Preparation equipment and production process of water-based sound insulation coating

A sound insulation coating, water-based technology, applied in grain processing, transportation and packaging, mixers with rotary stirring devices, etc. problems, to avoid confusion, reduce labor costs, and simplify operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

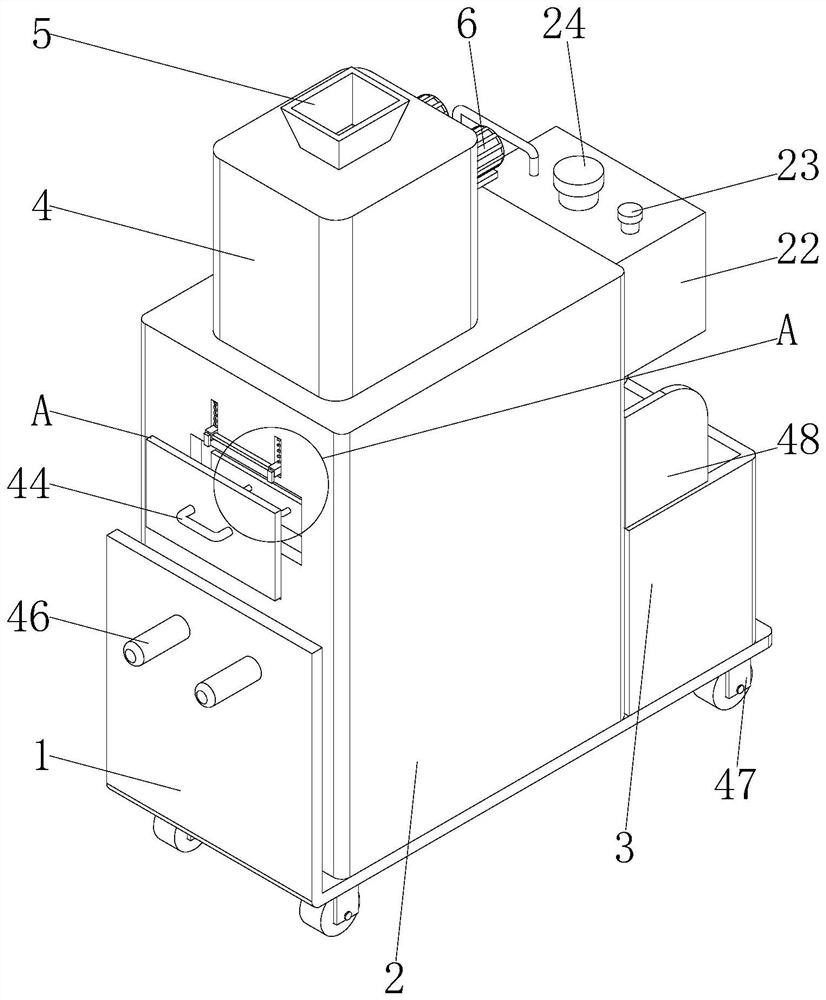

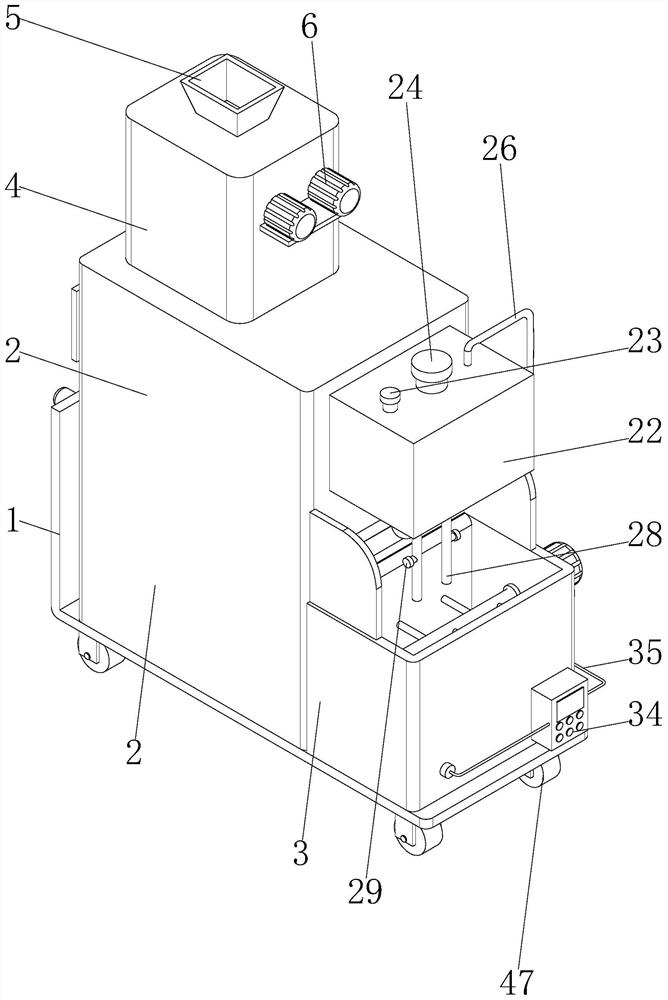

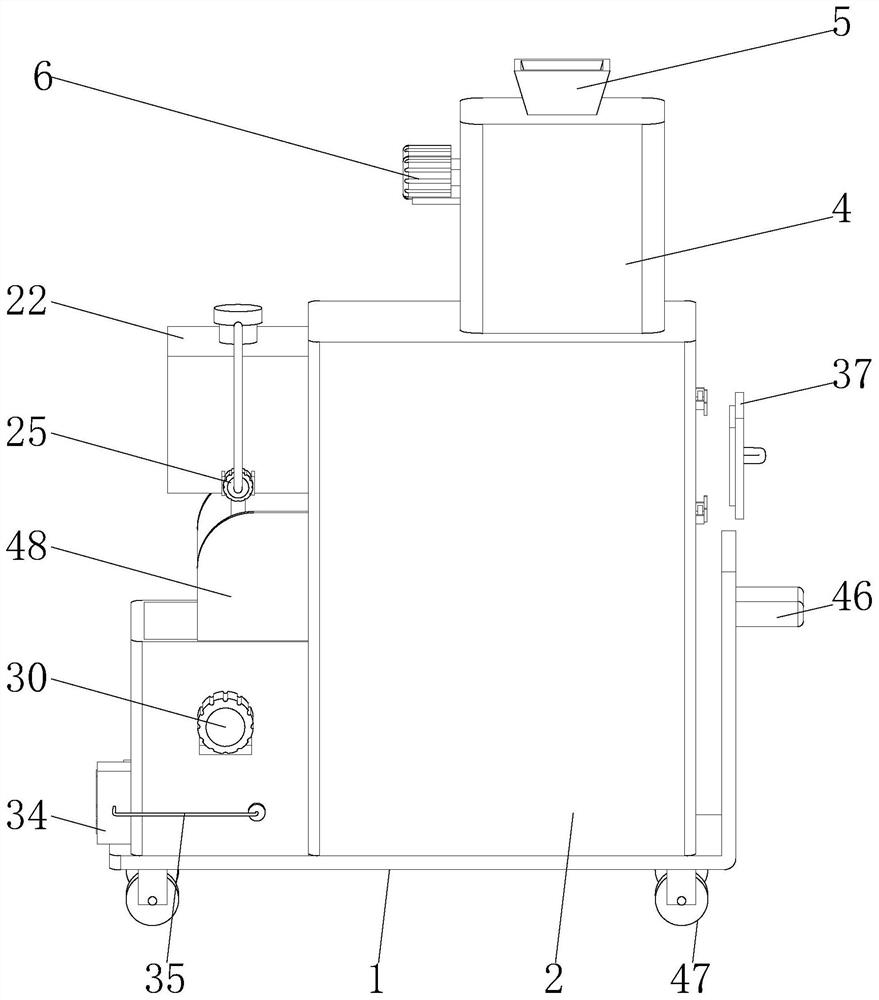

[0039] see Figure 1-7 , the present invention provides the following technical solutions: a water-based sound-proof paint preparation equipment, including a push car board 1, the upper end of the push car board 1 is fixedly connected with a treatment box 2 and a mixing box 3, and the upper end of the treatment box 2 is fixedly connected There is a crushing box 4, the upper end of the crushing box 4 is fixedly connected with a feed funnel 5, one side of the crushing box 4 is fixedly installed with a first motor 6, and the output end of the first motor 6 is fixedly connected with a shaft rotation rod 7, The outer surface of the shaft rotation rod 7 is fixedly connected with a crushing spiral blade 8, and the inner wall of the processing box 2 is vertically provided with a sliding groove 9, and the inner wall of the sliding groove 9 is slidably connected with a filter box 10 through a sliding block, and the inside of the processing box 2 The connecting plate 11 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com