Rain-sewage shunting type rainwater opening structure

A rainwater diversion and rainwater outlet technology, which is applied in the direction of sewage discharge, drainage structures, waterway systems, etc., can solve problems such as the inability to realize rainwater diversion, and achieve the effects of convenient implementation, simple structure, and convenient dredging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

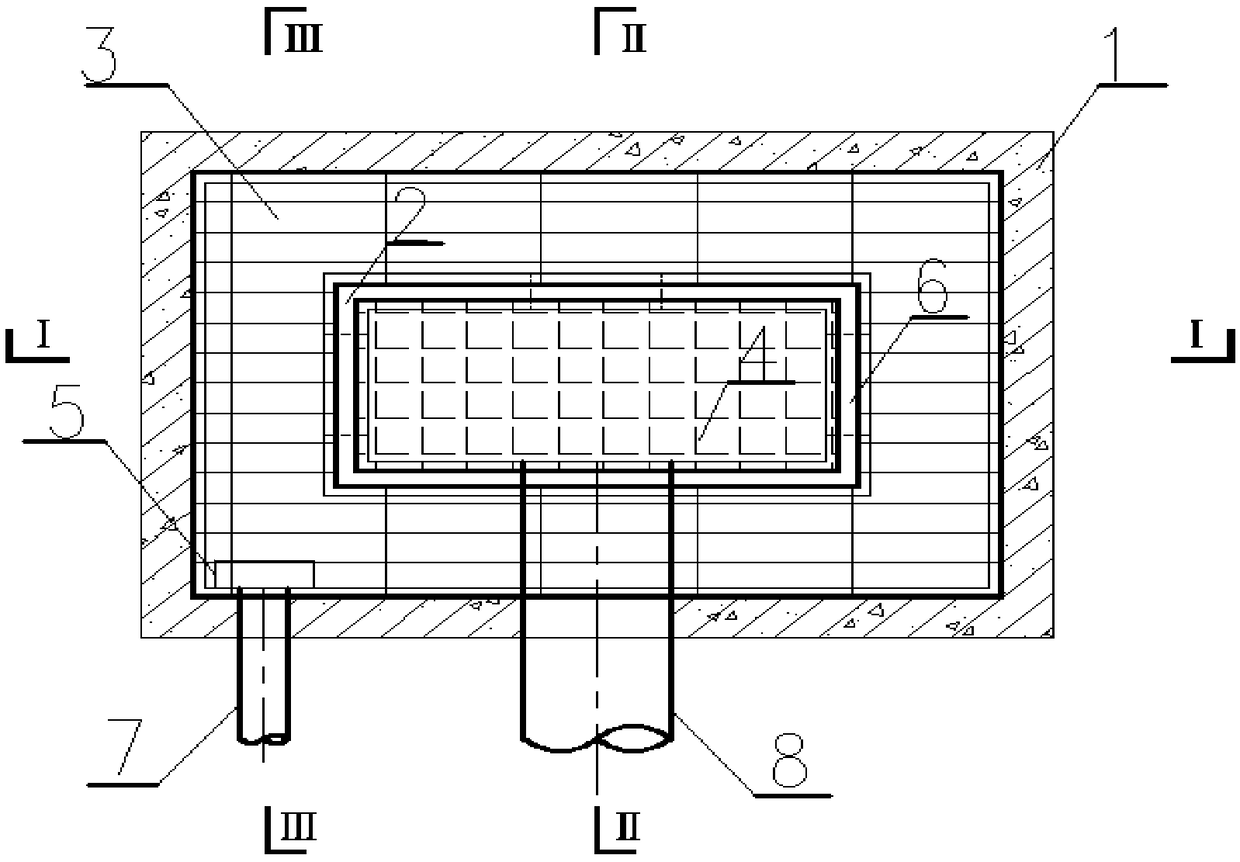

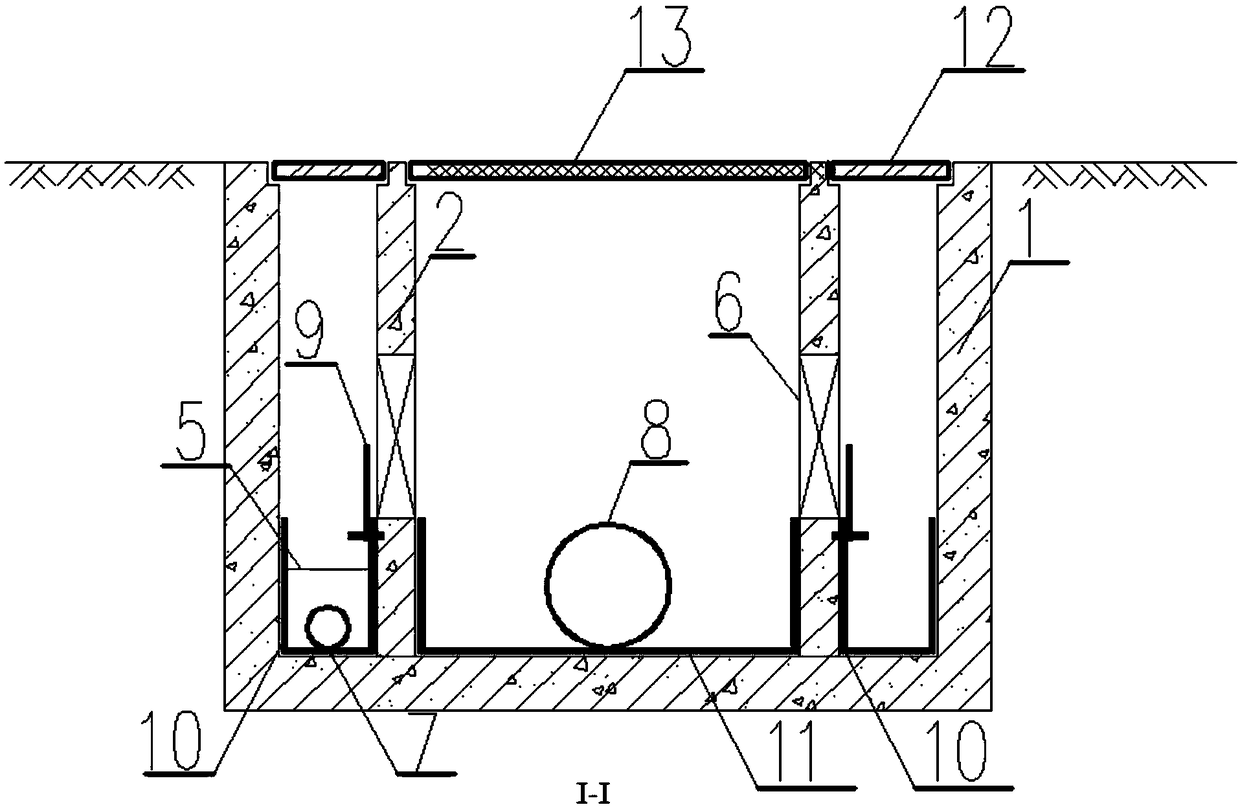

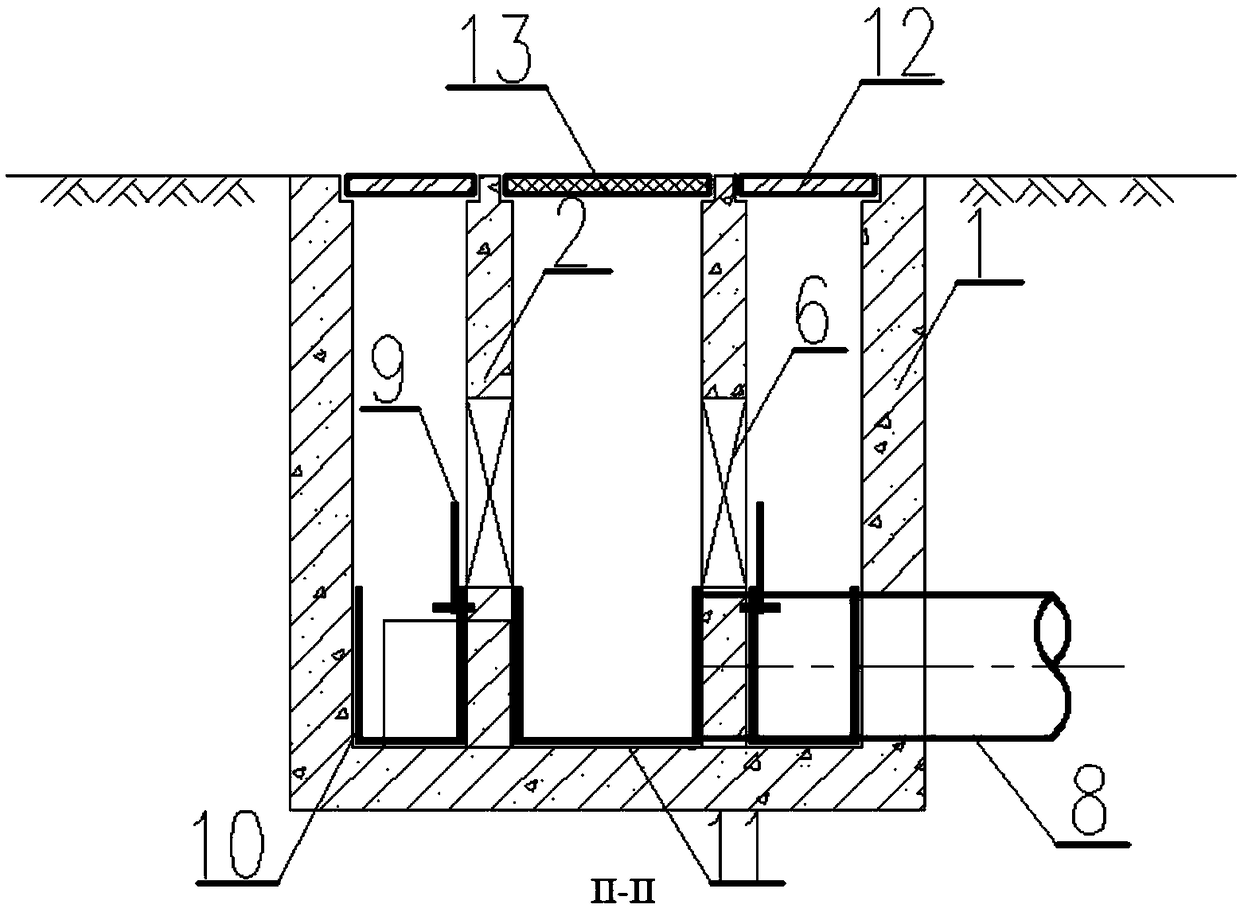

[0050] Simulate the situation where sewage from restaurants and restaurants pours into roadside storm drains. The rectangular ring area 3 is a sewage collection area covered with a rectangular ring cover plate 12 . Sewage is engraved on the cover plate of the rectangular ring. After the sewage is quickly poured into the rectangular ring area 3, the liquid level rises to the liquid level 1. After the sewage is filtered by the filter screen 5, the impurities remain in the rectangular ring dredging bucket 10, and the sewage is discharged into the sewage system through the sewage pipe 7 and finally reaches the Sewage plant treatment and disposal isolates the sewage from flowing into the rainwater system. Rectangular ring dredging bucket 10 can regularly propose dredging.

Embodiment 2

[0052] Simulate the situation of rainwater flowing into the roadside gullies when the initial rainwater is intercepted, see Image 6. In the early stage of rainfall, the initial rainwater first collects into the rectangular ring area 3, and the liquid level continues to rise to the liquid level 1. At this time, the initial rainwater flows to the sewage treatment system through the sewage pipe 7 for treatment, and the initial rainwater, including the pollutants therein, is discarded. flow. As the rainfall increases, the liquid level gradually rises to the liquid level 2 and turns over the adjustable weir plate 9. There are multiple threaded holes at intervals of 20 cm on the weir plate, and the threaded holes cooperate with the screws embedded in the wall to realize Adjustment for different heights.

[0053] And after entering the rectangular area 4 through the water-passing square hole 6, the rainwater is discharged into the rainwater system through the rainwater pipe 8 to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com