A kind of ceramic ink-jet printing ink that promotes color development and preparation method thereof

A printing ink, ceramic inkjet technology, applied in inks, household appliances, applications, etc., can solve the problems of not enough black, reduced color performance, easy to block nozzles, etc., to improve whiteness, reduce inkjet volume, promote hair color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

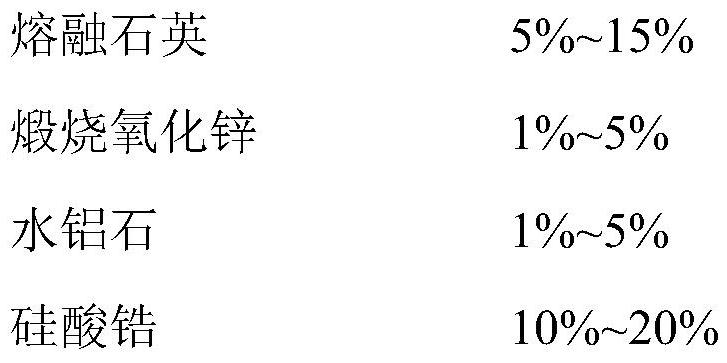

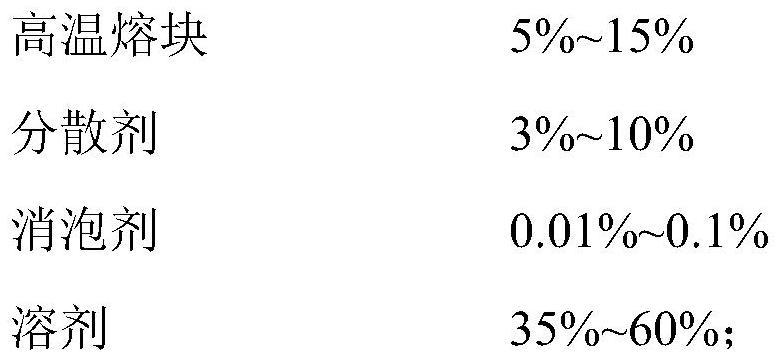

[0040] A ceramic inkjet printing ink that promotes color development, consisting of the following components by weight percentage:

[0041]

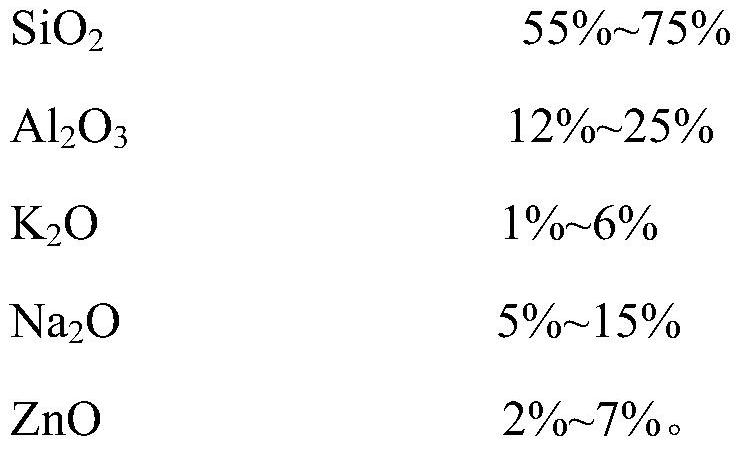

[0042] Wherein, the high-temperature frit is composed of the following components by weight percentage:

[0043]

[0044] Wherein, the dispersant is one or a combination of polyurethane dispersant or polymerized hydrogenated ricinoleic acid.

[0045] Wherein, the defoamer is one of BYK-055, BYK-028 or BYK-052 or a combination of any two or more.

[0046] Wherein, the solvent is one or a combination of two or more of mineral oil, isopropyl laurate, methyl oleate, isooctyl cocoate or lauryl alcohol.

[0047] The preparation method of the above-mentioned a kind of ceramic ink-jet printing ink that promotes hair color, it comprises the following steps:

[0048] Step A, raw material grinding: Grinding the fused silica, calcined zinc oxide, diaspore, zirconium silicate and high-temperature frit in the formula respectively to obtain fus...

Embodiment 2

[0053] A ceramic inkjet printing ink that promotes color development, consisting of the following components by weight percentage:

[0054]

[0055]

[0056] Wherein, the high-temperature frit is composed of the following components by weight percentage:

[0057]

[0058] In this embodiment, the dispersant is polymerized hydrogenated ricinoleic acid.

[0059] In this example, the defoamer is BYK-028.

[0060] In this embodiment, the solvent is a composition of isopropyl laurate and methyl oleate.

[0061] The preparation method of the above-mentioned a kind of ceramic ink-jet printing ink that promotes hair color, it comprises the following steps:

[0062] Step A, raw material grinding: Grind the fused silica, calcined zinc oxide, gibbsite, zirconium silicate and high-temperature frit to 3000 mesh respectively to obtain fused silica powder, calcined zinc oxide powder, hydrated aluminum Stone powder, zirconium silicate powder and high temperature frit powder;

[00...

Embodiment 3

[0068] A ceramic inkjet printing ink that promotes color development, consisting of the following components by weight percentage:

[0069]

[0070] Wherein, the high-temperature frit is composed of the following components by weight percentage:

[0071]

[0072] In this embodiment, the dispersant is polymerized hydrogenated ricinoleic acid.

[0073] In this example, the defoamer is BYK-028.

[0074] In this embodiment, the solvent is a composition of isopropyl laurate and methyl oleate.

[0075] The preparation method of the above-mentioned a kind of ceramic ink-jet printing ink that promotes hair color, it comprises the following steps:

[0076] Step A, raw material grinding: Grind the fused silica, calcined zinc oxide, diaspore, zirconium silicate and high-temperature frit to 2500 mesh respectively to obtain fused silica powder, calcined zinc oxide powder, hydrated aluminum Stone powder, zirconium silicate powder and high temperature frit powder;

[0077] Step B, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com