Online monitoring device and method for temperature field of indirect air cooling system

An air-cooling system and monitoring device technology, which is applied to measuring devices, thermometers, thermometer components, etc., can solve problems such as poor real-time performance, affecting unit efficiency, and freezing cracks of cooling pipes, so as to improve measurement accuracy and reduce inspection work. The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

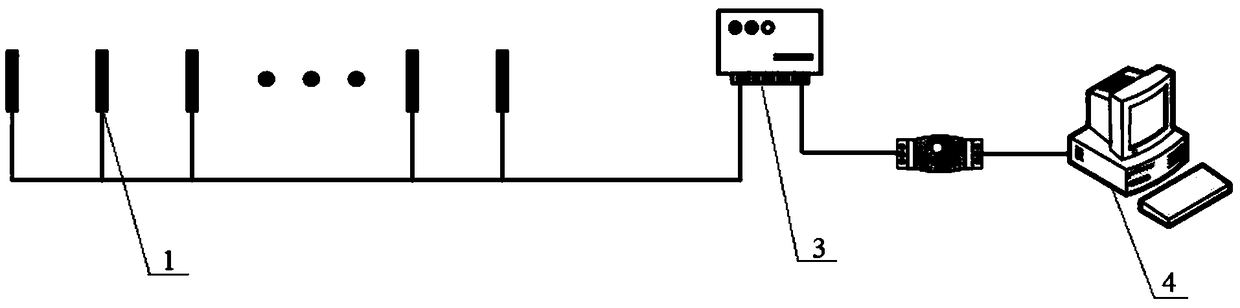

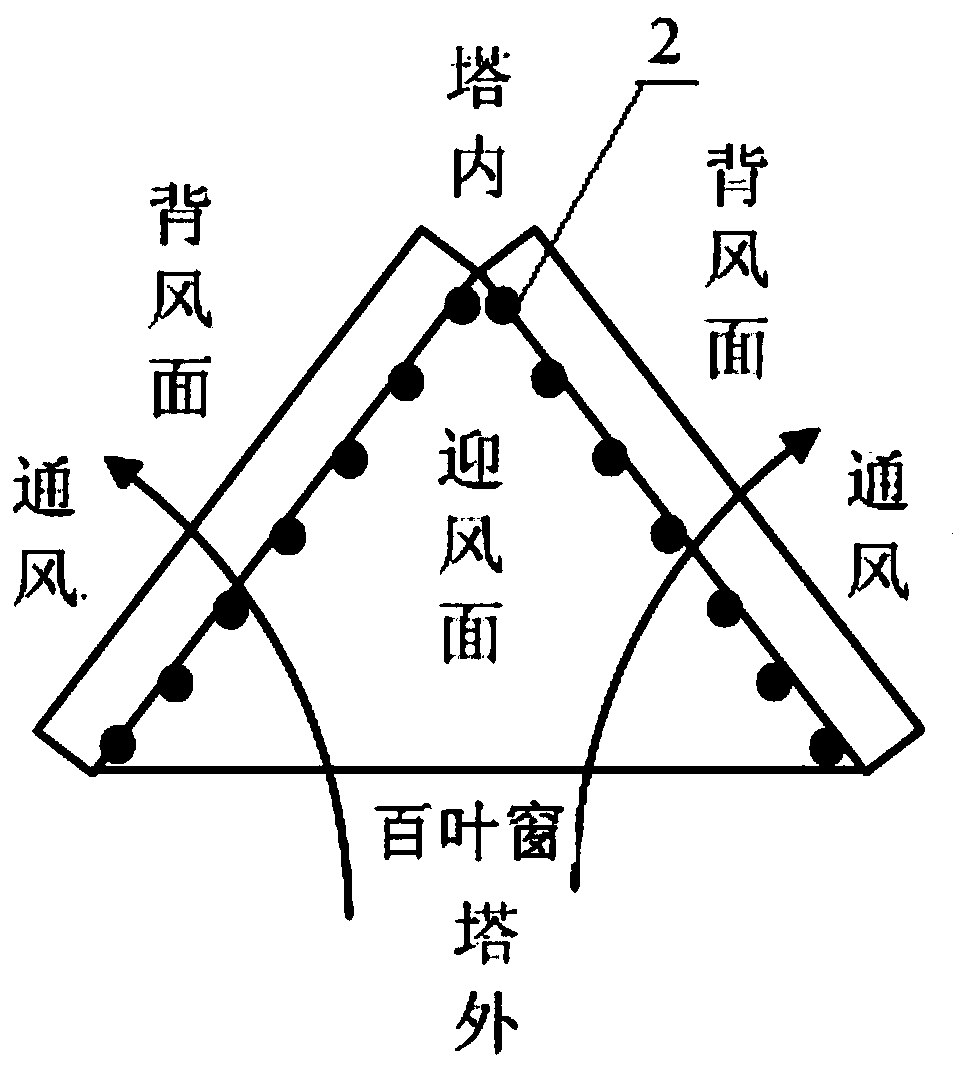

[0037] Example 1, such as Figure 1-2 As shown, an on-line monitoring device for the temperature field of an indirect air cooling system according to an embodiment of the present invention includes: several temperature measuring cables 1, several temperature measuring sensors 2 located on several temperature measuring cables 1, a collector 3 and a monitoring host 4 .

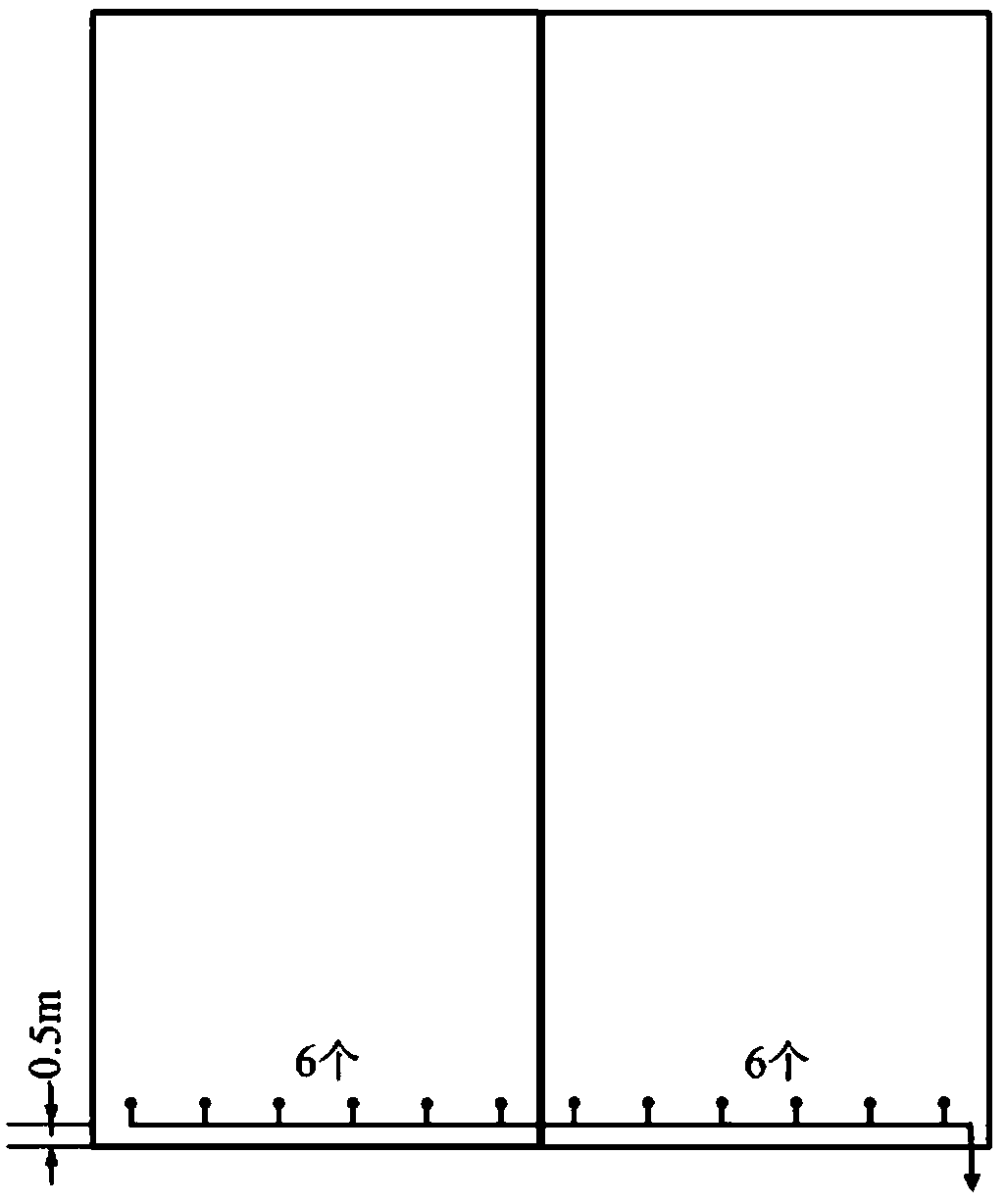

[0038] Several temperature measuring cables 1 are arranged on the windward side of the cooling triangle of the indirect air cooling system, and are located on the outer surface of the radiator tube bundle of the cooling triangle. Cable 1 is at the same level. Several temperature measuring sensors 2 are correspondingly arranged at certain intervals on several temperature measuring points of the temperature measuring cable 1 . Several temperature measurement cables 1 are connected to the collector 3, and the collector 3 is connected to the monitoring host 4.

[0039] A number of temperature measuring cables 1 a...

Embodiment 2

[0049] Embodiment 2, a monitoring method of an indirect air cooling system temperature field online monitoring device, comprising the following steps:

[0050] Step 1, arrange several temperature measuring cables 1 on the outer surface of the radiator tube bundle on the windward side of the cooling triangle of the indirect air cooling system, arrange one temperature measuring cable 1 on one windward side of a single cooling triangle, and arrange temperature measuring cables 1 on the two windward sides of a single cooling triangle 1 at the same level.

[0051] Step 2, arranging several temperature measuring sensors 2 at certain intervals on each temperature measuring cable 1 .

[0052] Step 3, connect several temperature measurement cables 1 to the collector 3, and connect the collector 3 to the monitoring host 4.

[0053] Step 4, several temperature measuring sensors 2 on several temperature measuring cables 1 respectively detect the temperature of the corresponding temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com