Dual-coded-disc encoder and servo joint using dual-coded-disc encoder

An encoder and double code technology, applied in the field of servo joints, can solve the problems of reducing the load capacity of joint belts, large joint volume and weight, and large number of joint parts, and achieve the effect of improving load capacity, compact structure and reducing volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

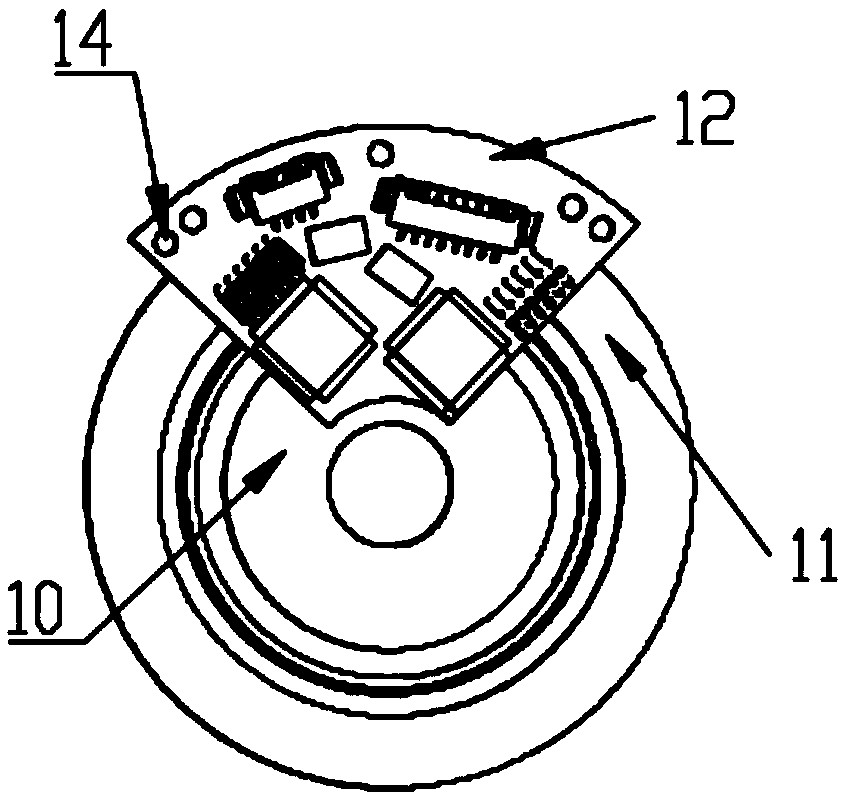

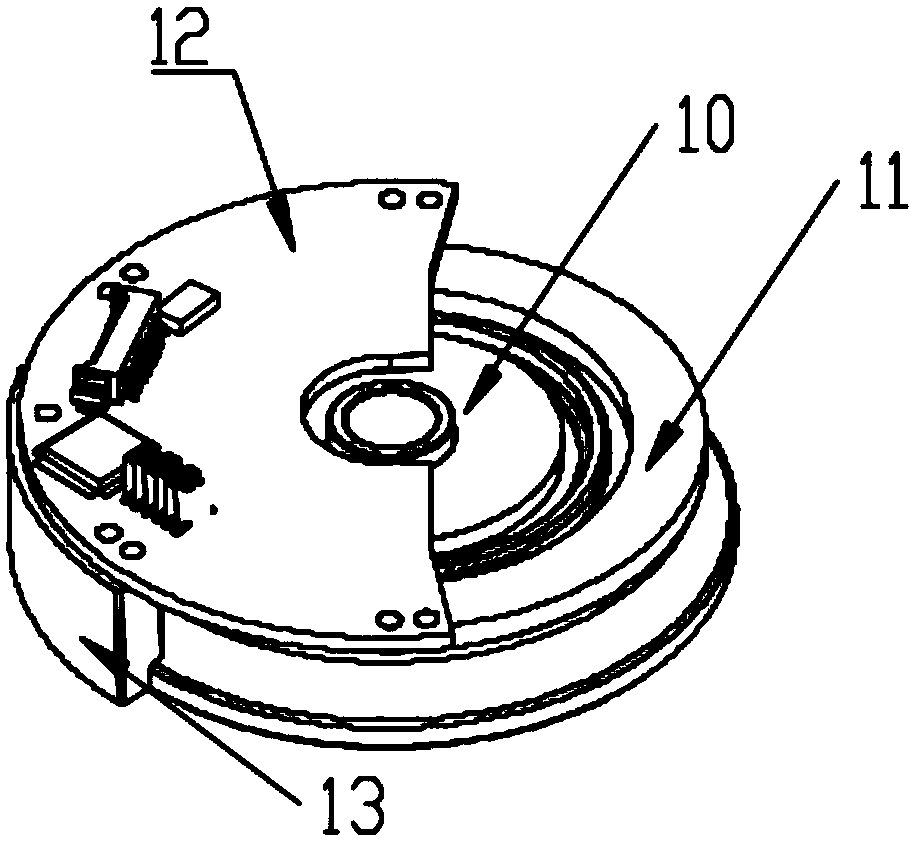

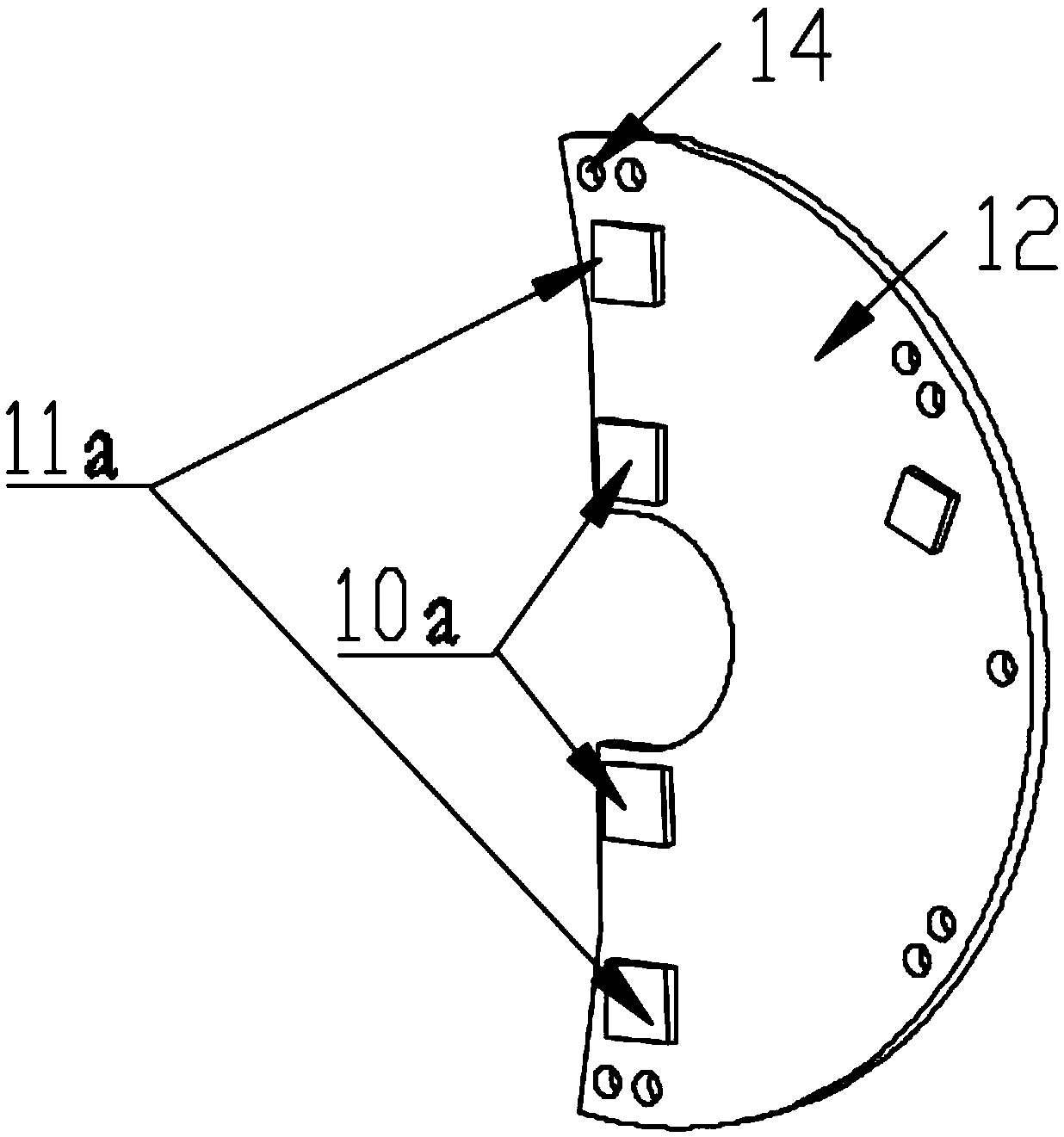

[0023] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

[0024] Such as Figure 1-5 As shown, the present invention provides a double code disc encoder 1, including a first code disc 10 for measuring the rotation angle of the reducer, a second code disc 11 for measuring the motor rotation angle, and a first reading head for reading And the second reading head, used to fix the circuit board 12 of the first reading head and the second reading head, wherein the first code wheel 10 and the second code wheel 11 are coaxial and nested on the same plane. The coaxial and horizontal nesting of the first code wheel 10 and the second code wheel 11 can reduce the number of parts and reduce the volume of the corresponding servo joint compared with the prior art where two encoders are arranged up and down.

[0025] Specifically, the first code disc 10 is used to measure the rotation angle of the reducer in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com