 3 As shown, a hydraulic press includes a support frame 10, the support frame 10 is fixed on the ground, the middle of the ground has a lower installation groove 20, the bottom surface of the lower installation groove 20 is fixed with a lower support frame 21, the lower support frame 21 The bottom surface of the top plate is fixed with a lower lift cylinder 22, and the push rod of the lower lift cylinder 22 passes through the top plate of the lower support frame 21 and is fixed with a lower lift plate 23;

[0021] The upper pressing support frame 11 is fixed on the top surface of the top plate of the supporting frame 10, and the upper pressing oil cylinder 12 is fixed in the middle of the top surface of the top plate of the upper pressing support frame 11, and the push rod of the upper pressing oil cylinder 12 passes through. The upper pressing plate 13 is fixed on the bottom surface of the top plate of the supporting frame 11. The up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com