Anti-silt turbulent vane guide wheel and turbulent pump based on the turbulent vane guide wheel

A turbulent flow and guide wheel technology, applied in the field of turbulent flow pumps, can solve the problems of insufficient production binding capacity of electric pump design manufacturers, difficulty in the design of the vane guide wheel to meet the use requirements, and increase the rotational resistance of the vane guide wheel bearings, etc., to achieve stability and high efficiency Oil production, reduce the probability of plugging, and increase the effect of mud and sand activities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

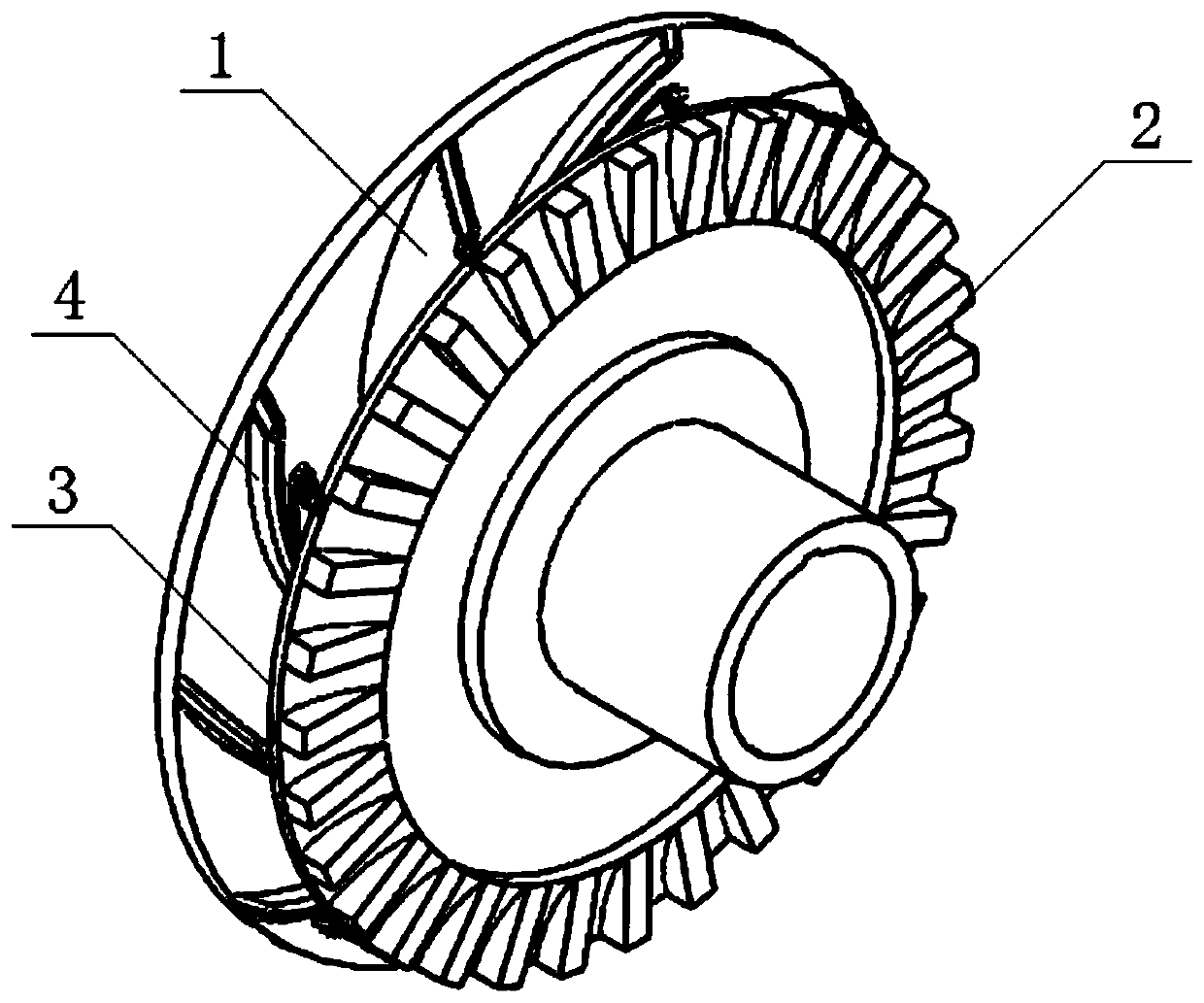

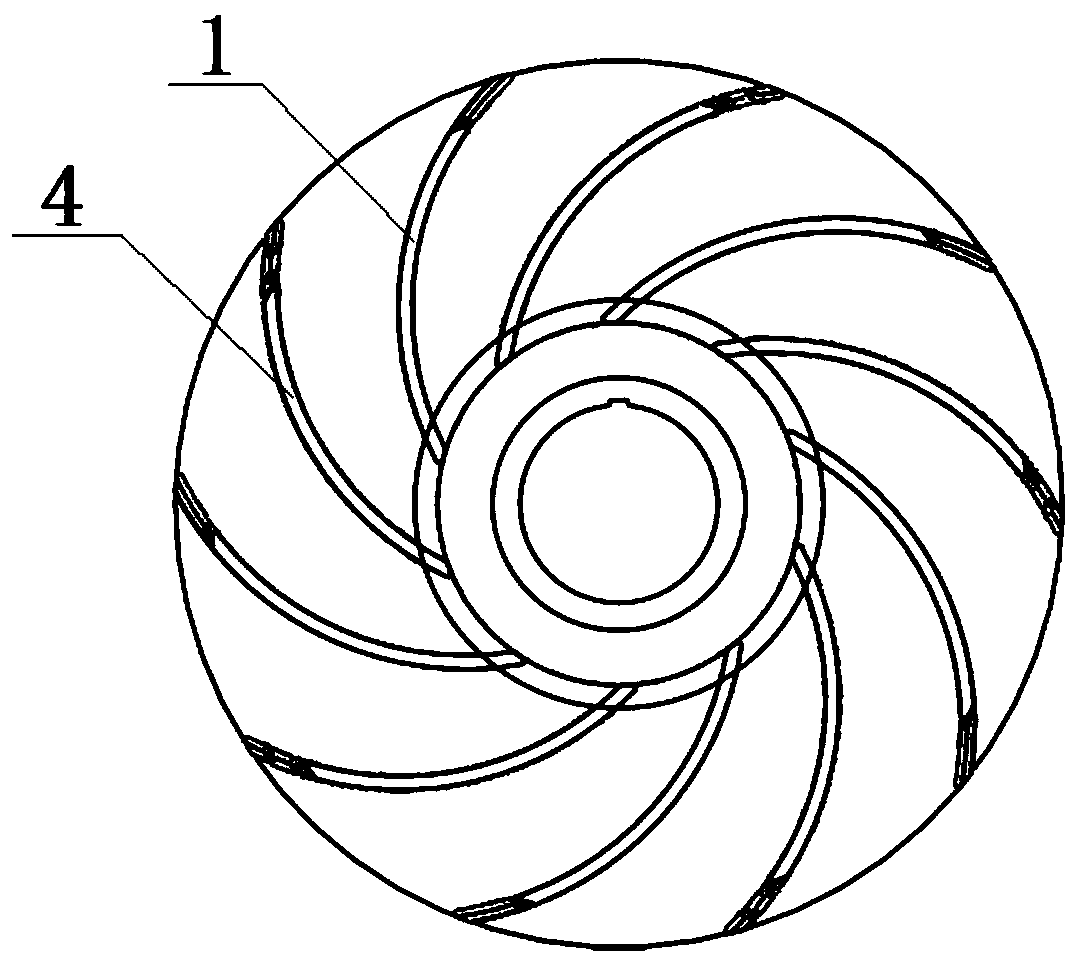

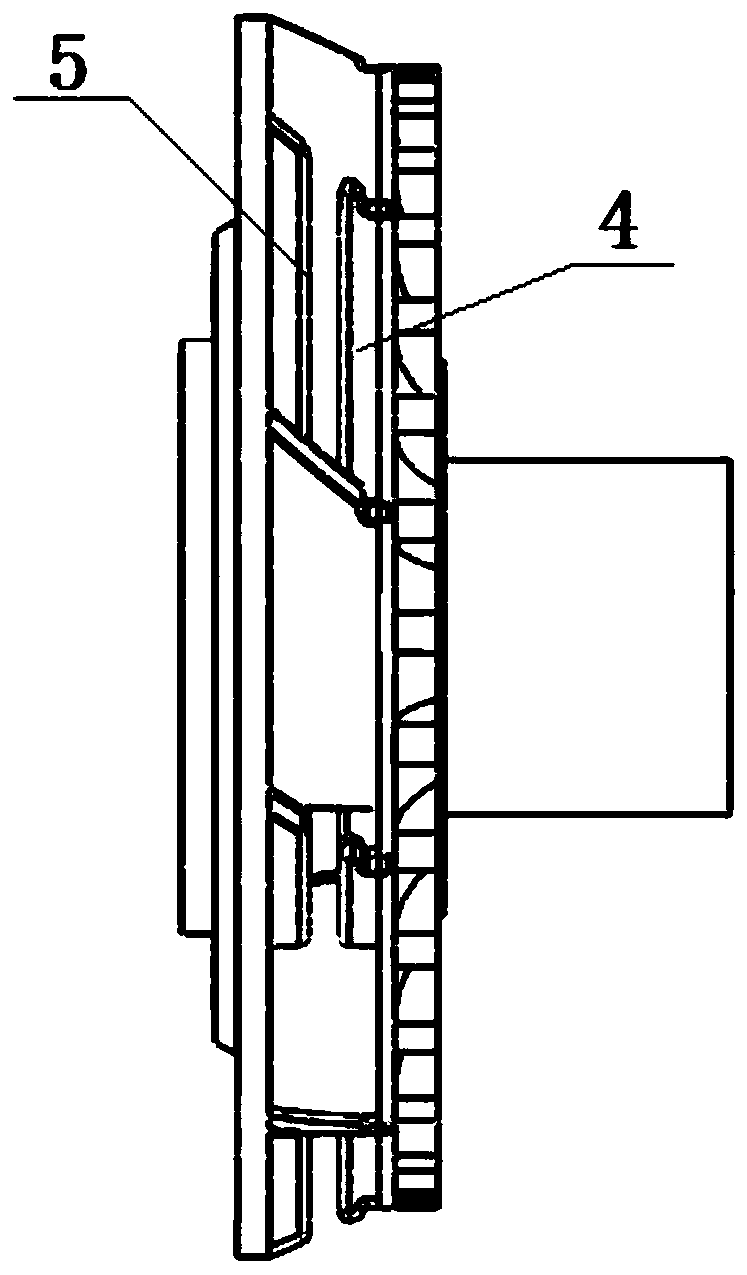

[0025] like Figure 1 to Figure 6 As shown, this embodiment provides a mud-sand turbulent-flow vane guide wheel, which is assembled by a single-stage impeller 6 and a single-stage guide casing 7. The single-stage impeller 6 is innovatively designed as a turbulent impeller on the basis of a conventional centrifugal impeller, and the turbulent flow The outer diameter of the impeller is the same as that of the conventional impeller with the same displacement. The turbulent impeller rotates inside the single-stage guide housing 7 to form a single-stage turbulent vane guide wheel. The single-stage turbulent vane guide wheels are respectively installed at the outlet 8 of the single-section pump and the inlet 9 of the single-section pump to form a turbulent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com