Rapid positioning and batch detection method for micro-defects on the surface of large-aperture optical crystals

An optical crystal, batch detection technology, applied in the field of optical engineering, can solve problems affecting the quality and efficiency of micro-defect repair, and achieve the effect of saving image acquisition efficiency and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

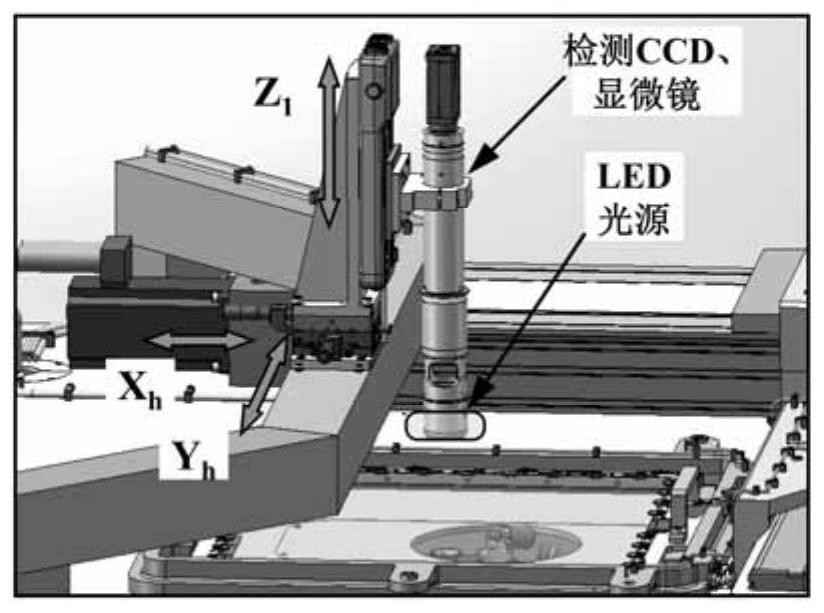

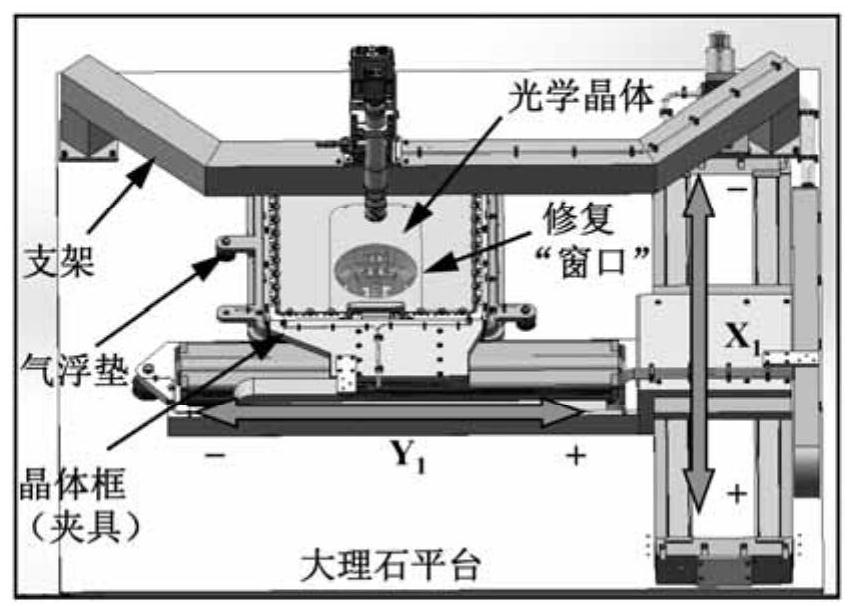

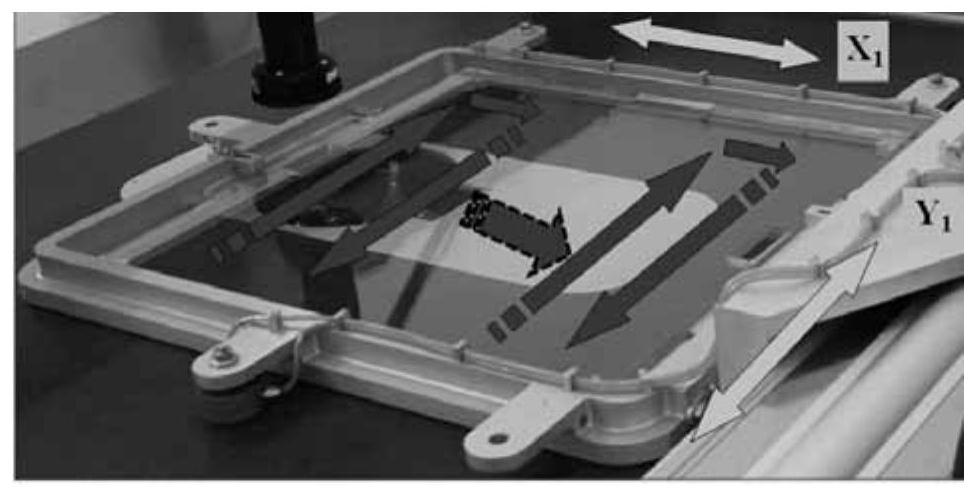

[0050] Specific implementation mode one: as Figures 1 to 7 As shown, the rapid location and batch detection method for micro-defects on the surface of large-aperture optical crystals described in this embodiment is implemented by the following steps:

[0051] 1. Install the optical crystal element to be tested, assemble and adjust the micro-defect detection microscope system, and automatically return to zero on each axis of the crystal element moving mechanism;

[0052] 2. Determine the actual magnification of the microscope based on the raster scanning path of large-diameter components, estimate the field of view of the CCD for defect detection under different magnifications, and select the scanning step for micro-defects on the surface of the entire crystal component;

[0053] 3. Compare the two scanning schemes of "continuous motion acquisition" and "intermittent stop acquisition" in terms of defect scanning efficiency and imaging quality, and formulate a reasonable scanni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com