Magnetic direct drive type stirrer

A direct-drive, mixer technology, applied in the field of mixers, can solve problems such as bulky, inconvenient disassembly and assembly, complex structure, etc., and achieve the effects of simplifying the base mechanism, facilitating cleaning, and reducing transmission devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

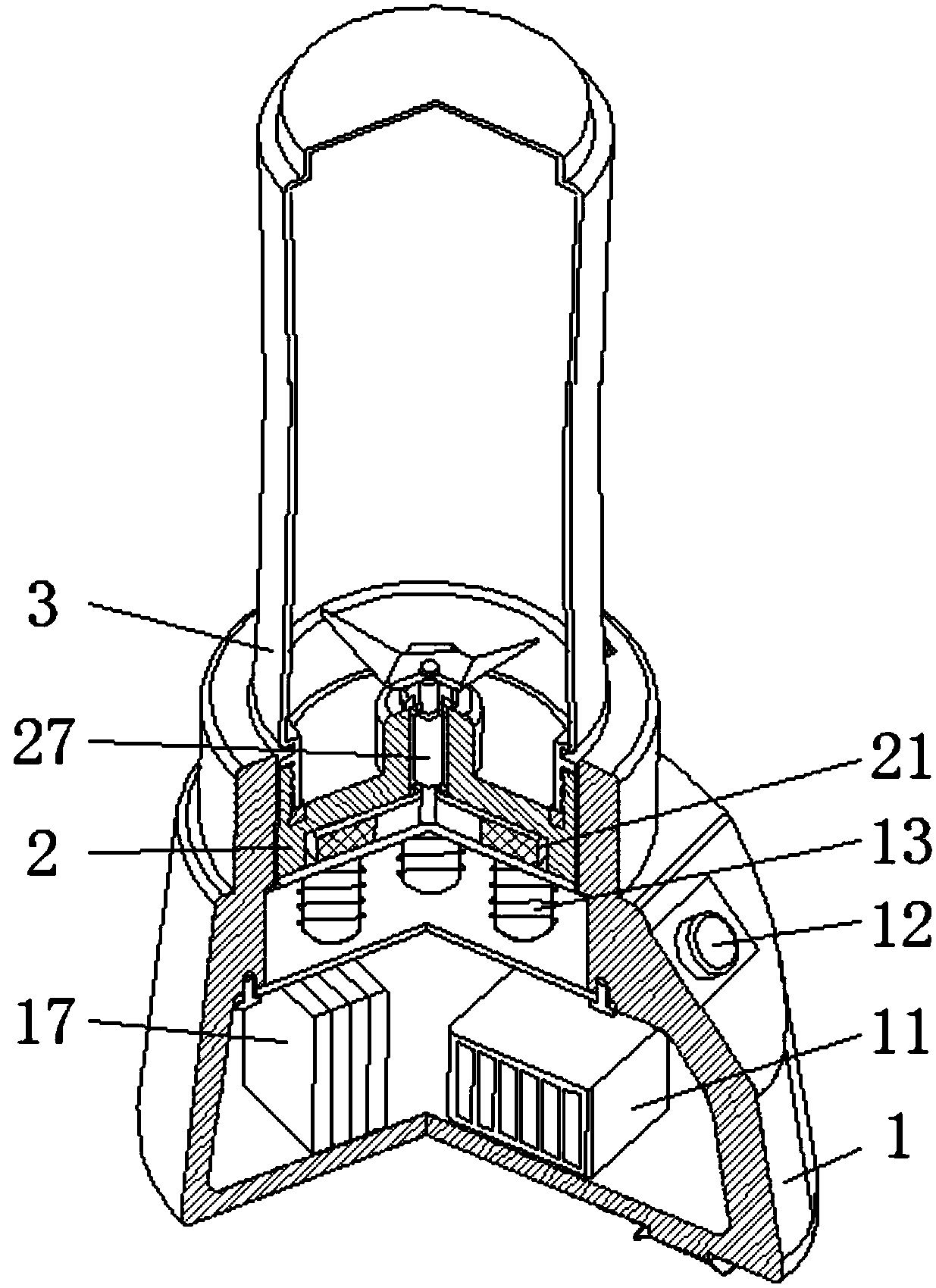

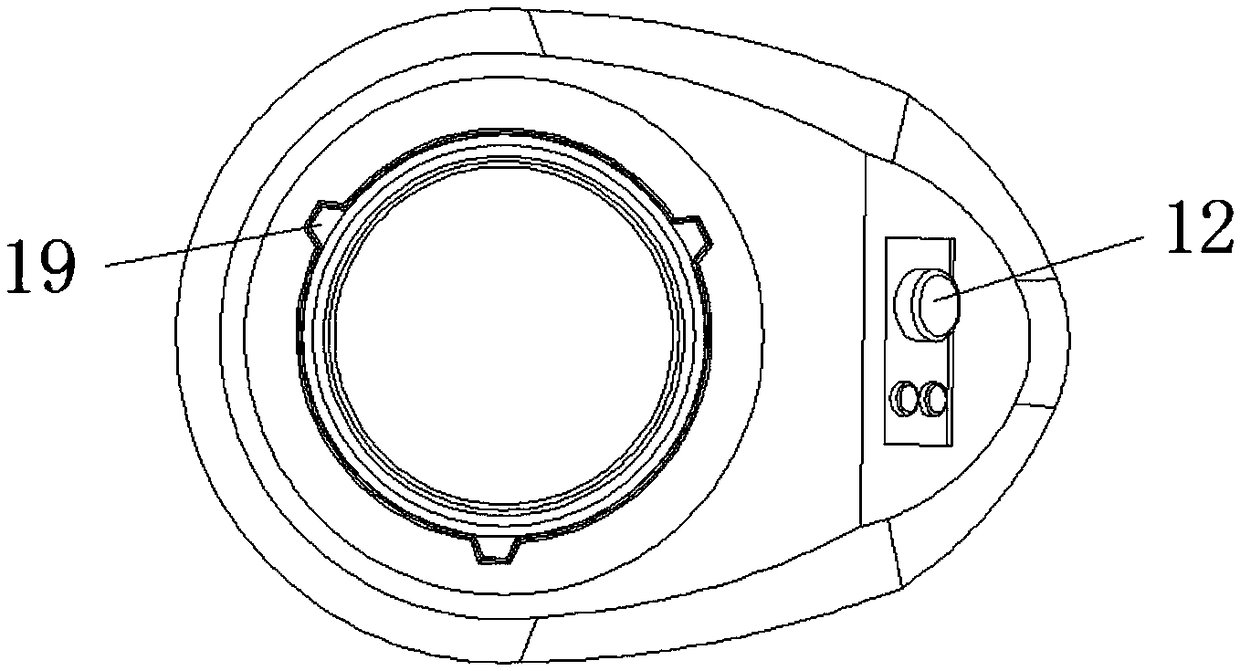

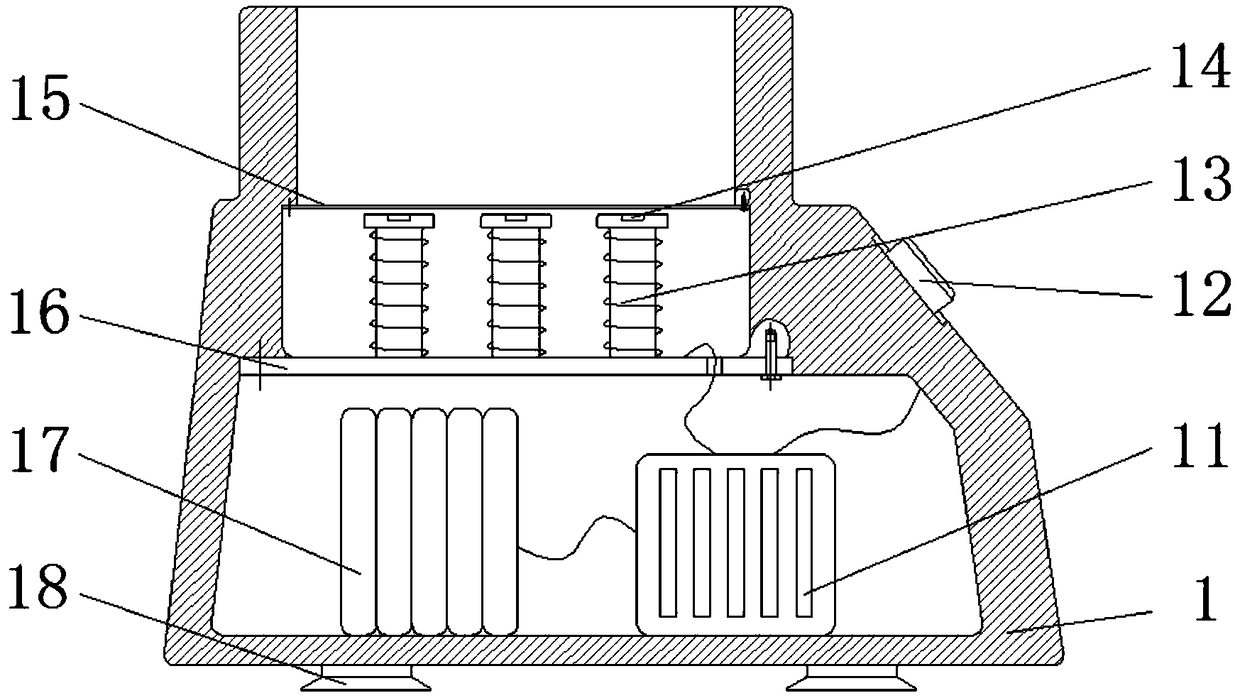

[0052] Embodiment 1 provided by the present invention is: a flat magnetic direct-drive mixer

[0053] Refer below Figure 1 to Figure 6 The application is further described, including a base 1, a cup cover 2 and a stirring cup 3, wherein the magnetodynamic active element-electromagnet group 13, the position sensor-Hall element 14 are arranged in the upper compartment of the base 1, the driver 11 and the The charging power supply 17 is arranged in the lower compartment of the base 1 . The bottom plate 16 is used to separate the upper and lower compartments of the base 1, the driven permanent magnet group 21 is arranged in the cup cover 2, and the base 1 and the cup cover 2 are connected in a plane.

[0054] The rechargeable power supply 17, the driver 11, and the electromagnet group 13 are connected in sequence, and then the driver 11 is connected to the control panel 12 in addition.

[0055] Three adjacent position sensors—Hall elements 14 are placed on the top of the electr...

Embodiment 2

[0064] Embodiment 2 provided by the present invention is a coaxial magnetic direct drive mixer

[0065] Refer below Figure 7 ~ Figure 10 The application is further described, including a base 1, a cup cover 2 and a stirring cup 3, wherein the magnetodynamic active element-electromagnet group 13, the position sensor-Hall element 14 are arranged in the upper compartment of the base 1, the driver 11 and the The charging power supply 17 is arranged in the lower compartment of the base 1 . The bottom plate 16 is used to separate the upper and lower compartments of the base 1 . The driven permanent magnet group 21 is arranged in the cup cover 2, and the base 1 and the cup cover 2 are connected by a concave-convex platform.

[0066] The electromagnet groups 13 are evenly arranged in a horizontal circle, and 12 are initially preferred, and a three-phase symmetrical star connection is adopted. The iron core of the electromagnet group 13 is made of stacked silicon steel sheets, whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com