Belt breaking capturing device

A catcher and belt breaking technology, which is applied to conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of many malfunctions, tearing and damage of the upper conveyor belt, and large amount of engineering, and achieve braking response. Fast, safe, high clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

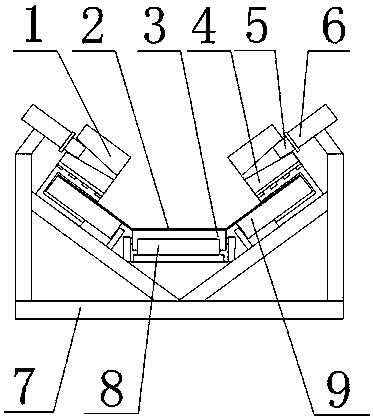

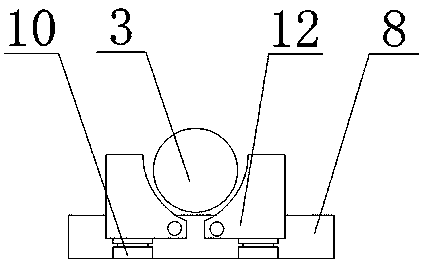

[0016] A broken tape catcher, comprising a bracket 7, a conveying roller 3 and a broken tape catching device 1, the conveying roller 3 is arranged on the support 7, a braking device 8 is arranged at the bottom of the conveying roller 3, and the braking device 8 is internally arranged There is a brake block 12, a hydraulic telescopic device 10 is arranged at the bottom of the brake block 12, side rollers 9 are arranged on both sides of the conveying roller 3, and a conveyor belt 2 is arranged on the conveying roller 3 and the side roller 9, and the broken belt catching device 1 is arranged on the side roller 9, and the broken tape catching device 1 is provided with a sliding wedge 4 inside, and the sliding wedge 4 is connected to the hydraulic rod 5, and the hydraulic rod 5 is connected to the hydraulic cylinder 6. An application method of a broken belt catcher is as follows: when the system detects that the conveyor belt 2 is broken, the brake device 8 is first activated, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com