A jet cleaning method

A technology of jet flow and cleaning fluid, applied in metal processing equipment, manufacturing tools, abrasive feeding devices, etc., can solve the problems of troublesome on-site cleaning, high safety risks, endangering the health of operators, etc., to improve the safety of use and use. life, avoid pipeline blockage, and reduce cleaning energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

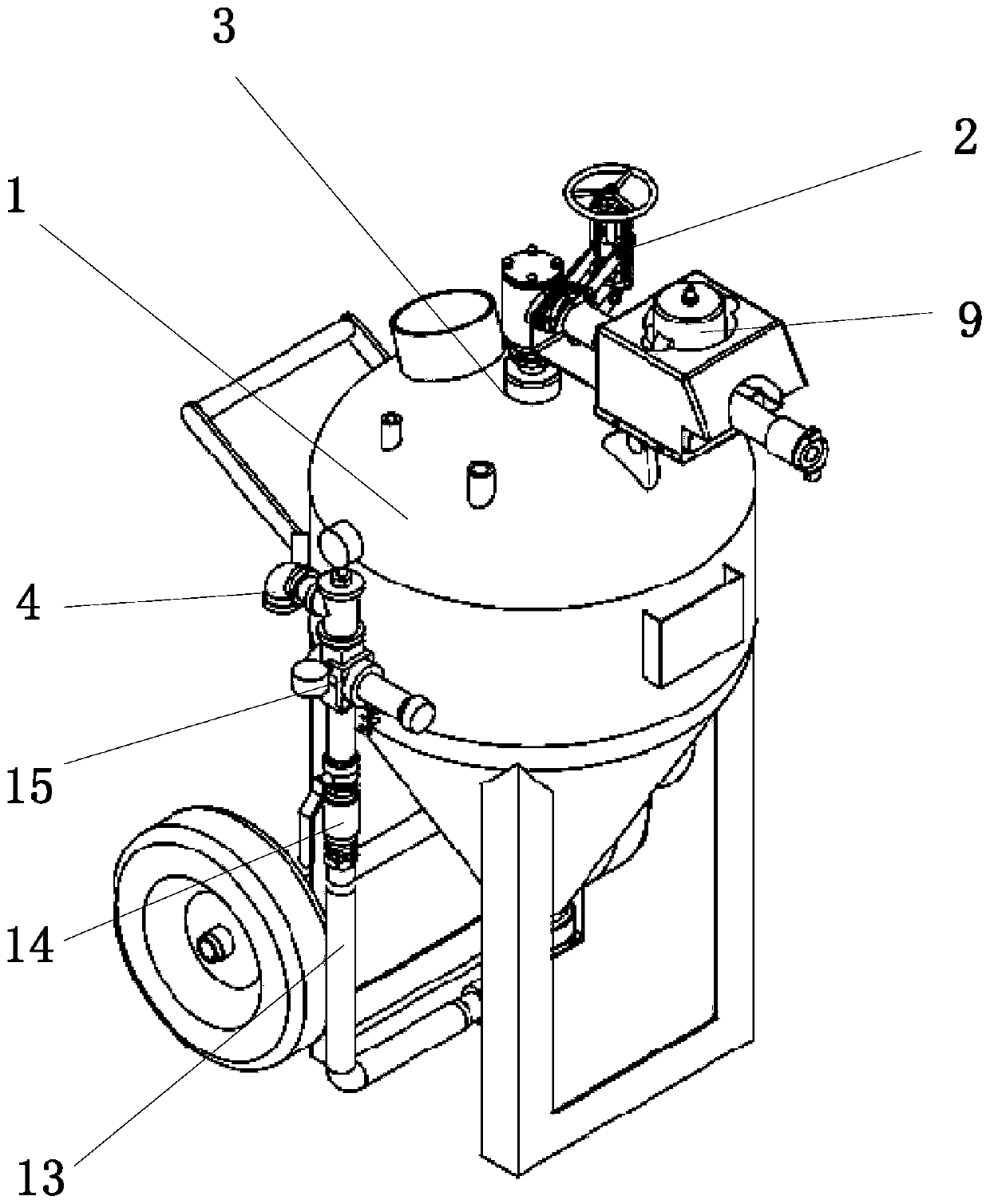

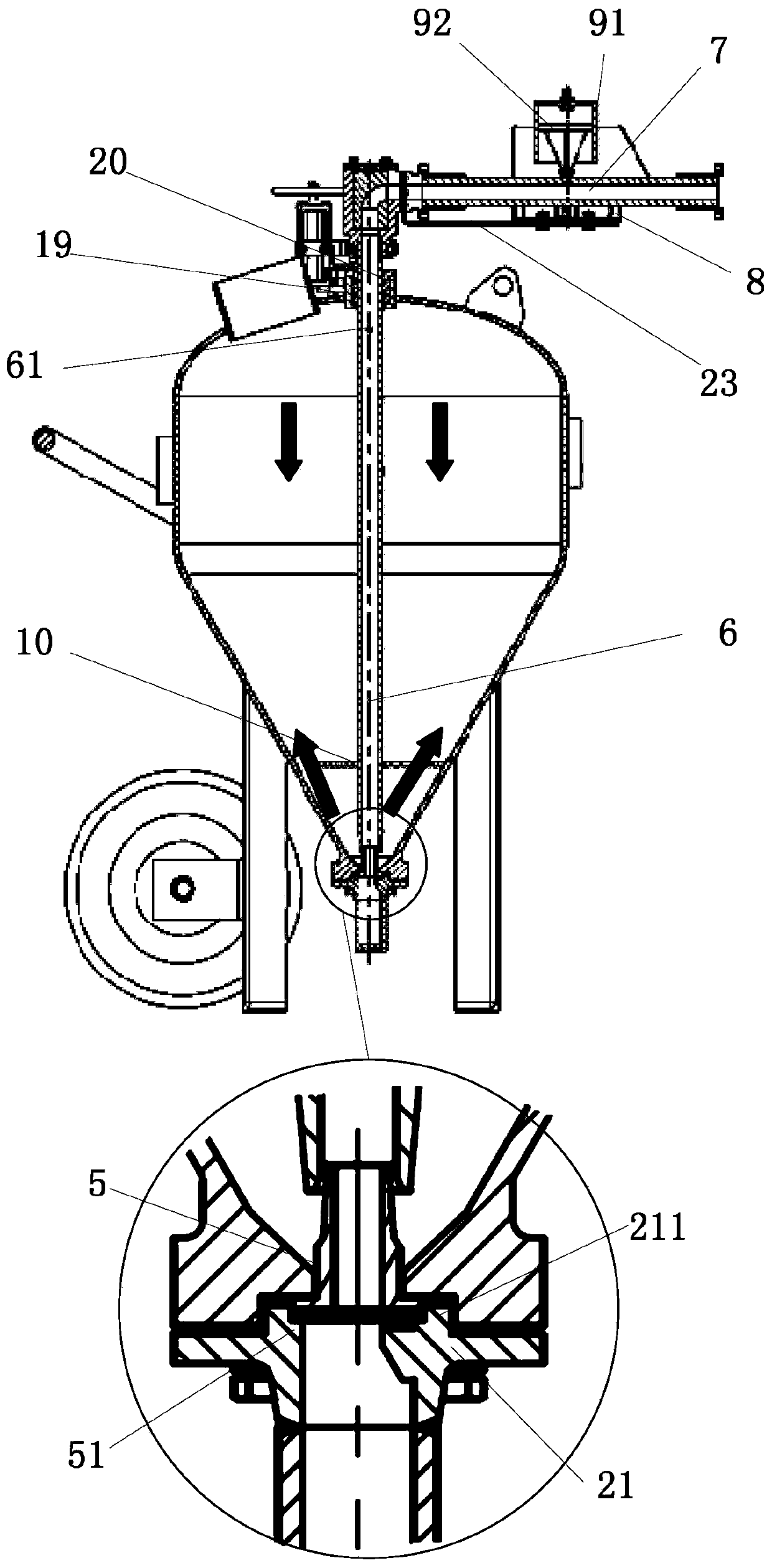

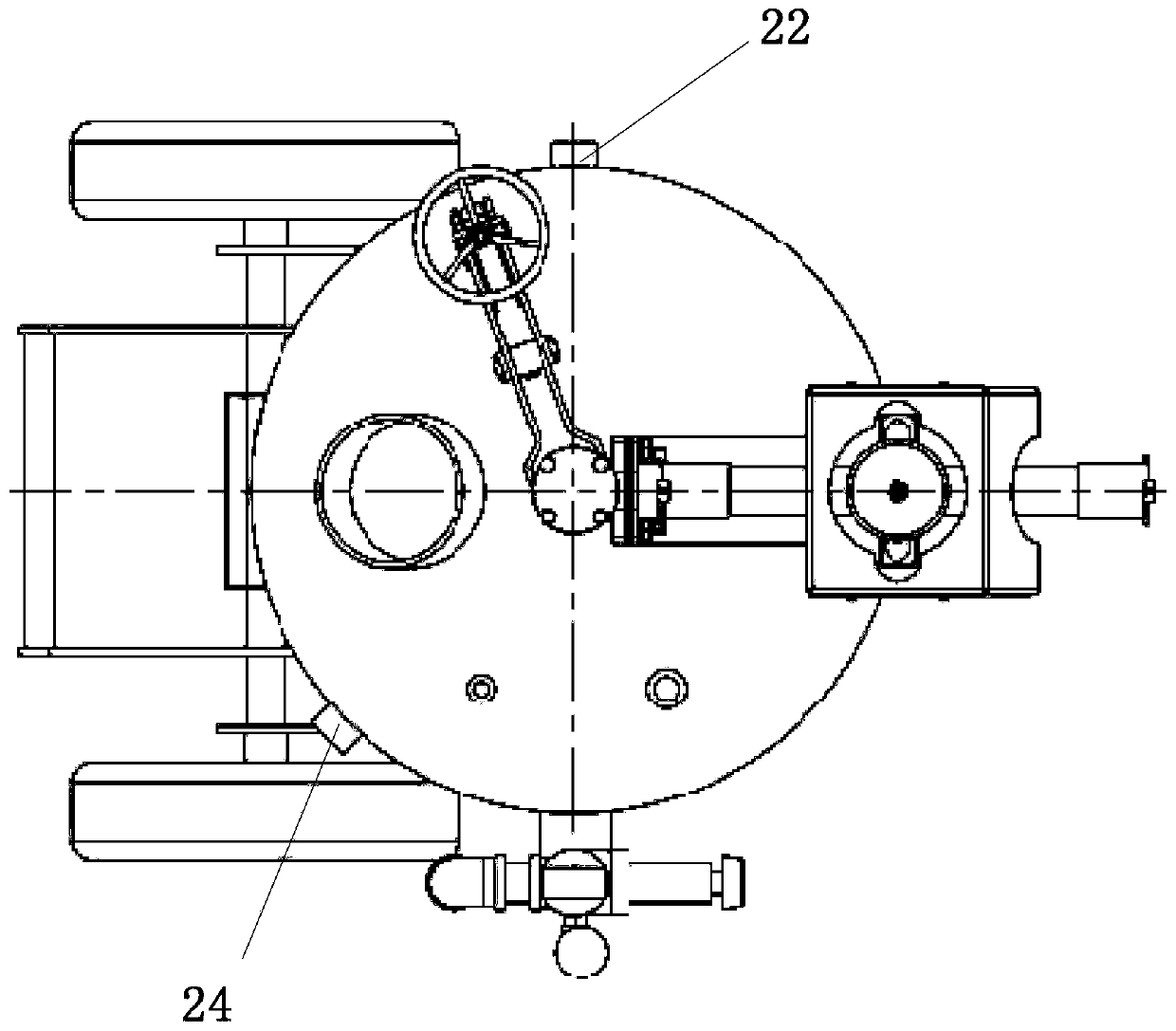

[0040] see figure 1 and 2, the embodiment of the present invention provides a jet cleaning equipment, including a tank 1, an accelerated jet component, a limit component 2 and an air source 4, the tank 1 is used to accommodate cleaning sand and cleaning liquid, and the top is provided with an installation hole 3. The accelerated jet assembly includes an air inlet nozzle 5 and a jet pipeline. The air inlet nozzle 5 is a hollow frustum structure and is arranged at the bottom of the tank body 1. The jet pipeline includes a main pipeline 6 and an outlet pipeline 7. The main pipeline 6 is a straight pipe, which is arranged in the tank body 1, and the lower end is closely matched with the air inlet nozzle 5, and the upper end protrudes out of the tank body 1 through the installation hole 3, and the outlet pipeline 7 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com