Tin dioxide/zirconium oxide doped carbon composite material for lithium ion battery, preparation method and application thereof

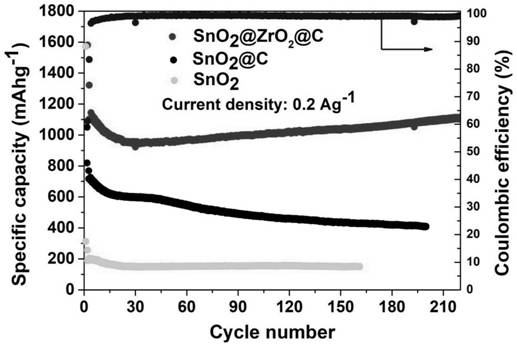

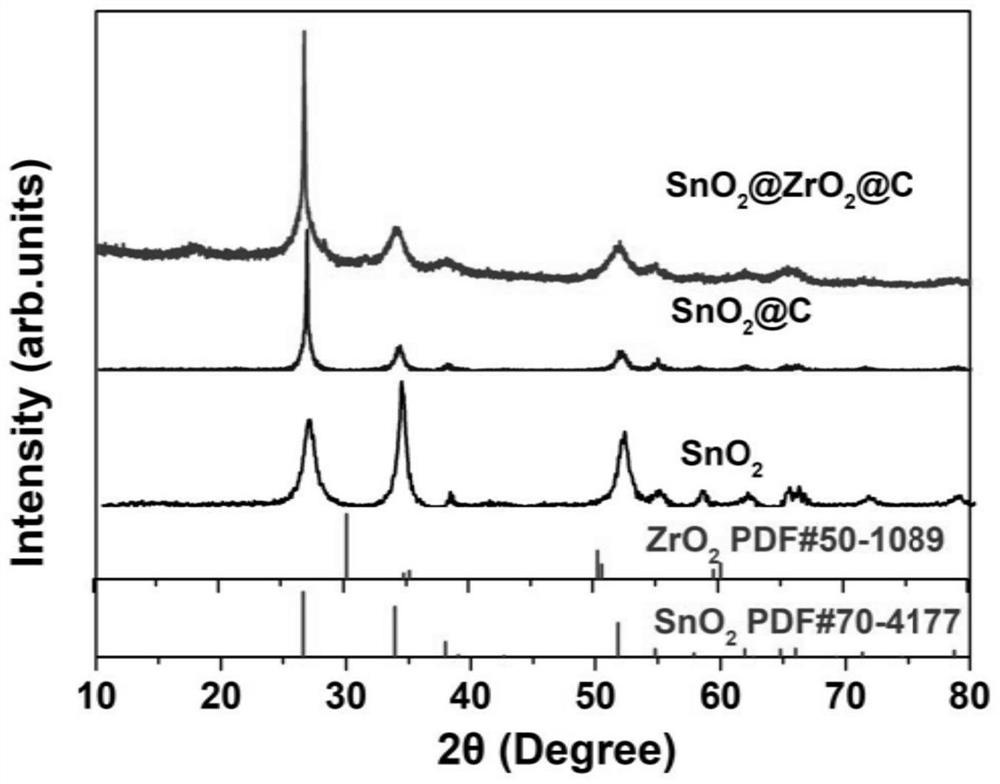

A carbon composite material, tin dioxide technology, applied in the field of electrochemistry, can solve the problems of poor cycle stability, volume expansion, Coulomb efficiency and rate performance, and achieve the effects of low cost, difficult capacity and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

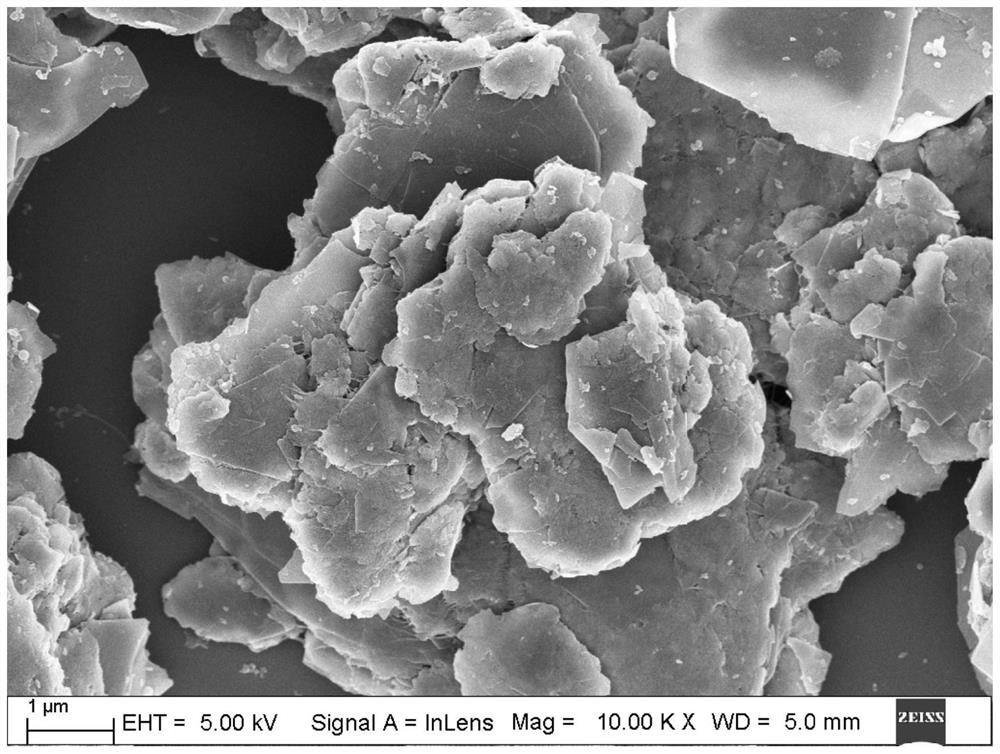

[0039] This embodiment provides a tin dioxide / mercuric oxide doped carbon composite material, the specific preparation steps are as follows:

[0040] S1. Put 0.7g (0.0046mol) tin dioxide and 0.05g (0.0004mol) zirconia into a ball mill jar and carry out 30min intermittent ball milling for 30h to obtain a tin dioxide / zirconia composite material;

[0041] S2. Continue to add 0.25g (0.0208mol) acetylene black to continue ball milling, and continue ball milling for 5h to obtain tin dioxide / zirconia doped carbon composite material, denoted as SnO 2 @ZrO 2 @C.

Embodiment 2

[0043] This embodiment provides a tin dioxide / zirconia doped carbon composite material, the specific preparation steps are as follows:

[0044]S1. After putting 0.7g (0.0046mol) carbon black and 0.03g (0.0002mol) zirconia into a ball mill jar and carrying out 30min intermittent ball milling for 24h, a tin dioxide / zirconia composite material is obtained;

[0045] S2. Continue to add 0.25g (0.0208mol) citric acid to continue ball milling, and continue ball milling for 10h to obtain a tin dioxide / zirconia doped carbon composite material, which is denoted as SnO 2 @ZrO 2 @C.

Embodiment 3

[0047] This embodiment provides a tin dioxide / zirconia doped carbon composite material, the specific preparation steps are as follows:

[0048] S1. After putting 0.7g (0.0046mol) carbon black and 0.05g (0.0004mol) zirconia into a ball mill jar and carrying out 30min intermittent ball milling for 48h, a tin dioxide / zirconia composite material is obtained;

[0049] S2. Continue to add 0.7g (0.0583mol) acetylene black to continue ball milling, and continue ball milling for 4h to obtain a tin dioxide / zirconia doped carbon composite material, which is denoted as SnO 2 @ZrO 2 @C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com