Mechanical arm for plate installing

A technology of mechanical arms and plates, applied in the directions of manipulators, conveyor objects, transportation and packaging, etc., can solve the problem of lack of mechanical arms for clamping glass installation plates, etc., to achieve easy engagement, easy lifting adjustment, and short production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

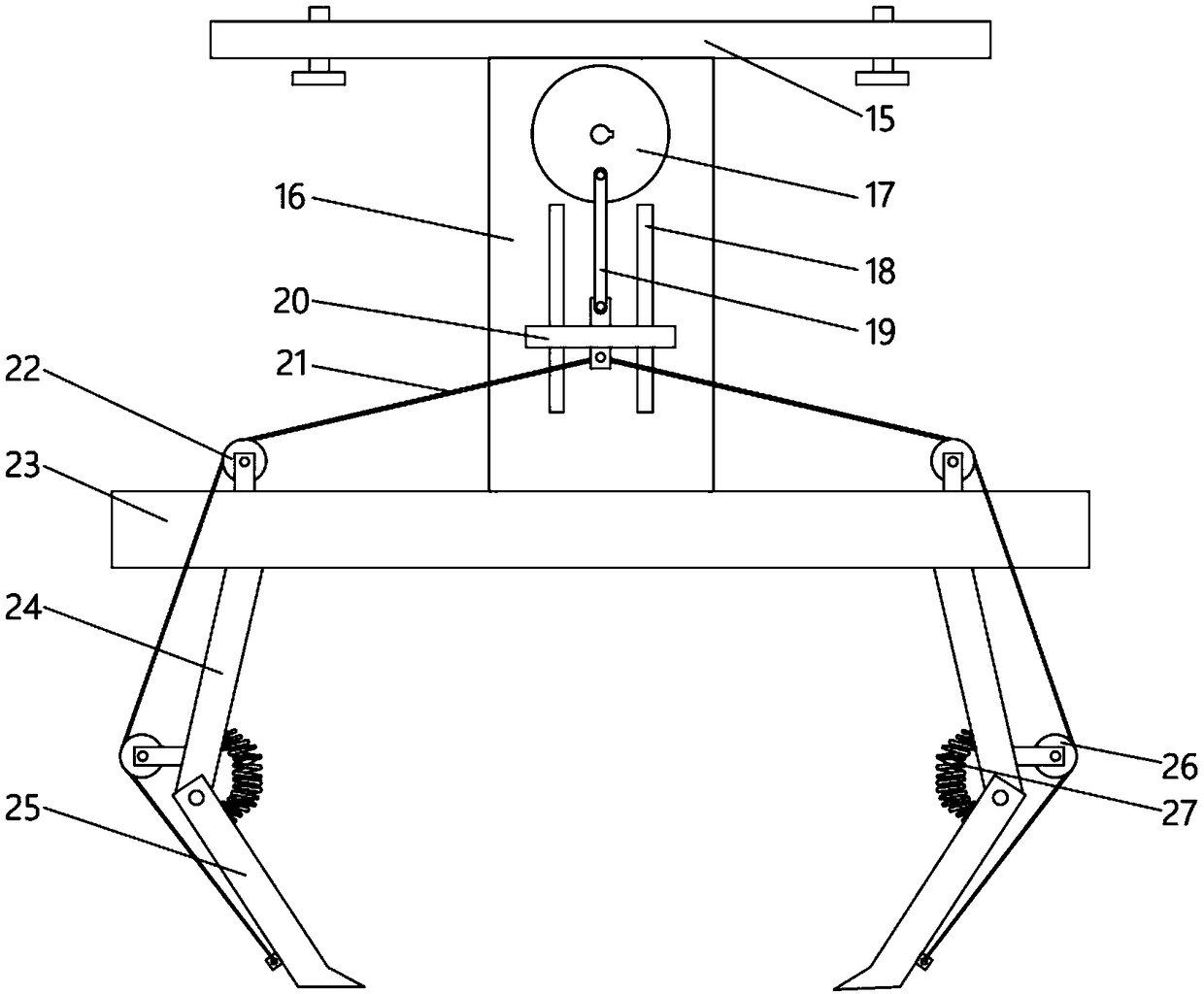

[0021] Embodiment 1: refer to figure 1 , a mechanical arm for plate installation, including a mounting plate 15, the end of the mounting plate 15 away from the hanging plate 8 is fixedly connected with a fixing plate 16, a second reduction motor is installed on the fixing plate 16, and the output shaft of the second reduction motor The wheel disc 17 is sleeved, and the output shaft of the second reduction motor is connected with the wheel disc 17 through an interference fit through a flat key. The interference fit connection process is simple and the connection is stable. One end of the rod 19 away from the wheel disc 17 is rotatably connected with a connecting frame 20, the connecting frame 20 is slidably connected to the fixed plate 16, the fixed plate 16 is provided with a T-shaped groove 18, and the connecting block 20 is fixedly connected with a T-shaped block, and the T Type groove 18 is slidingly connected with T-shaped block, and T-type groove is convenient for install...

Embodiment 2

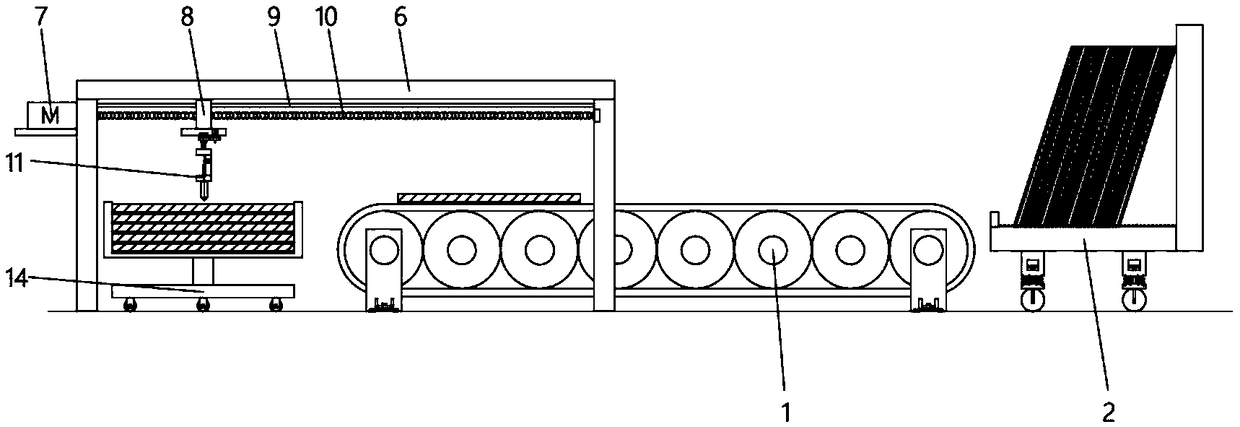

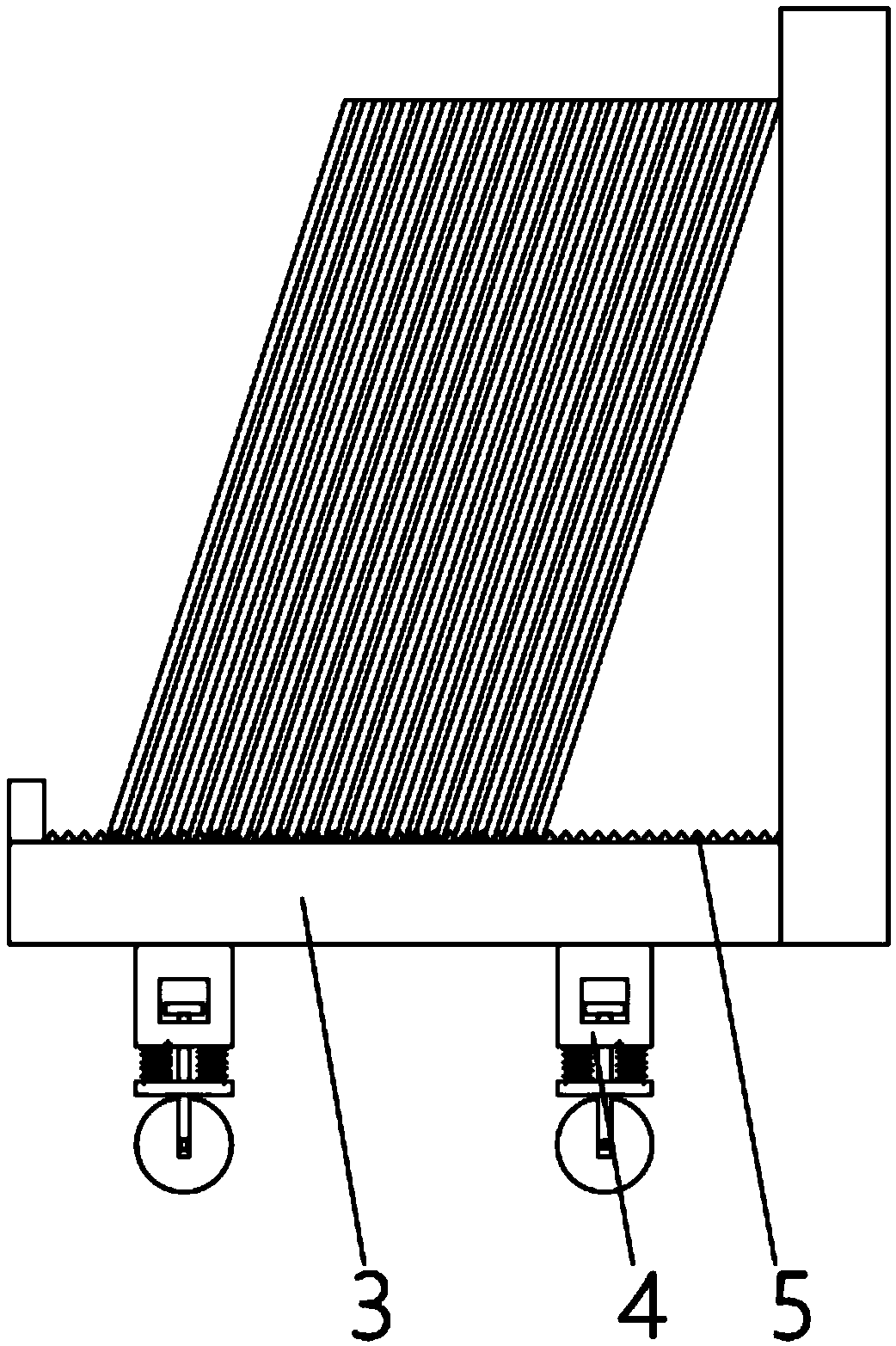

[0022] Embodiment 2: refer to Figure 1-4 , applying the present invention to a fully automatic sheet material installation manipulator device, comprising a sheet material transfer device 1, a gantry frame 6, a first trolley 2 and a second trolley 14, the first trolley 2 includes a The base 3 and the backrest are formed, the upper end of the base 3 is provided with a plurality of sawtooth grooves 5, the bottom end of the base 3 is equipped with a plurality of buffer travel mechanisms 4, and the lower end of the base 3 is slidably connected with a plurality of limit columns, and the limit column The lower end is provided with a roller frame, and a spring shock absorber is provided between the roller frame and the base 3, and each group of roller frames is rotatably connected with rolling wheels, and each rolling wheel is provided with anti-slip lines, and the setting of the buffer traveling mechanism 4 can Buffering and shock absorption prevents the glass from being damaged. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com