Outer-rotor five-degree-of-freedom non-bearing switch reluctance motor

A technology of switched reluctance motors and outer rotors, which is applied to synchronous motors, synchronous machines, and electromechanical devices for single-phase currents, and can solve problems that are difficult to reflect the high speed and high power density of bearingless motors, long axial length, High critical speed and other issues, to achieve the effect of short axial length, less drive circuit and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

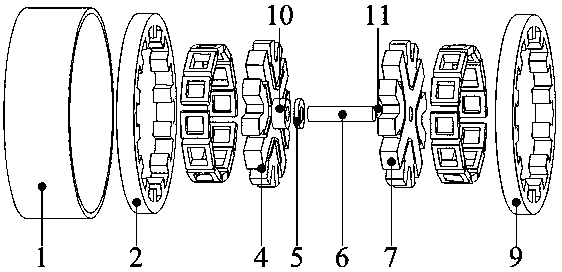

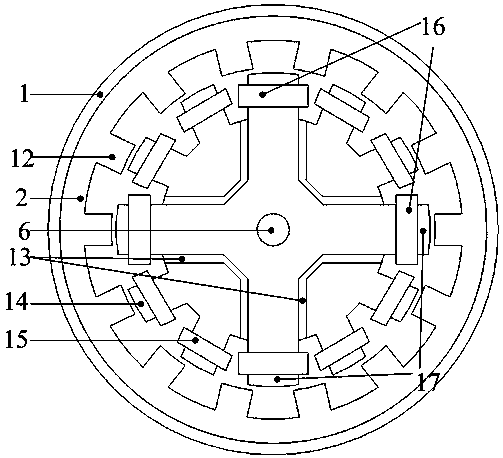

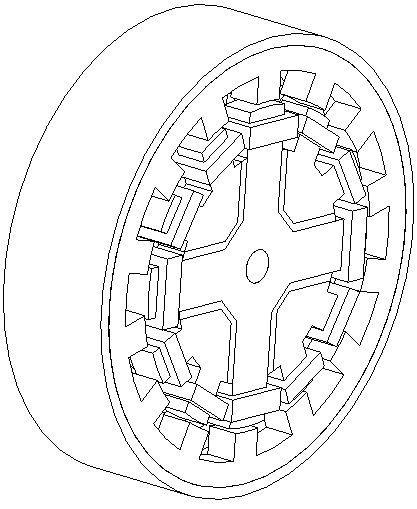

[0024] like Figure 1~3 A five-degree-of-freedom bearingless switched reluctance motor with an outer rotor includes a common inner stator and a common outer rotor. The common inner stator consists of a left stator core 4 serially connected in series on an absolute magnetic shaft 6, an axially magnetized The permanent magnet ring 5 and the right stator core 7 are composed of a left magnetic bridge 10 and a right magnetic bridge 11 respectively coaxially connected to the opposite surfaces of the left stator core 4 and the right stator core 7. The ends of the left magnetic bridge 10 and the right magnetic bridge 11 are respectively connected to two ends of the permanent magnetic ring 5 . The left stator core 4 and the right stator core 7 are respectively provided with four suspension teeth 17 in the x direction and y direction of the edge, and several torque teeth are connected between two adjacent suspension teeth 17 through a magnetic isolation block 13 14. The suspension teet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com