Tool for measuring assembly size of finished part

A technology for assembling dimensions and measuring tooling, which is applied in the field of measurement, can solve problems such as the inability to use depth gauges for direct measurement, high requirements for measurement accuracy, and low measurement efficiency, so as to improve labor efficiency and reliability of measurement results, improve assembly efficiency, and avoid The effect of the entry of excess

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Hereinafter, the present invention will be further described in conjunction with the drawings and specific embodiments.

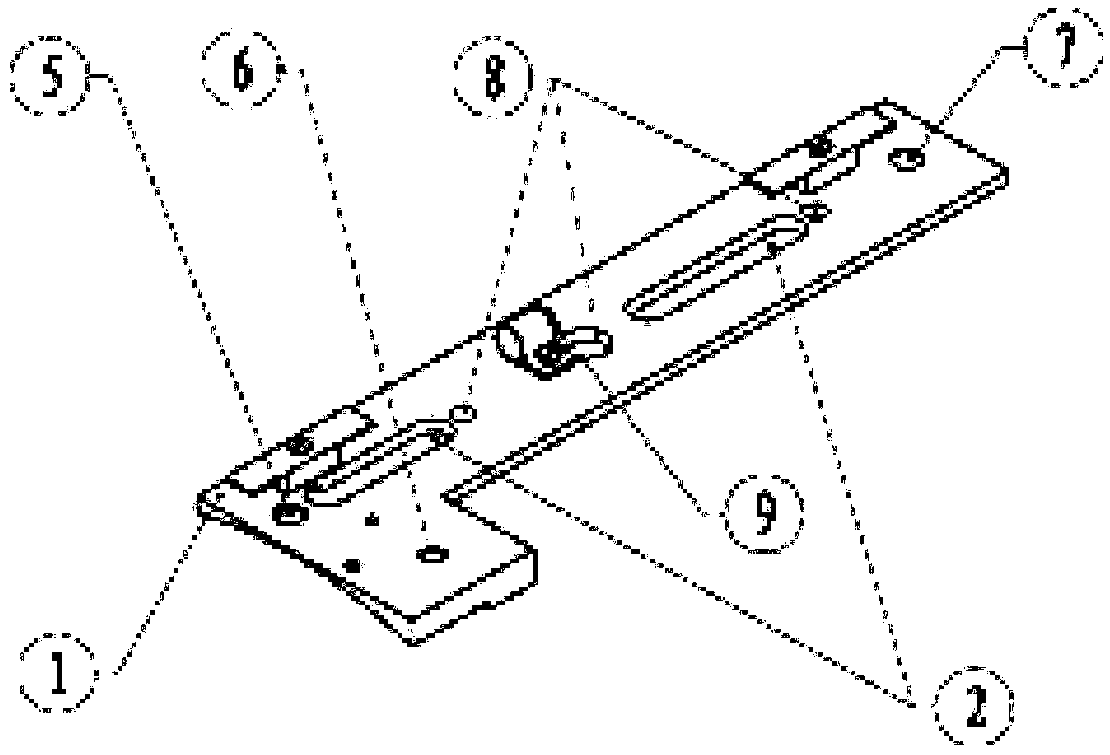

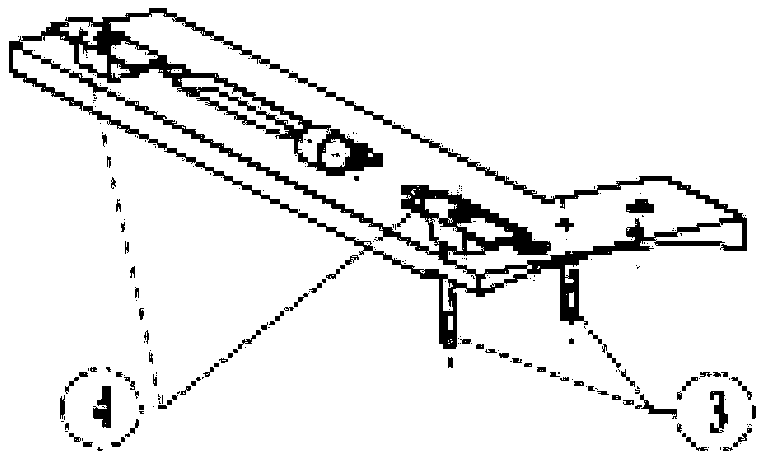

[0014] Such as figure 1 , 2 As shown, in this embodiment, it is a kind of assembly size measuring tool, which includes: a measuring base 1, a positioning glass plate 2 embedded in the measuring base, a positioning pin 3 installed on the measuring base, The self-inspection board 4 installed on the measurement base is distributed with measurement holes 5, 6, 7, observation holes 8, and sample columns 9.

[0015] The measurement base 1 is L-shaped, the bottom surface is a curved surface, and the radian is the same as that of the cabin body, which can ensure that the measurement base 1 fits the cabin body when it is placed on the outer surface of the cabin. The top surface of the measurement base 1 is a plane, and the The horizontal plane where the measurement reference point on the body is located moves in parallel, and the top surface remains in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com