Heat-resistant visual liquid position display device

A display device and high-temperature-resistant technology, which is applied in the directions of lubrication indicator devices, measuring devices, liquid level indicators, etc., can solve the problems of material waste, unfavorable accurate observation, etc., and achieve the advantages of convenient manufacture, convenient operation, and reduced use and maintenance costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

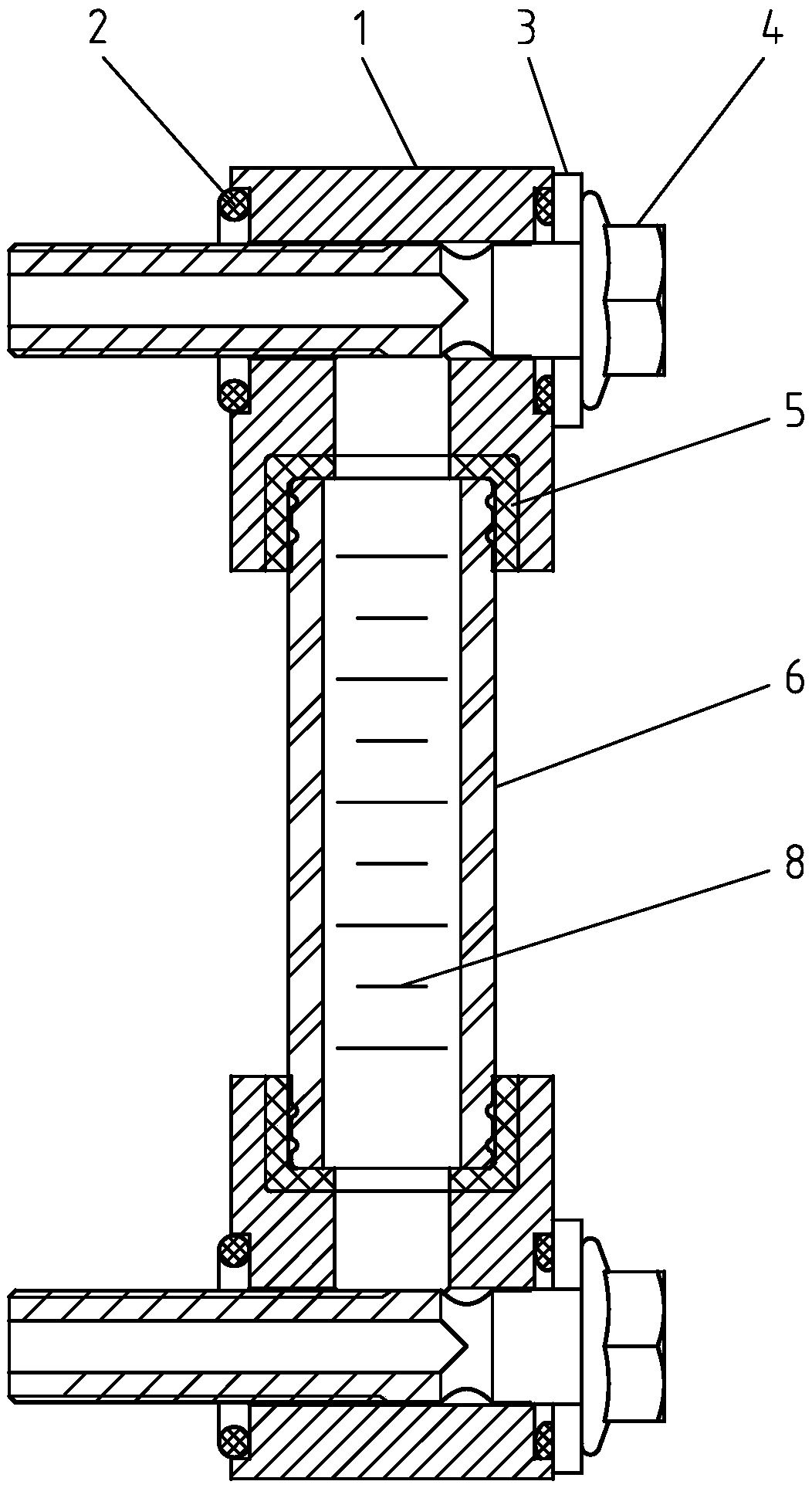

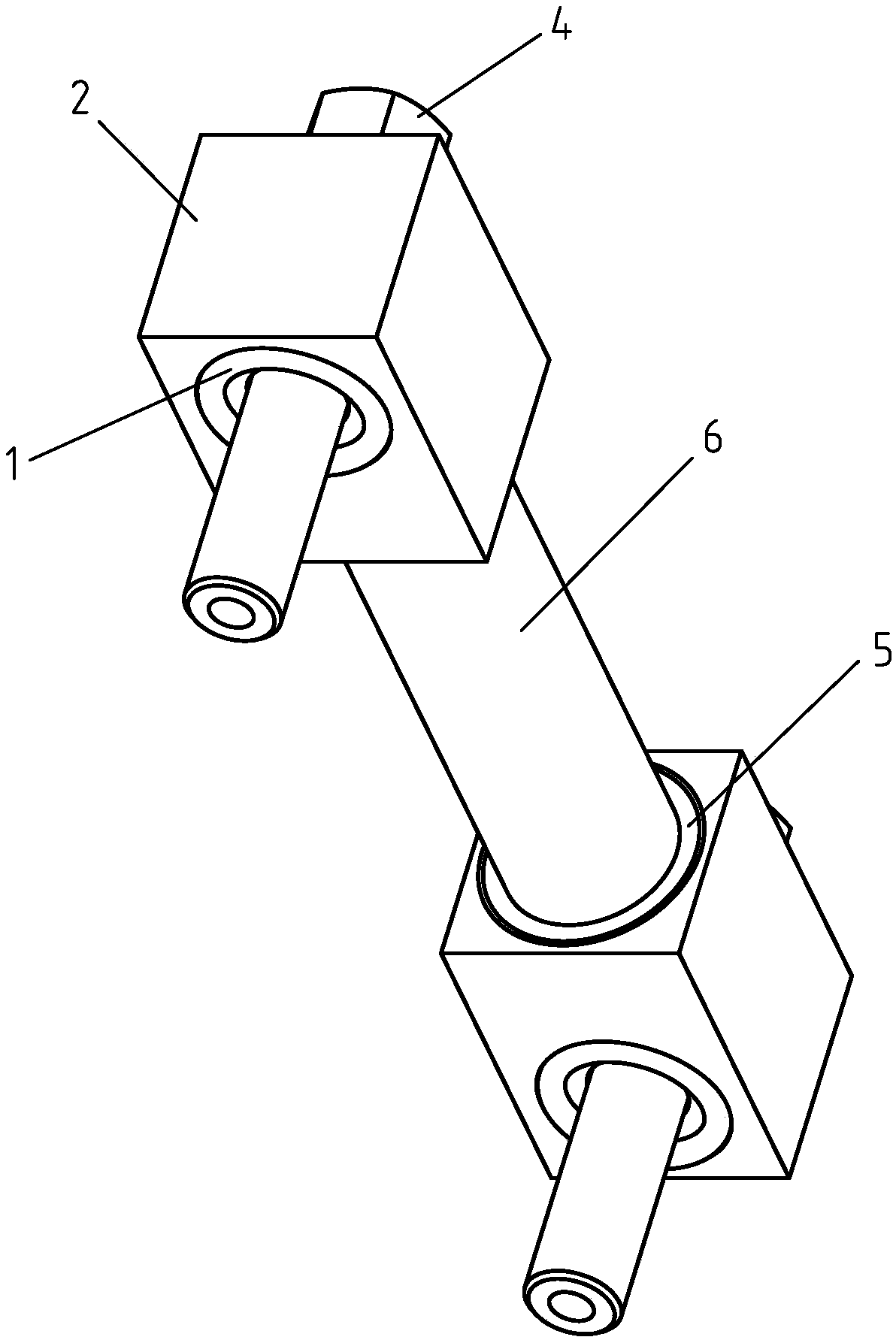

[0034] Reference figure 1 As shown in the figure, an invented high-temperature-resistant visualized liquid position display device includes upper and lower mounting blocks 1 and a tempered glass tube 6, and both ends of the tempered glass tube 6 are sealed and connected to the upper and lower mounting blocks 1 respectively The upper and lower mounting blocks 1 are connected to the liquid storage device by bolts 4. Both ends of the mounting block 1 are provided with "O"-shaped sealing rings. The tempered glass tube 6 is also provided with scale marks 8.

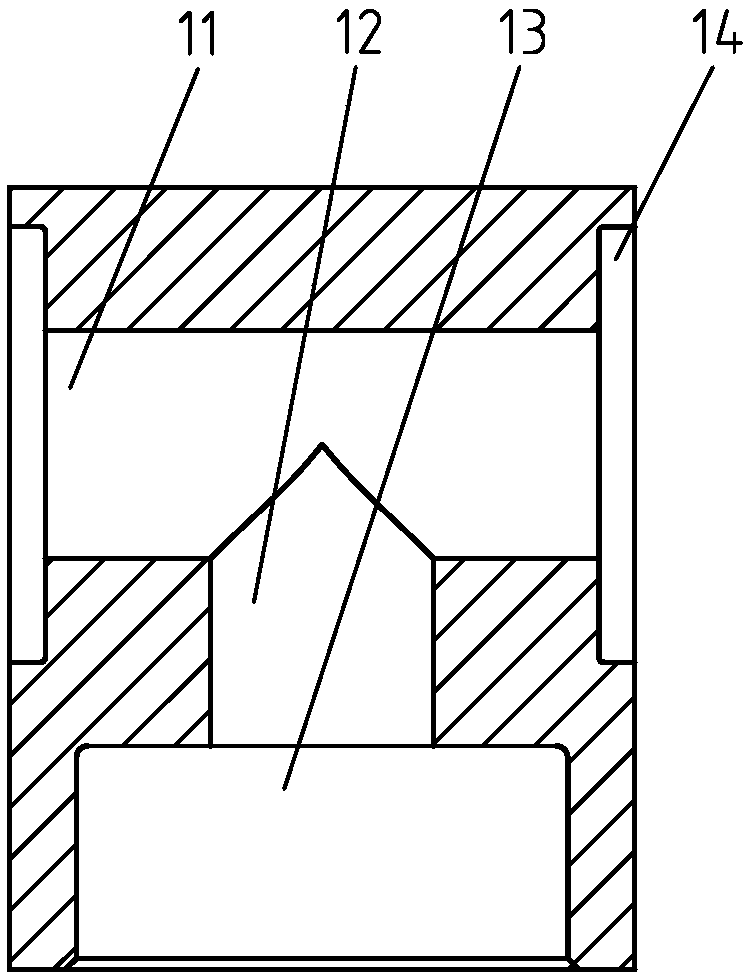

[0035] Combine Figure 3-Figure 6 , The upper and lower mounting blocks 1 are symmetrical in structure. Each mounting block 1 is provided with a "T"-shaped hole, and the "T"-shaped hole includes a longitudinal blind hole 12 communicating with the tempered glass tube 6 and a transverse through hole 11 for the bolt to pass through; The two ends of the through hole 11 are also provided with sealing ring installation grooves 14 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com