Vibration test device

A testing device and vibration table technology, which is used in measurement devices, vibration testing, and testing of machine/structural components, etc., can solve the problems of large size of seismic testing instruments, unsuitable measuring instruments, and complex structures, and achieve adjustable vibration intensity. , the effect of shortened life and strong safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

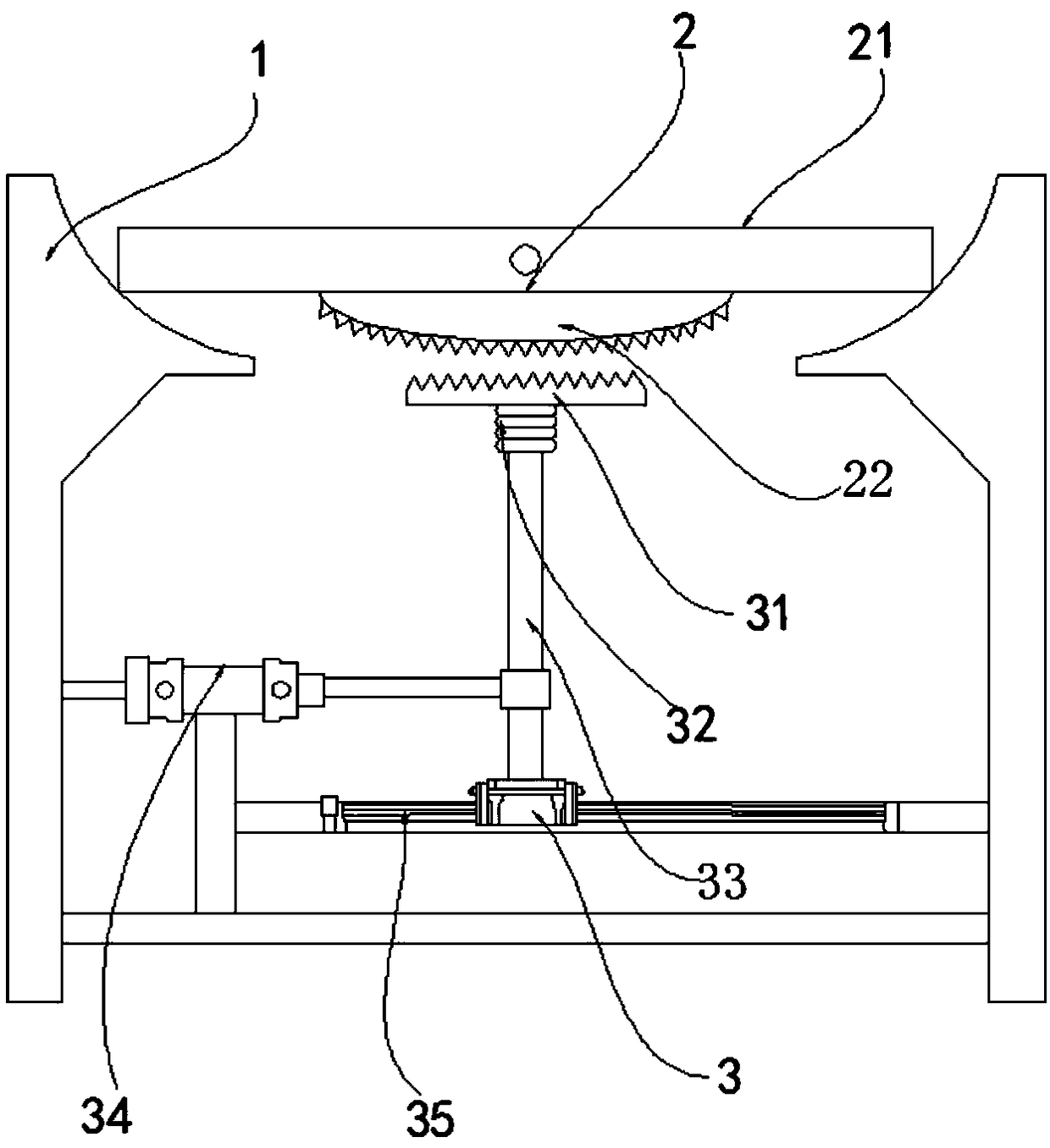

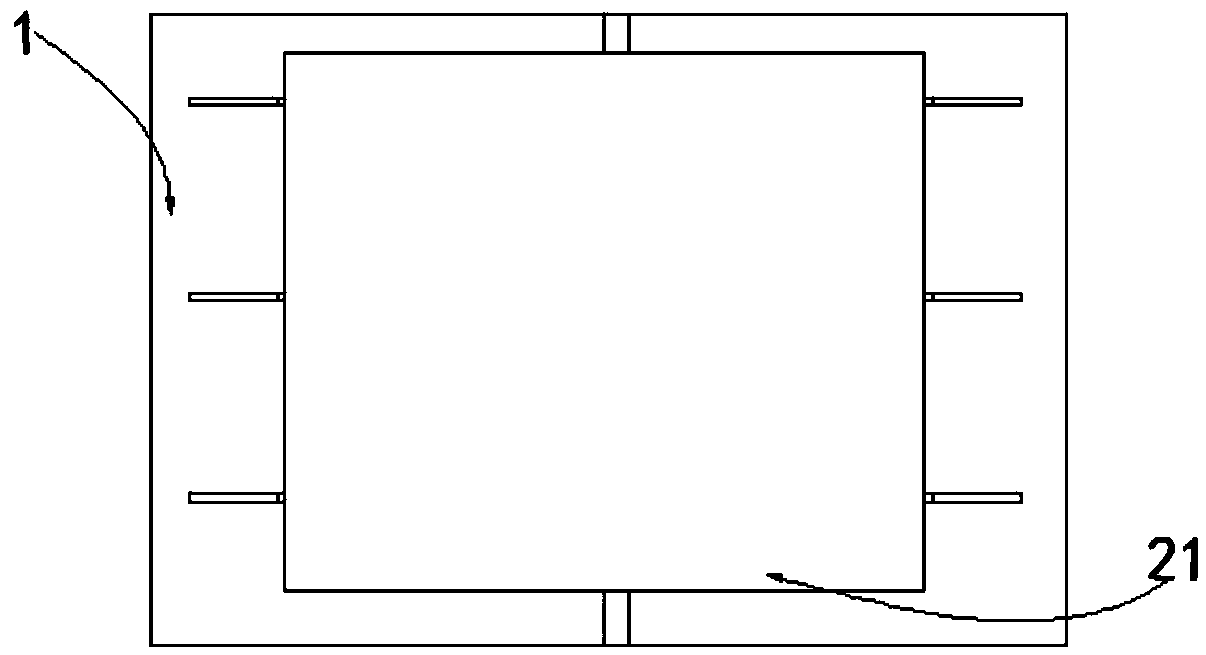

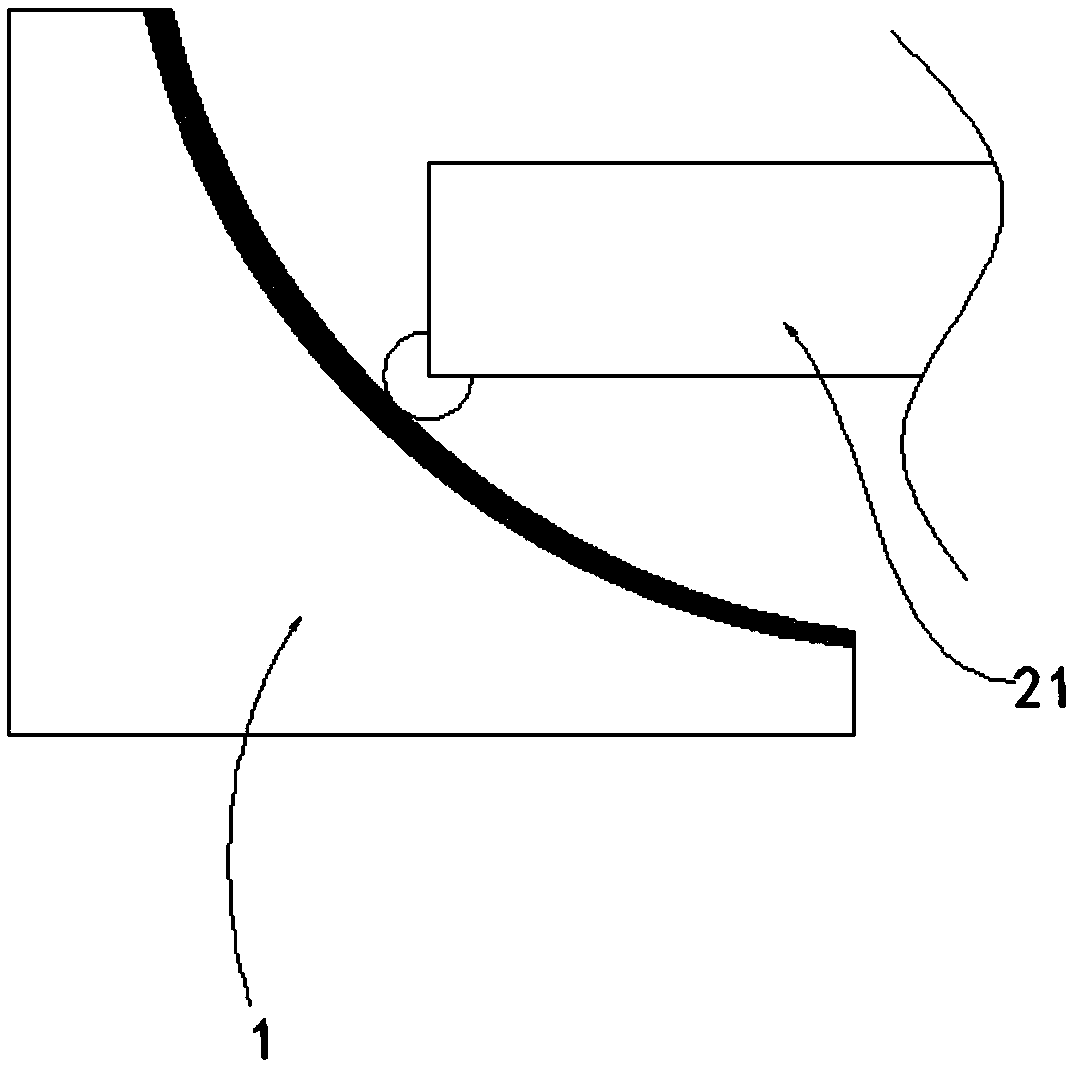

[0021] A vibration testing device, comprising a frame 1, a passive mechanism 2, and an active mechanism 3, the passive mechanism 2 is placed on the upper end of the frame 1, the passive mechanism 2 is connected to the lower end of the frame 1, and the active mechanism 3 is connected to the passive mechanism 3. The bottom of mechanism 2 cooperates by gear; Described driving mechanism 3 comprises spur rack 31, multi-layer damping ring 32, vertical bar 33, pushes cylinder 34 and slide bar 35, and the lower surface of described spur rack 31 is provided with multiple Layer shock absorbing ring 32, described multilayer shock absorbing ring 32 is positioned at the top of vertical bar 33, and described vertical bar 33 is connected with slide bar 35 and is used as the slide block of slide bar 35, and described vertical bar 33 and pushing cylinder 34 The piston rod is connected; the passive mechanism 2 includes a vibration table 21 and a vibration gear 22, the vibration gear 22 is connec...

Embodiment 2

[0027] A vibration testing device, comprising a frame 1, a passive mechanism 2, and an active mechanism 3, the passive mechanism 2 is placed on the upper end of the frame 1, the passive mechanism 2 is connected to the lower end of the frame 1, and the active mechanism 3 is connected to the passive mechanism 3. The bottom of mechanism 2 cooperates by gear; Described driving mechanism 3 comprises spur rack 31, multi-layer damping ring 32, vertical bar 33, pushes cylinder 34 and slide bar 35, and the lower surface of described spur rack 31 is provided with multiple Layer shock absorbing ring 32, described multilayer shock absorbing ring 32 is positioned at the top of vertical bar 33, and described vertical bar 33 is connected with slide bar 35 and is used as the slide block of slide bar 35, and described vertical bar 33 and pushing cylinder 34 The piston rod is connected; the passive mechanism 2 includes a vibration table 21 and a vibration gear 22, the vibration gear 22 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com