Tea Screening Device

A screening device and tea technology, which are applied in the directions of sieving, solid separation, tea treatment before extraction, etc., can solve the problems of large amount of feed, poor tea separation effect, uneven distribution of tea screening size, etc., to avoid Mixing, reducing the operation of artificial discharge, and the effect of high screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail through specific implementation methods:

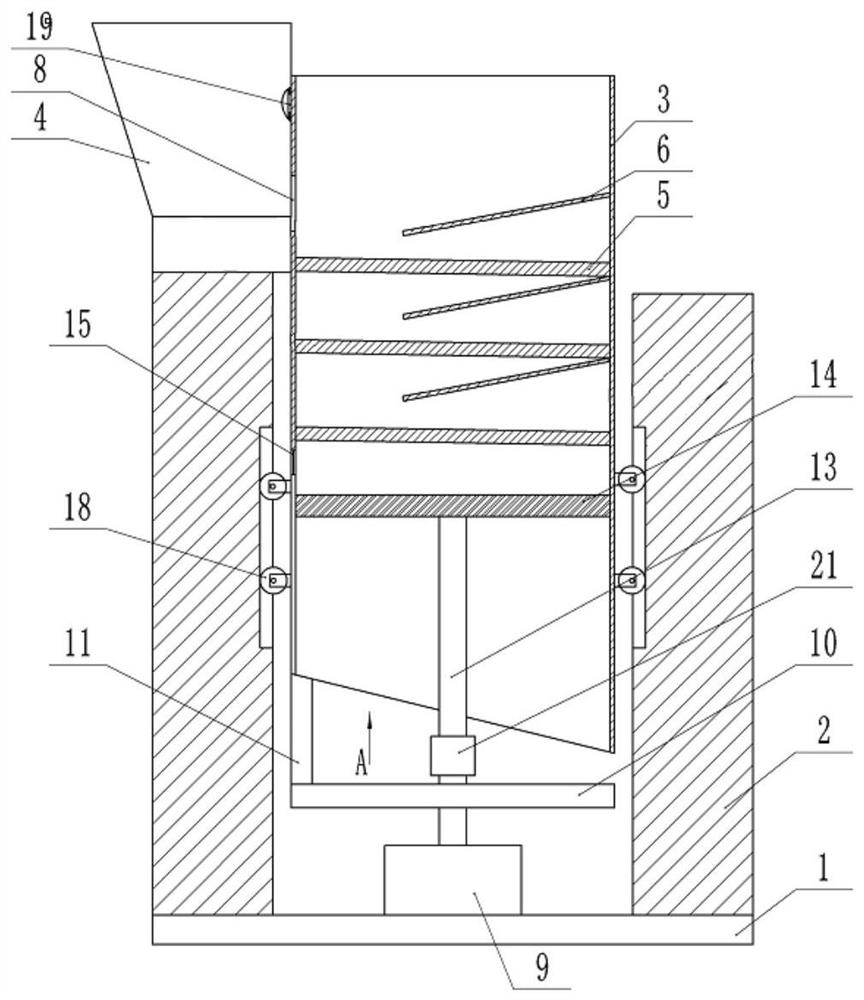

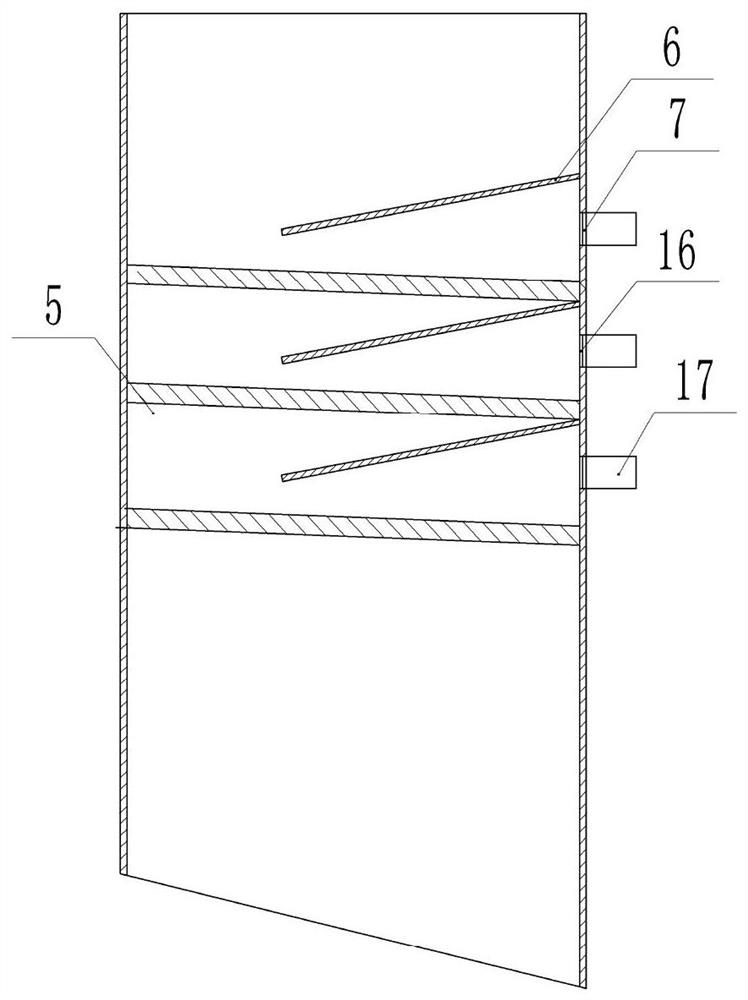

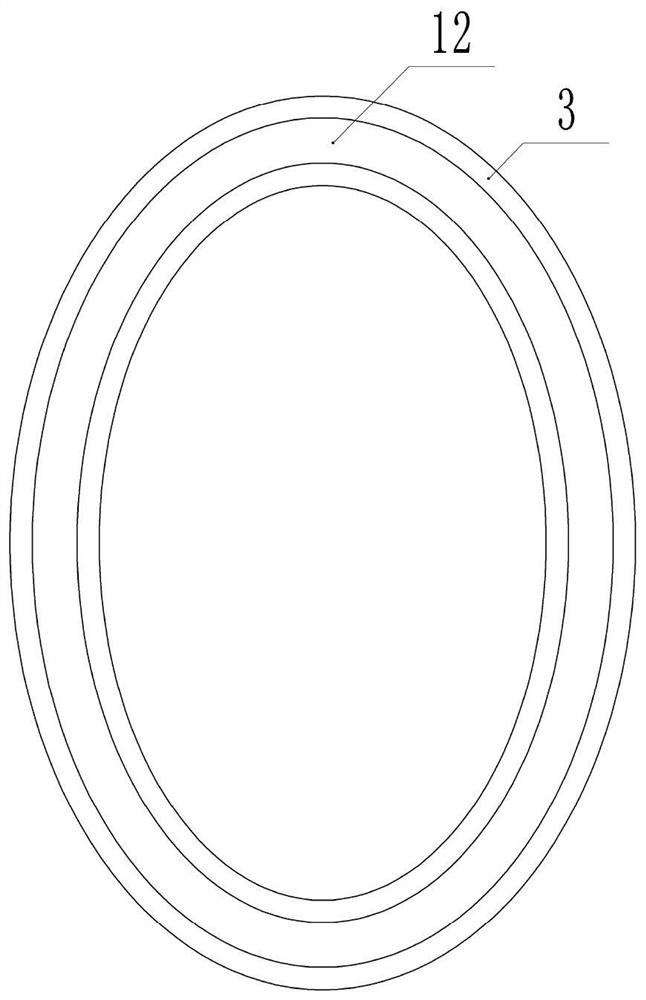

[0021] The reference signs in the drawings of the description include: base 1, bracket 2, sieve bucket 3, hopper 4, sieve plate 5, material guide plate 6, discharge port 7, feed port 8, motor 9, turntable 10, top Rod 11, chute 12, support rod 13, piston head 14, first one-way valve 15, second one-way valve 16, material guide pipe 17, roller 18, discharge port 19, bearing 21.

[0022] Such as figure 1 and figure 2 As shown, a tea screening device comprises a base 1, a support 2 is installed on the base 1, a slide rail is installed on the support 2, a screen bucket 3 is installed through a roller 18 in the slide rail, and the lower end surface of the screen bucket 3 is processed into slope, such as image 3 As shown, a chute 12 is provided on the inclined surface, a motor 9 with an output shaft arranged upward is installed in the middle of the base 1, a turntable 10 is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com