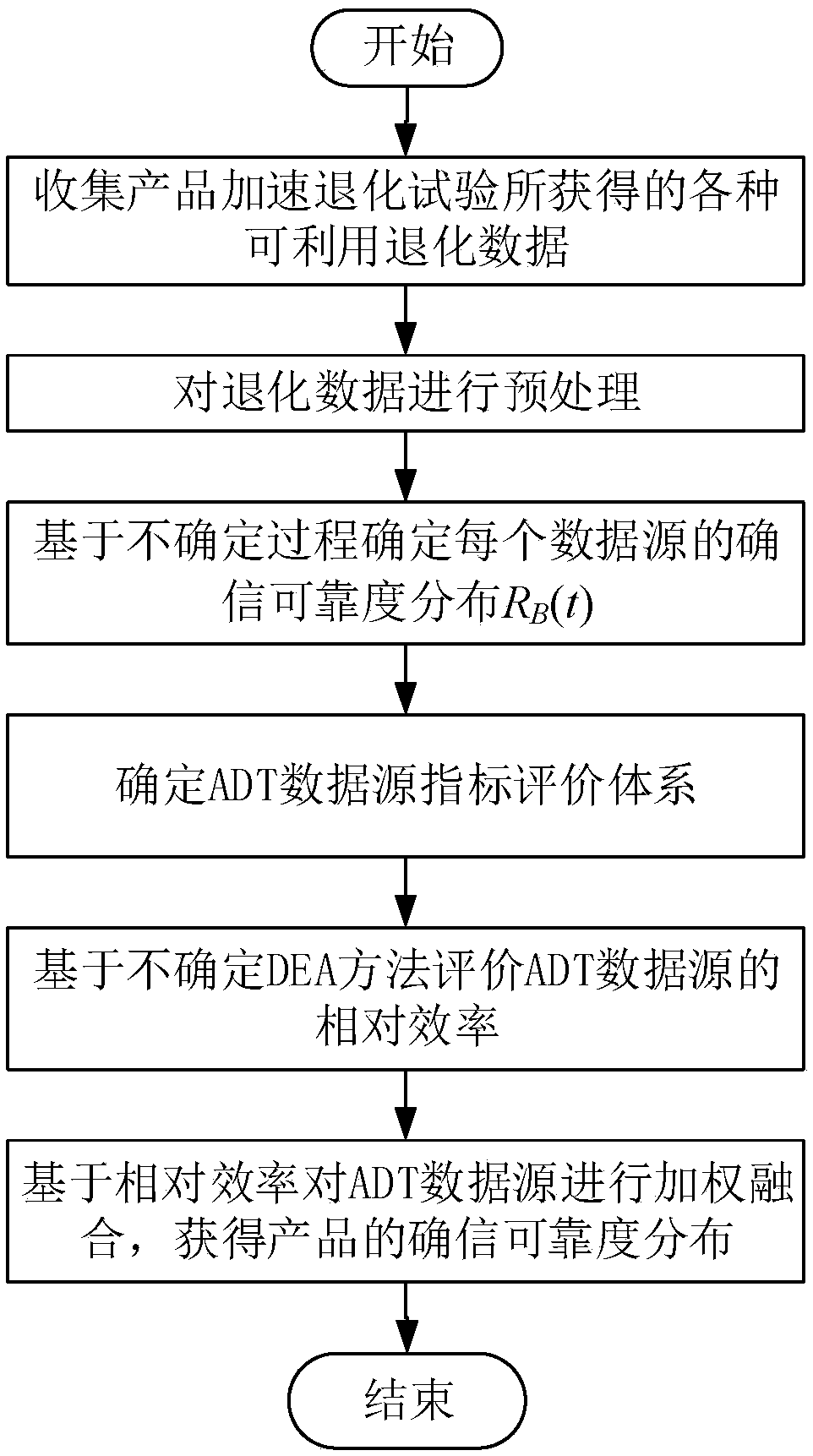

Modeling method of accelerated degradation information fusion based on uncertain data envelopment analysis

A technology of accelerated degradation and envelope analysis, applied in the fields of electrical digital data processing, special data processing applications, design optimization/simulation, etc., can solve problems such as lack of overall product information cognition, multi-source ADT data sources cannot be fully utilized, etc. Achieve the effect of improving the accuracy of reliability and life assessment and reducing cognitive uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

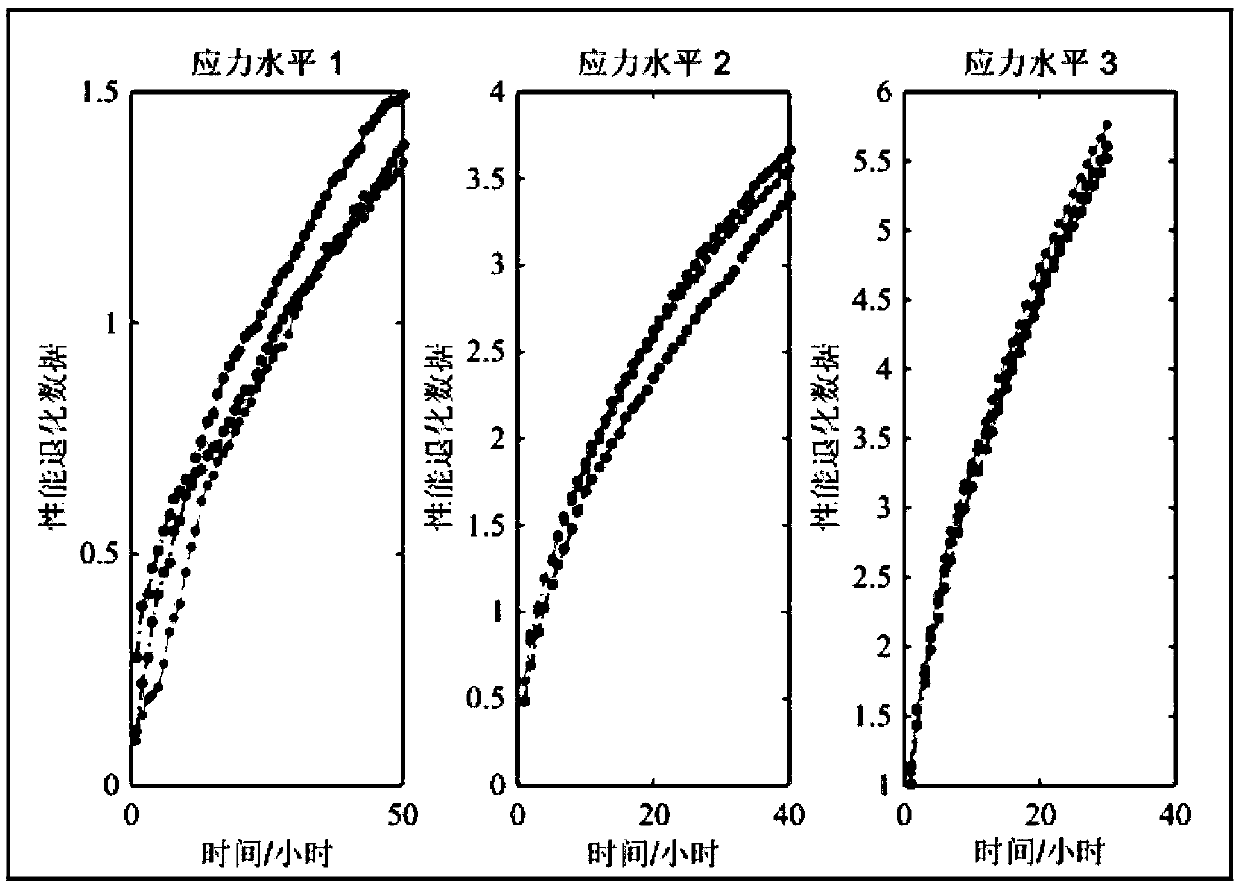

[0204] Based on the above theory, the multi-source ADT data of a battery product under the same stress conditions are fused and evaluated by numerical simulation method.

[0205] Step 1. Collect various available degradation data obtained by the product ADT and perform data preprocessing;

[0206] Assuming that a product has undergone two stages of ADT before it is put into production, through data collection and arrangement, the data set test plan and simulation parameters are shown in Table 1 and Table 2.

[0207] Table 1 Simulation data test plan

[0208] data set

stress type

Detection times

sample size

D 1

temperature(℃)

50,80,100

50,40,30

3

D 2

temperature(℃)

60,90

60,40

6

[0209] Table 2 Simulation parameters

[0210]

[0211] Since the data has a decreasing trend, the data of the simulation test is preprocessed to obtain the data set D 1 and D 2 The simulation data such as image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com