A method for discharging harmful elements of blast furnace and cleaning blast furnace type

A technology of harmful elements and blast furnace type, which is applied in blast furnace smelting treatment, discharges harmful elements of blast furnace and cleans up blast furnace furnace type, can solve the problems of not being very good and limited blast furnace operation system, so as to improve safety and reduce labor intensity. , the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

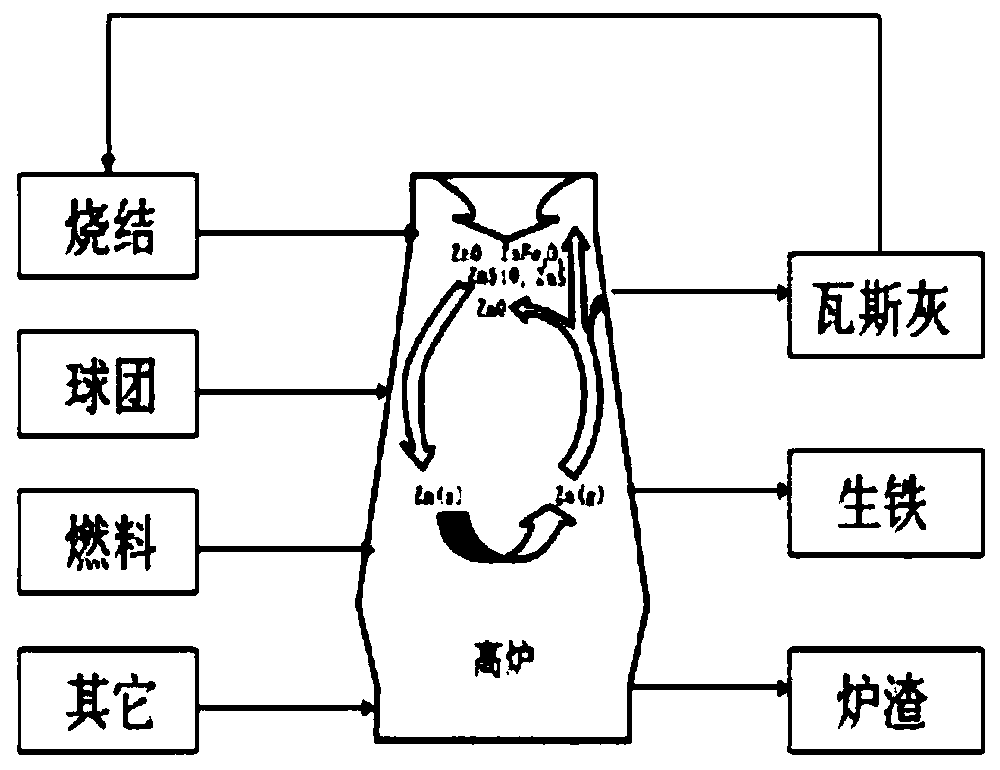

[0096] A certain 2200m 3 The blast furnace has been put into operation for 3 years after its renovation and maintenance. Alkali metal K, Na and light metal Zn are continuously circulating and accumulating in the blast furnace, occupying the effective space of the blast furnace, diluting the effective concentration of gas, and catalyzing the coke gasification reaction. And cause nodules on the blast furnace body, make the blast furnace shape irregular, affect the stability of the blast furnace and energy saving and consumption reduction. The stable operation of the blast furnace was greatly damaged, the intensity of manual labor increased sharply, the level of energy consumption rose sharply, and the abnormality of the blast furnace was caused. Therefore, "a method of discharging harmful elements from the blast furnace and cleaning the blast furnace type" was adopted.

[0097] Step 1: Prepare for empty material

[0098] 1) Appropriately reduce the amount of coke in the center ...

Embodiment 2

[0121] A certain 3200m 3 The blast furnace has been put into operation for 4 years after the renovation and maintenance. The alkali metal K, Na and light metal Zn are continuously circulating and accumulating in the blast furnace, occupying the effective space of the blast furnace, diluting the effective concentration of the gas, and catalyzing the coke gasification reaction. And cause nodules on the blast furnace body, make the blast furnace shape irregular, affect the stability of the blast furnace and energy saving and consumption reduction. The stable operation of the blast furnace was greatly damaged, the intensity of manual labor increased sharply, the level of energy consumption rose sharply, and the abnormality of the blast furnace was caused. Therefore, "a method of discharging harmful elements from the blast furnace and cleaning the type of the blast furnace" was adopted.

[0122] Step 1: Prepare for empty material

[0123] 1) Appropriately reduce the amount of coke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com