Production method of plastic packaging bags

A production method and packaging bag technology, applied in the field of plastic bag production, can solve the problems of reducing heat sealing speed, tearing plastic film, plastic film deformation, etc., and achieve the effect of increasing production speed, increasing heat sealing speed, and avoiding water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

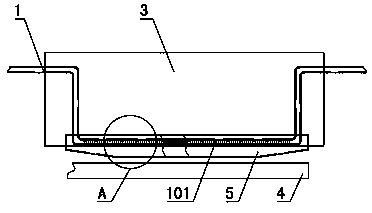

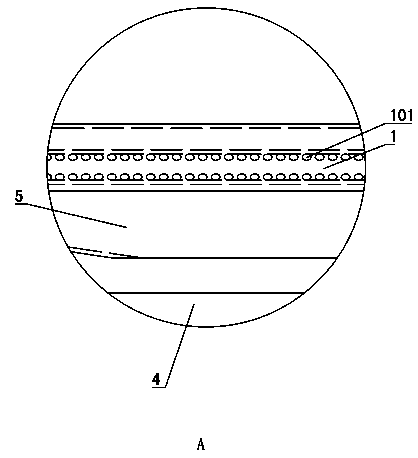

[0032] A production method of a plastic packaging bag, comprising the steps of:

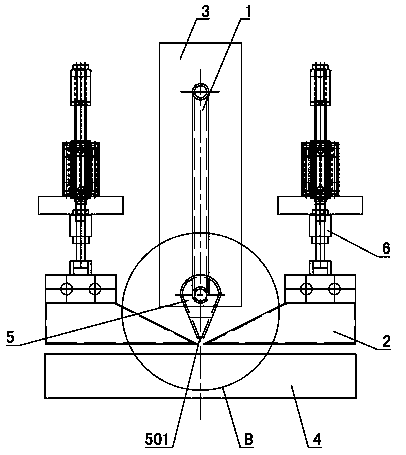

[0033] Shaping, using shaping rollers to shape the plastic film, and cutting the plastic film after shaping, pulling the cut plastic film and relying on the molds on both sides to make the two sides of the plastic film overlap to form a cylindrical shape;

[0034] The shaping roller is used to shape the plastic film, that is, the shaping roller rotates, and the plastic film bypasses the shaping roller with a certain tension, thereby completing the shaping of the plastic film. The traditional shaping uses a cylindrical shaping roller, which is simple to manufacture and low in cost, but when the tension of the plastic film roll is uneven, it will cause creases on the edge of the film. In this embodiment, the shaping roller is a polygonal roller, which avoids the problem of creases on the edges due to uneven tension of the film roll. The plastic film is then cut according to the size of the plastic...

Embodiment 2

[0054] A production method of a plastic packaging bag, comprising the steps of:

[0055] Shaping, using shaping rollers to shape the plastic film, and cutting the plastic film after shaping, pulling the cut plastic film and relying on the molds on both sides to make the two sides of the plastic film overlap to form a cylindrical shape;

[0056] The shaping roller is used to shape the plastic film, that is, the shaping roller rotates, and the plastic film bypasses the shaping roller with a certain tension, thereby completing the shaping of the plastic film. The traditional shaping uses a cylindrical shaping roller, which is simple to manufacture and low in cost, but when the tension of the plastic film roll is uneven, it will cause creases on the edge of the film. In this embodiment, the shaping roller is a polygonal roller, which avoids the problem of creases on the edges due to uneven tension of the film roll. The plastic film is then cut according to the size of the plastic...

Embodiment 3

[0064] A production method of a plastic packaging bag, comprising the steps of:

[0065] Shaping, using shaping rollers to shape the plastic film, and cutting the plastic film after shaping, pulling the cut plastic film and relying on the molds on both sides to make the two sides of the plastic film overlap to form a cylindrical shape;

[0066] The shaping roller is used to shape the plastic film, that is, the shaping roller rotates, and the plastic film bypasses the shaping roller with a certain tension, thereby completing the shaping of the plastic film. The traditional shaping uses a cylindrical shaping roller, which is simple to manufacture and low in cost, but when the tension of the plastic film roll is uneven, it will cause creases on the edge of the film. In this embodiment, the shaping roller is a polygonal roller, which avoids the problem of creases on the edges due to uneven tension of the film roll. The plastic film is then cut according to the size of the plastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com