6063 aluminum alloy and processing technique thereof

A processing technology and aluminum alloy technology, which is applied in the field of aluminum alloy, can solve the problems of retention and rare earth application research, and achieve the effect of improving comprehensive mechanical properties and improving hot extrusion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

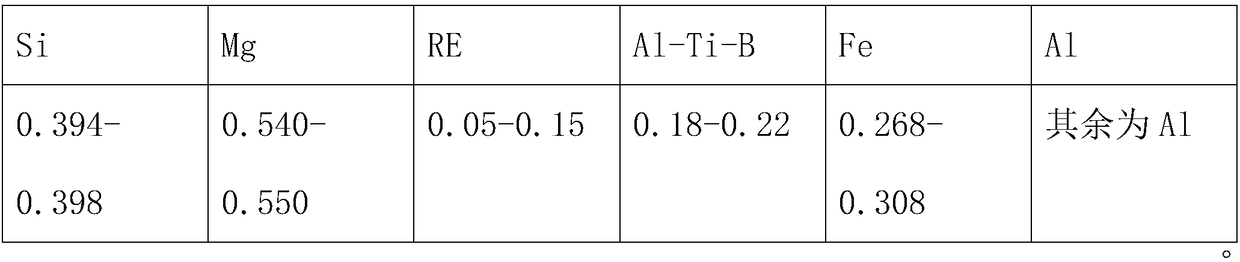

[0018] A 6063 aluminum alloy, comprising the following mass fraction ratio raw materials:

[0019]

Embodiment 2

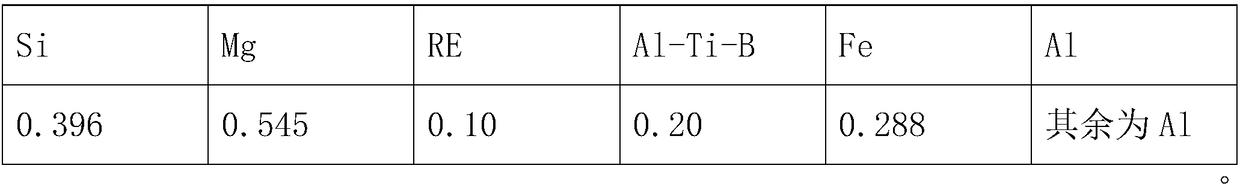

[0021] A 6063 aluminum alloy, comprising the following mass fraction ratio raw materials:

[0022] Si

Embodiment 3

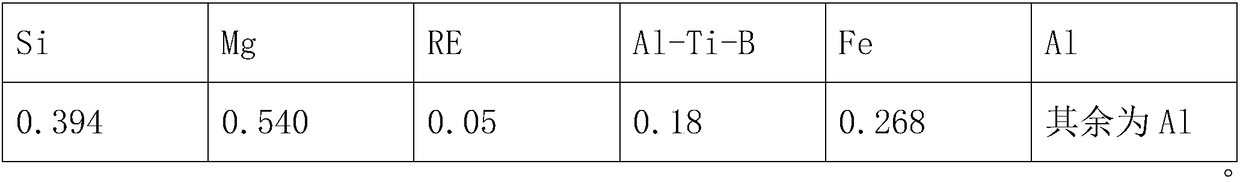

[0024] A 6063 aluminum alloy, comprising the following mass fraction ratio raw materials:

[0025] Si

Mg

RE

Al-Ti-B

Fe

Al

0.396

0.545

0.10

0.20

0.288

The rest is Al

[0026] The invention also discloses a processing technology of 6063 aluminum alloy, comprising the following steps:

[0027] (1) Put aluminum ingots and Al-Si master alloys into the furnace according to the composition design requirements, and add magnesium ingots, Al-rare earth master alloys, and Al-Ti-B in turn after they are melted;

[0028] (2) After degassing, refining, stirring, slag removal and other processes, cast a 100mm×4000mm cast rod at 730°C by semi-continuous water-cooled casting method;

[0029] (3) Cut it into an ingot of 100mm×390mm, and homogenize the ingot at 560°C for 6h;

[0030] (4) Finally, use a 6MN extruder to hot-extrude the profile.

[0031] As one of the preferred modes of the present invention, the furnace used in the step (1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com