Plain weave plastic knitting machine

A technology of plastic weaving machine and plain weaving, applied in looms, textiles, textiles and papermaking, etc., can solve problems such as reducing the response speed and service quality of after-sales service, increasing the mental workload of technicians, and unable to realize remote fault diagnosis. , to avoid duplication of labor, save manpower, and improve processing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with specific illustrations.

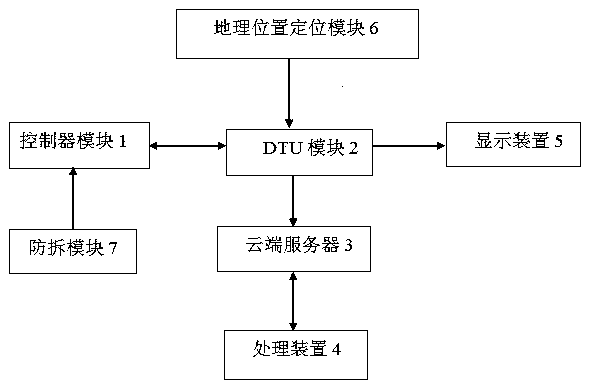

[0040] refer to figure 1 , a flat weaving plastic knitting machine, comprising an opening mechanism, a water jet weft insertion mechanism, a weft beating mechanism, a let-off mechanism, a coiling mechanism and an auxiliary mechanism;

[0041] The auxiliary mechanism includes a frame mechanism, an electronic weft cutter device and an electronic weft feeding device;

[0042] The electronic weft yarn cutter device includes a controller module 1, a current relay, a current transformer, a No. 1 copper terminal, a No. 2 copper terminal and a resistance wire for scalding the weft yarn. The controller module 1 is connected to the current relay, and the current relay is connected to the current mutual inductance The current transformer is connected to the No. 1 copper terminal and the No. 2 copper terminal. One end of the resistance wire is connected to the No. 1 copper terminal,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com