Virtual assembly training system and method for machine manufacturing mold

A virtual assembly and mechanical manufacturing technology, applied in the field of virtual reality, can solve the problems of precision product damage, production accidents, high cost of mechanical damage, and difficulty in mold talents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] A training method for virtual assembly of mechanical manufacturing molds, which is applied to an electronic device. In this embodiment, the electronic device can be understood as a desktop computer or a notebook computer, but is not limited to these two.

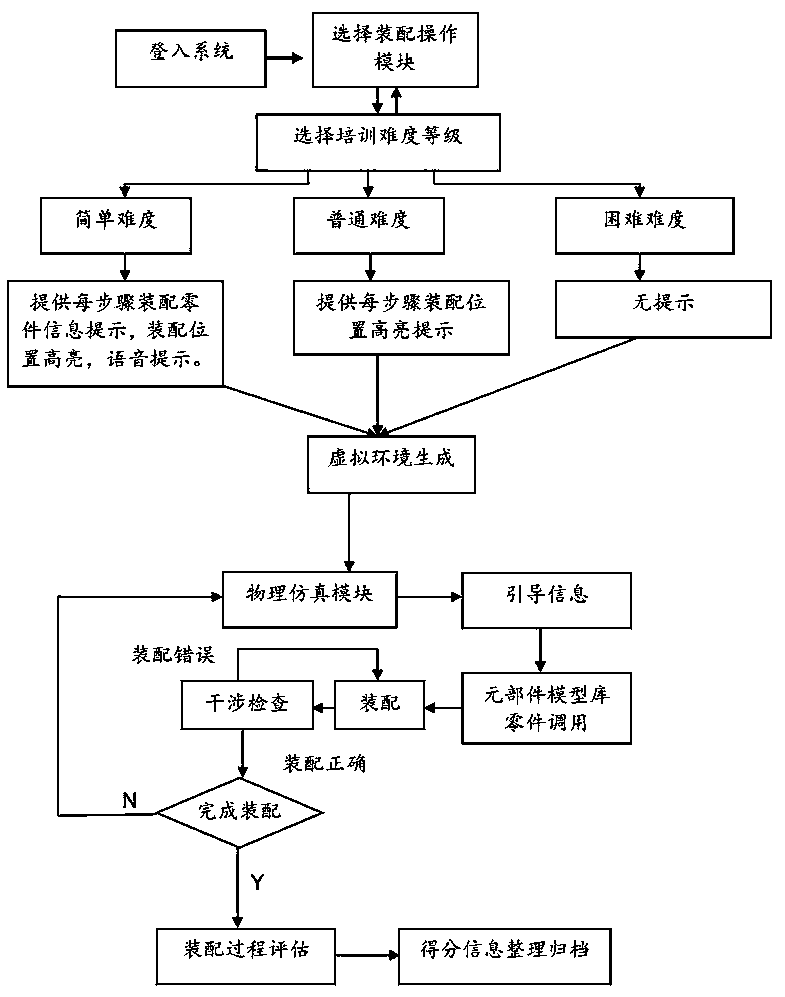

[0082] The methods include:

[0083] S1: Construct a training system integrating teaching, operation and evaluation; form a virtual assembly scene by the training system;

[0084] The training system includes virtual reality software and virtual reality equipment.

[0085] The virtual reality software includes a component model library module, a virtual reality scene generation module, an assembly teaching module, an assembly operation module and an assembly evaluation module; the training system calls each part in the component model library module through the virtual reality scene generation module The component model generates a virtual assembly scene, and the assembly teaching module, assembly operation module an...

Embodiment 2

[0126] Based on the same inventive idea as the teaching method for 3D animation assembly based on virtual reality in the foregoing embodiments, the present invention also provides a teaching device for 3D animation assembly based on virtual reality.

[0127] Specifically, the mechanical manufacturing mold virtual assembly training system includes a memory, a processor, and a computer program stored on the memory and operable on the processor, and the processor implements the following steps when executing the program:

[0128] S1: Construct a training system integrating teaching, operation and evaluation; form a virtual assembly scene by the training system;

[0129] S2: The user chooses to complete any or two or all of the functions of teaching, operation, and evaluation in the virtual assembly scene;

[0130] The training system includes virtual reality software; the virtual reality software includes a component model library module, a virtual reality scene generation module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com