Rapid filtering device for tea samples

A fast filtration and sample technology, applied in filtration separation, filtration loop, tea extraction, etc., can solve the problems of cumbersome filtration procedures, strong and unpleasant tea taste, color change, etc., to achieve a high degree of adjustment, ensure filtration quality, operation handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

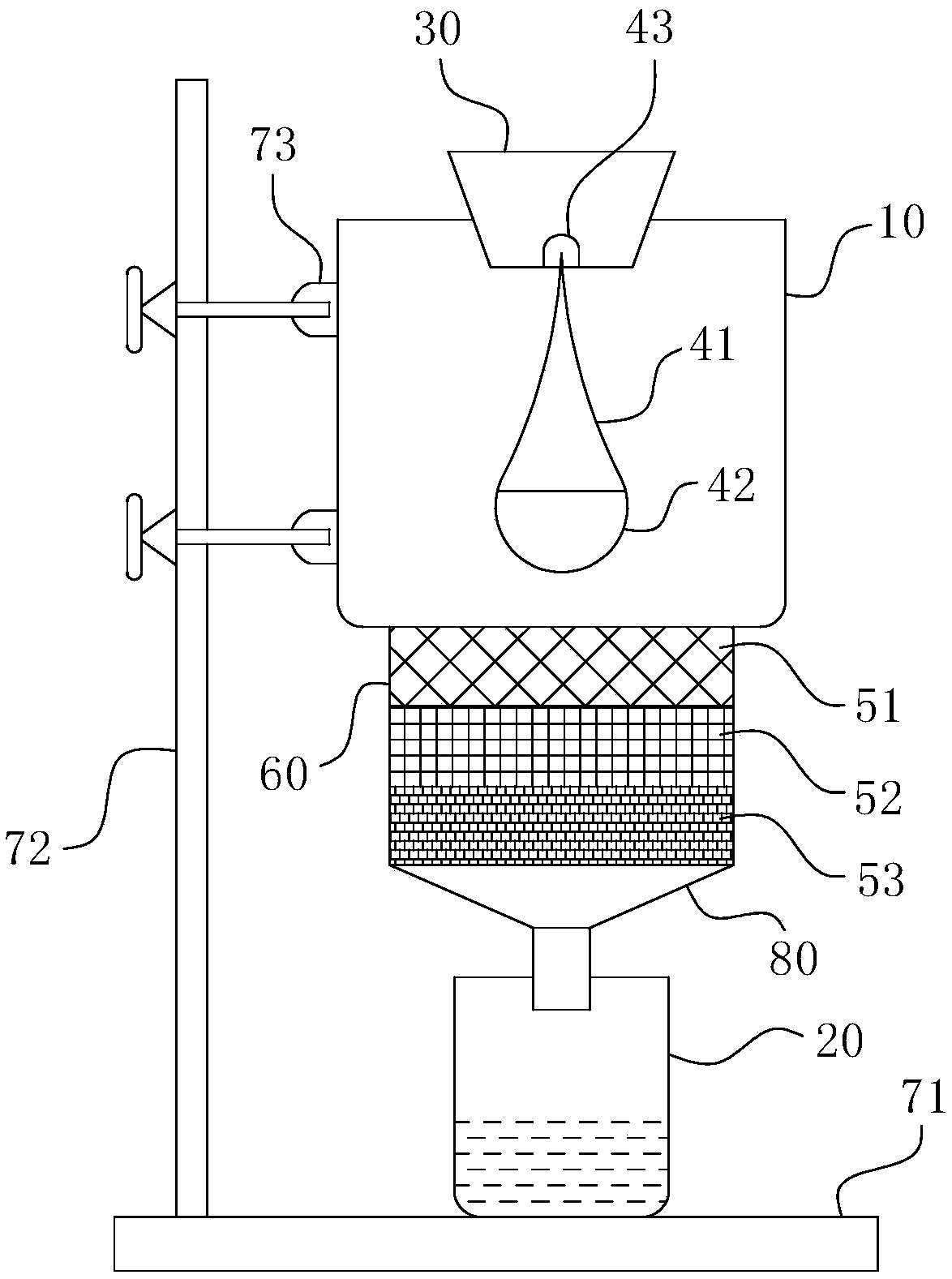

[0026] For ease of understanding, combined here figure 1 , the concrete structure and working mode of the present invention are further described as follows:

[0027] Concrete embodiment structure of the present invention refers to figure 1 As shown, its main structural part includes a bracket and a tank body 10 fixed on the bracket. The tank body 10 can be an open barrel structure; it can also be as figure 1 The closed tank structure shown is to facilitate the external isolation of tea extraction samples. The tank body 10 is fixed by the fixing clip 73, so that it can be adjusted vertically on the figure 1 On the support rod 72 shown.

[0028] A trumpet-shaped diversion sleeve 30 is embedded on the top wall of the tank body 10 . A power source 43 is arranged at the liquid outlet of the diversion sleeve 30 , and the power output shaft of the power source 43 extends vertically downward. exist figure 1 It can be seen from the shown structure that the power output shaft of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com