Special loading and unloading equipment for cantilever railway containers and operation method

A loading and unloading equipment and container technology, applied in the direction of transportation and packaging, trolley cranes, load hanging components, etc., can solve the problems of poor overall efficiency, low efficiency, and large equipment, and achieve good positioning and control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

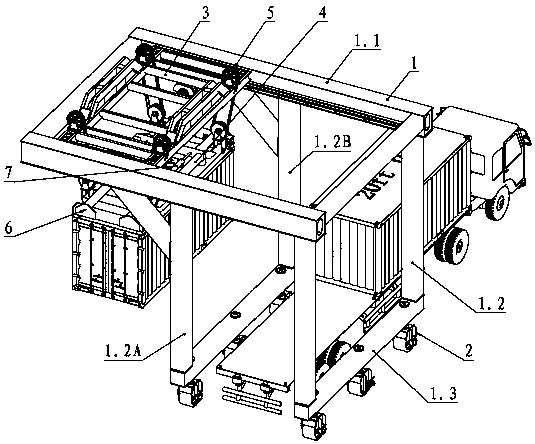

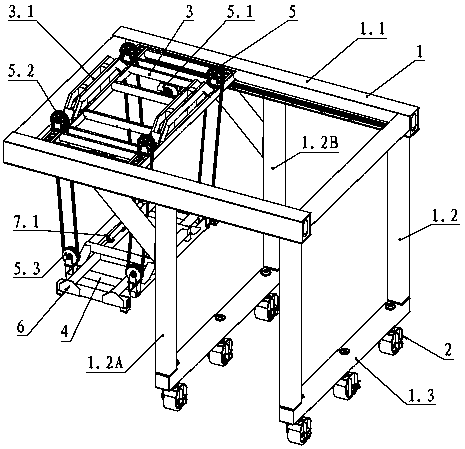

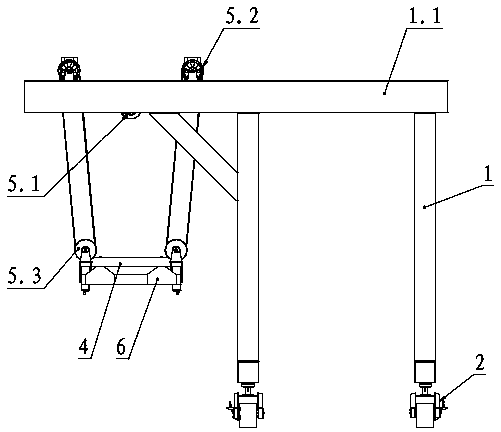

[0063] The first embodiment of the present invention is Figure 1-4 As shown, a cantilever type special loading and unloading equipment for railway containers is a basic structural type, mainly composed of a portal frame 1, a cart traveling device 2, a trolley traveling device 3, a lifting frame 4, a lifting device 5, a crane It is composed of tool 6, spreader control device 7, etc. It is characterized in that: the portal frame 1 is mainly composed of two main beams 1.1 at the top, column 1.2 and bottom beam 1.3, etc., the main body is a four-column frame structure, and the portal frame 1 is located on one side of the railway line, and the two main girders 1.1 cantilever out above the railway container train, such as figure 1 , figure 2 and Figure 5 , Figure 6 As shown, horizontally (perpendicular to the direction of the railway line) between the two columns 1.2A and 1.2B on the side of the portal frame 1 close to the railway line can allow horizontally hoisted container...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com