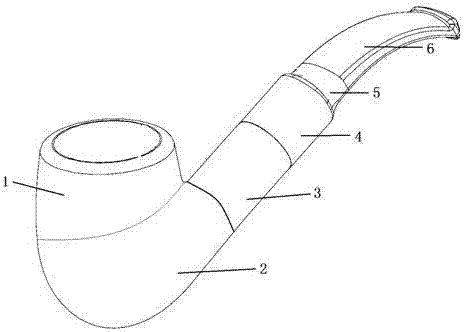

Multifunctional tobacco pipe and machining technology thereof

A processing technology and multi-functional technology, applied in the field of machinery, which can solve the problems of inconspicuous filtering of harmful substances, inability to meet the needs of use, and unsanitary conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

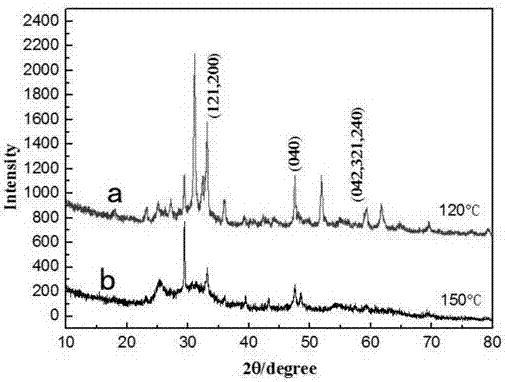

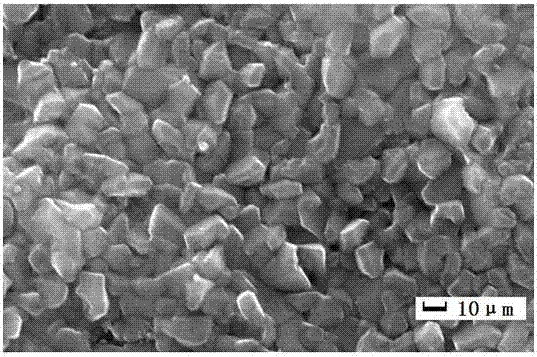

[0032] The filter body is a ceramic matrix, and the ceramic matrix is provided with a nano-inorganic film, the nano-inorganic film can allow liquid to pass through, and the thickness of the nano-inorganic film is 5 microns. The raw material components and weight ratio of the nano-inorganic thin film are: 10 parts of alumina, 5 parts of silicon oxide, 1 part of titanium oxide, 2 parts of yttria-stabilized zirconia, 4 parts of titanium carbide, 1 part of activated carbon fiber, 1 part of magnesium, 5 parts of boron nitride.

[0033] The fingerprint scanning device includes an inorganic non-metallic coating arranged on the fingerprint, and the raw material type and weight ratio of the coating are: 50 parts of silicon oxide, 1 part of boron oxide, 5 parts of potassium oxide, and 15 parts of barium oxide , 4 parts of zinc oxide, 1 part of titanium oxide, 1 part of aluminum oxide, and 1 part of tungsten oxide.

Embodiment 2

[0035] The filter body is a ceramic substrate, on which a nano-inorganic film is arranged, the nano-inorganic film can allow liquid to pass through, and the thickness of the nano-inorganic film is 10 microns. The raw material components and weight ratio of the nano-inorganic thin film are: 15 parts of aluminum oxide, 10 parts of silicon oxide, 5 parts of titanium oxide, 3 parts of yttria-stabilized zirconia, 8 parts of titanium carbide, 3 parts of activated carbon fiber, 2 parts of magnesium, 8 parts of boron nitride.

[0036] The fingerprint scanning device includes an inorganic non-metallic coating arranged on the fingerprint, and the raw material type and weight ratio of the coating are: 60 parts of silicon oxide, 5 parts of boron oxide, 10 parts of potassium oxide, and 20 parts of barium oxide , 6 parts of zinc oxide, 5 parts of titanium oxide, 5 parts of aluminum oxide, and 3 parts of tungsten oxide.

Embodiment 3

[0038] The filter body is a ceramic substrate, on which a nano-inorganic film is arranged, the nano-inorganic film can allow liquid to pass through, and the thickness of the nano-inorganic film is 8 microns. The raw material components and weight ratio of the nano-inorganic thin film are: 12 parts of aluminum oxide, 6 parts of silicon oxide, 3 parts of titanium oxide, 2 parts of yttria-stabilized zirconia, 5 parts of titanium carbide, 2 parts of activated carbon fiber, 2 parts of magnesium, 7 parts of boron nitride.

[0039] The fingerprint scanning device includes an inorganic non-metallic coating arranged on the fingerprint, and the raw material type and weight ratio of the coating are: 57 parts of silicon oxide, 4 parts of boron oxide, 6 parts of potassium oxide, and 19 parts of barium oxide , 5 parts of zinc oxide, 2 parts of titanium oxide, 2 parts of aluminum oxide, and 2 parts of tungsten oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com