A kind of trimodal pore distribution hydrodemetallization catalyst and preparation method thereof

A hydrodemetallization and catalyst technology, which is applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, catalyst carrier, etc., can solve the problems of low alumina pore volume, etc. The effect of continuous and improved activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

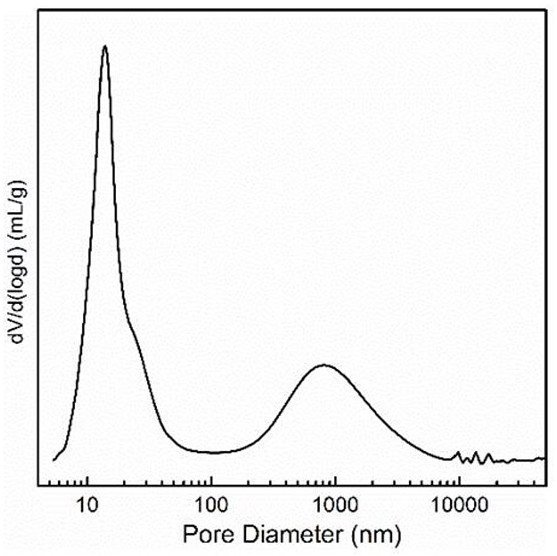

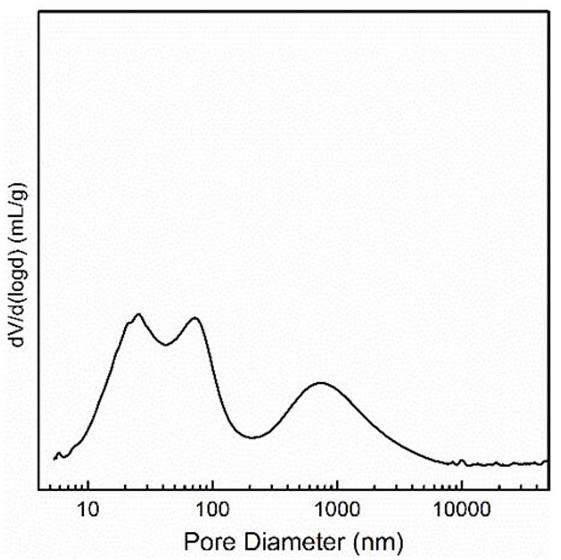

Image

Examples

Embodiment 1

[0023] Weigh 144 g of commercially available pseudo-boehmite P1 and 71 g of commercially available pseudo-boehmite P2, respectively, add 4.5 g of celadonite powder, and mix well. Add 250 g of dilute nitric acid solution (containing 3.0 g of nitric acid), knead it into a plastic body, and then extrude it into a four-leaf clover-shaped strip with a diameter of 1.3 mm on an extruder. The wet strip was dried at 120 °C for 4 h, and kept at 900 °C in a calcination furnace for 2 h to obtain alumina carrier A1.

[0024] Weigh 80 g of alumina carrier A1 and place it in a hydrothermal kettle. Weigh 8 g of deionized water into a glass. The glass is placed in a kettle of water. After sealing the hydrothermal kettle, put it into an oven, raise it to 220 °C, and conduct a constant temperature hydrothermal treatment for 6 h. The hydrothermally treated samples were dried at 120 °C for 4 h, and kept at a constant temperature of 500 °C for 2 h in a calcination furnace to obtain the hydrother...

Embodiment 2

[0026] Weigh 80 g of alumina carrier A1 and place it in a hydrothermal kettle. Weigh 20 g of deionized water into a glass. The glass is placed in a kettle of water. After sealing the hydrothermal kettle, put it into an oven, raise it to 220 °C, and perform constant temperature hydrothermal treatment for 6 hours. The hydrothermally treated samples were dried at 120 °C for 4 h, and kept at a constant temperature of 500 °C for 2 h in a calcination furnace to obtain the hydrothermally treated alumina carrier B2. The pore volume and pore size distribution are shown in Table 1.

Embodiment 3

[0028] Weigh 80 g of alumina carrier A1 and place it in a hydrothermal kettle. Weigh 40 g of deionized water into a glass. The glass is placed in a kettle of water. After sealing the hydrothermal kettle, put it into an oven, raise it to 220 °C, and conduct a constant temperature hydrothermal treatment for 6 h. The hydrothermally treated samples were dried at 120 °C for 4 h, and kept at a constant temperature of 500 °C for 2 h in a calcination furnace to obtain the hydrothermally treated alumina carrier B3. The pore volume and pore size distribution are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com