Spinning carrying robot

A technology for handling robots and transporters, which is applied in the direction of motor vehicles, transport objects, and article transport vehicles, etc., which can solve the problems of low work efficiency, long working hours, and long textile processes, etc., and achieve convenient handling of barrels, high work efficiency, and low labor costs. low intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further described below in conjunction with accompanying drawing:

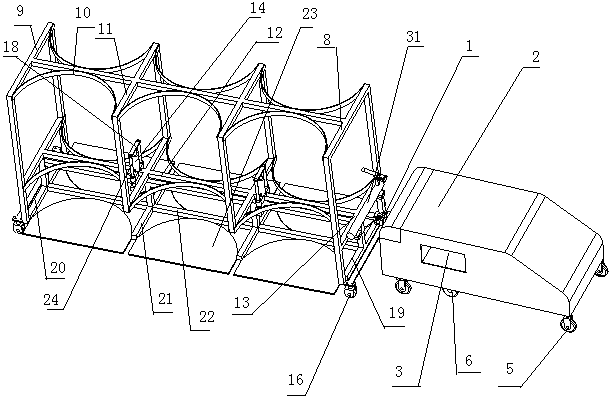

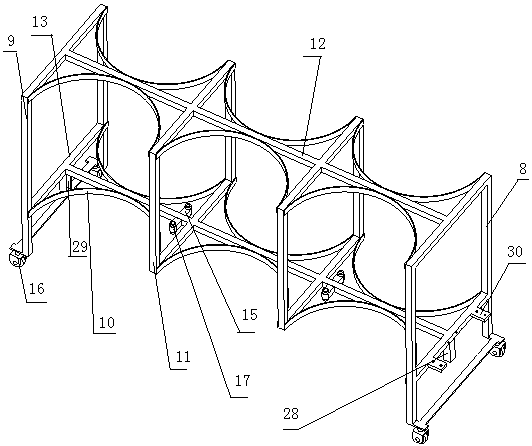

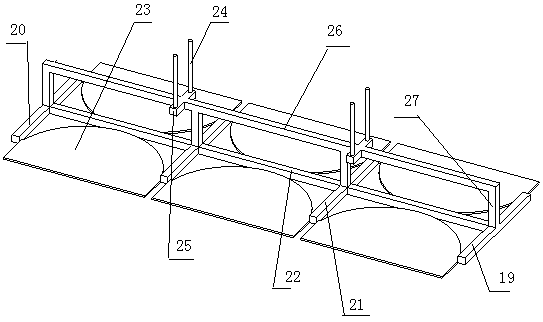

[0020]As shown in the accompanying drawings, a spinning handling robot includes a transport frame mechanism and a carrying trolley mechanism. 2 and a drive chassis assembly, the frame 2 is provided with a battery slot 3, and a battery is provided in the battery slot 3, and the drive chassis assembly is composed of a chassis 4, wheels 5, drive wheels 6 and a drive motor 7 , the four corners of the underframe 4 are respectively provided with wheels 5, the upper end of the wheels 5 is connected with the lower end of the underframe 4, the rear part of the underframe 4 is provided with a driving motor 7, and the driving motor 7 is connected to the The bottom frame 4 is connected, the output shaft of the drive motor 7 is connected with the drive wheel 6, the drive motor 7 is connected with the battery in the battery slot 3 through the wire, and the drive wheel 6 is driven to rotate by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com