Radiator, cold forging process of radiator and lamp

A technology for radiators and lamps, applied in lighting and heating equipment, cooling/heating devices of lighting devices, lighting devices, etc., can solve the problem of lamps that cannot meet the heat dissipation requirements, large thickness and draft angle, poor heat dissipation, etc. problem, to achieve the effect of shortening the production cycle, improving the service life and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

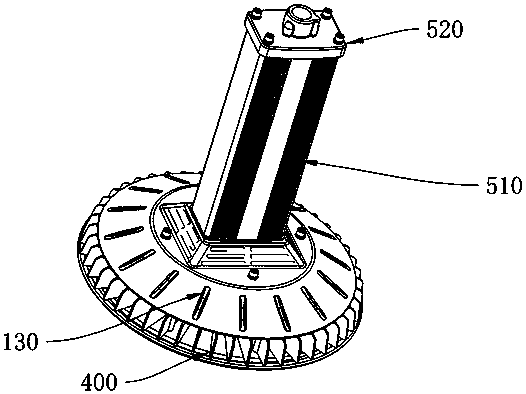

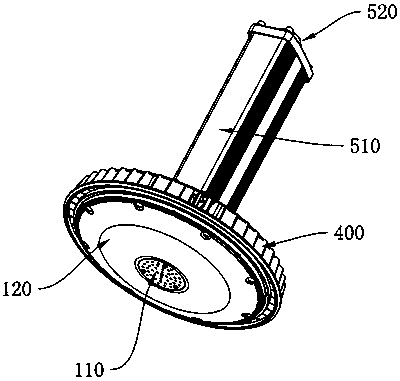

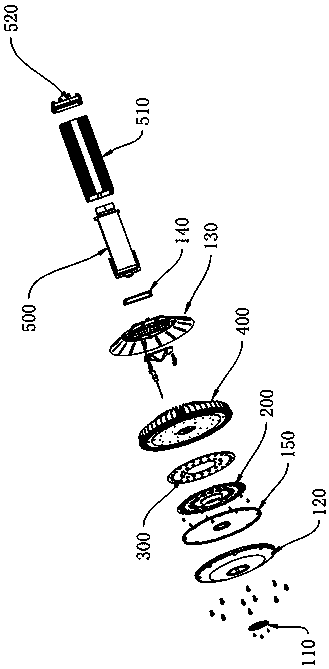

[0036] see Figure 1-Figure 3 , a lamp comprising a ventilating plate 110, a transparent cover 120, a first casing sealing ring 150, a reflector 200, a light source board 300, and a radiator 400, and the light source board 300 and the reflector 200 are all fixed on the radiator 400 , and the light source board 300 is put into the light source and installed on the left side of the reflector ( image 3 prevail), the light source emits light after the light source board is energized, and the reflector reflects the light;

[0037] The radiator 400 is also sealed and assembled with the transparent cover 120 through the first housing sealing ring 150, and the transparent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com