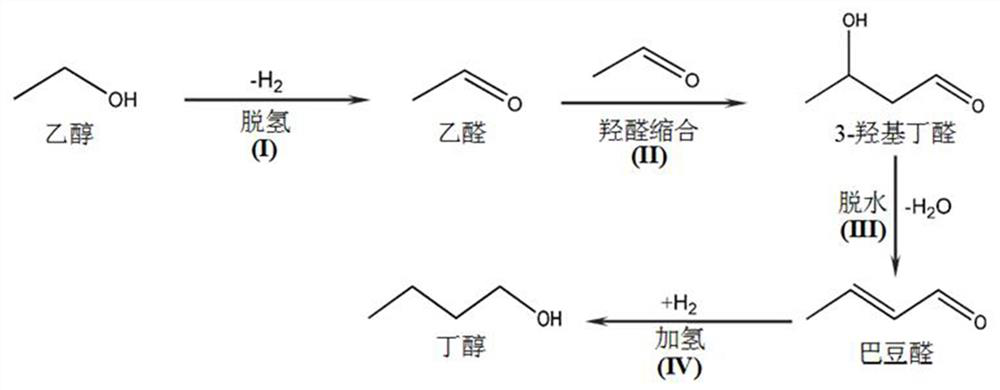

A nano-noble metal catalyst encapsulated by a metal-organic framework material and its preparation method and application

A metal-organic framework, precious metal catalyst technology, applied in the field of catalytic chemistry, can solve the problems of high reaction temperature, complex preparation, industrial application restrictions, etc., and achieve high activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

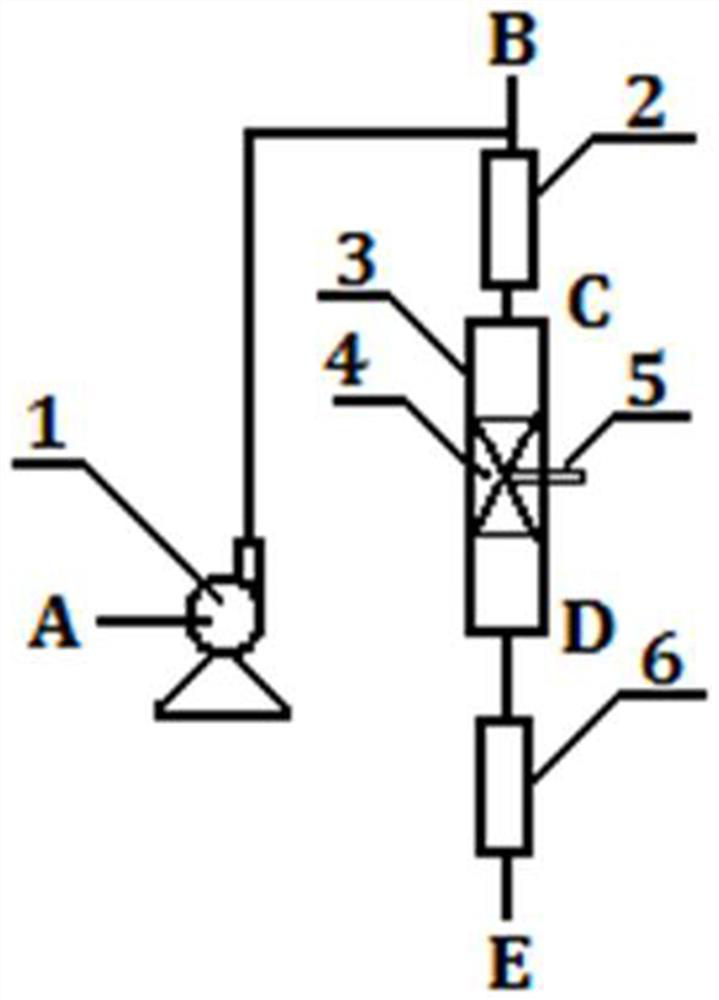

Method used

Image

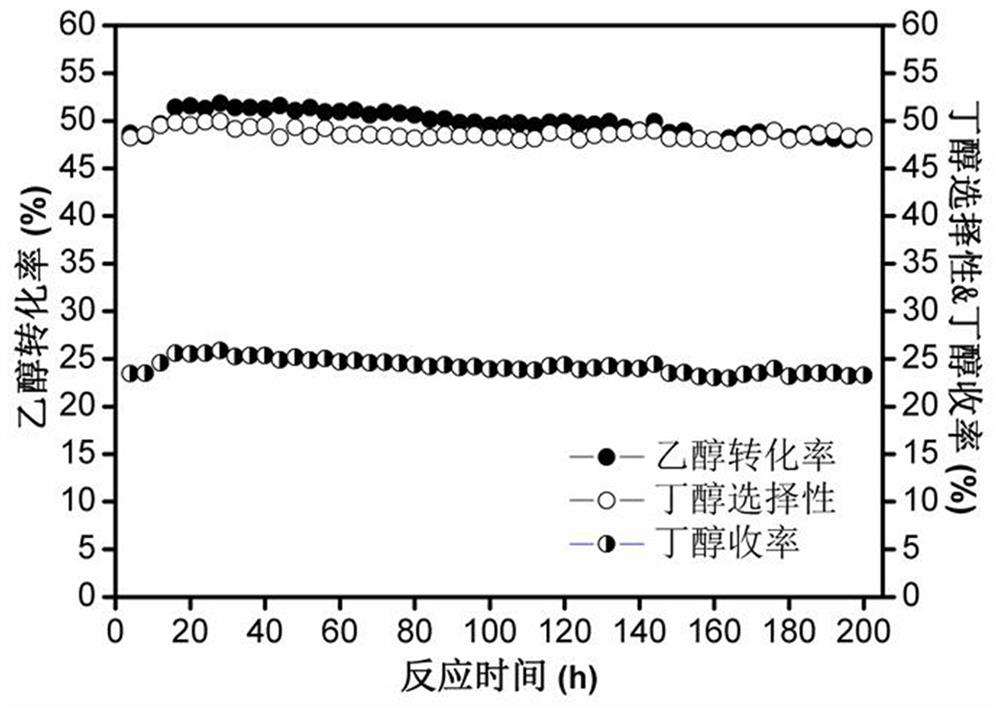

Examples

Embodiment 1

[0037] 0.0573g bis(acetylacetonate) palladium (Pd(acac) 2 ) was dissolved in a beaker containing 57.3mL of acetylacetone, stirred to dissolve, and then 1g of UiO-66 powder was added, and stirred at room temperature for 24h. Put the beaker containing the above mixture in an oil bath, stir and evaporate to dryness at 110°C, transfer the obtained solid powder to a blast drying oven at 150°C for 12 hours to remove the residual solvent in the channel, and obtain the 2wt after cooling %Pd@UiO-66 catalyst, denoted as catalyst A. The loading amount of metal Pd is 2wt%, and the rest is UiO-66 carrier.

Embodiment 2

[0039] The preparation method of catalyst B is the same as embodiment 1, but two (acetylacetonate) palladium (Pd (acac) 2 ) has a mass of 0.0143g. The weight content of metal Pd is 0.5wt%, and the rest is UiO-66 carrier.

Embodiment 3

[0041] The preparation method of catalyst C is the same as embodiment 1, but two (acetylacetonate) palladium (Pd (acac) 2 ) has a mass of 0.0287g. The weight content of metal Pd is 1wt%, and the rest is UiO-66 carrier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com