Local smart feeder automation no-delay stage difference coordination method and application

A technology of feeder automation and differential coordination, which is applied in the direction of automatic disconnection emergency protection devices, electrical components, circuit devices, etc., can solve problems such as large short-circuit current, reduce power supply reliability, and reduce service life, and achieve the effect of avoiding impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

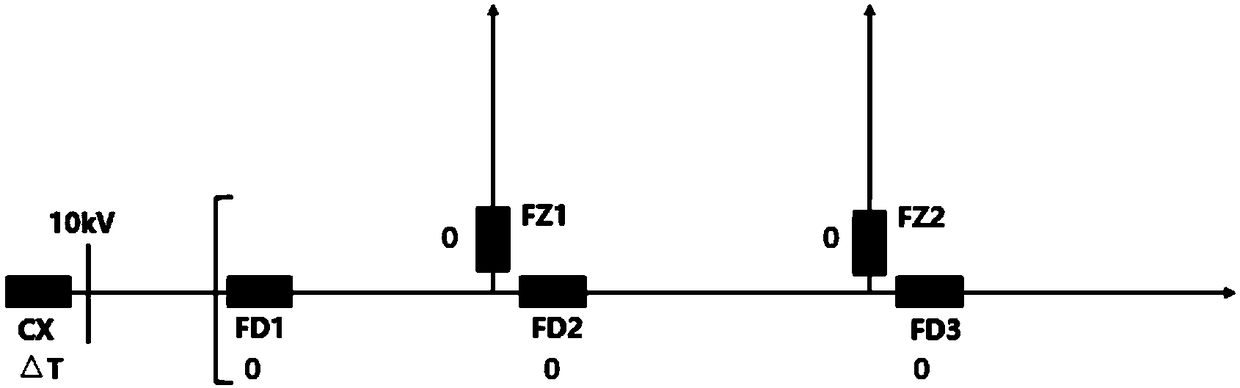

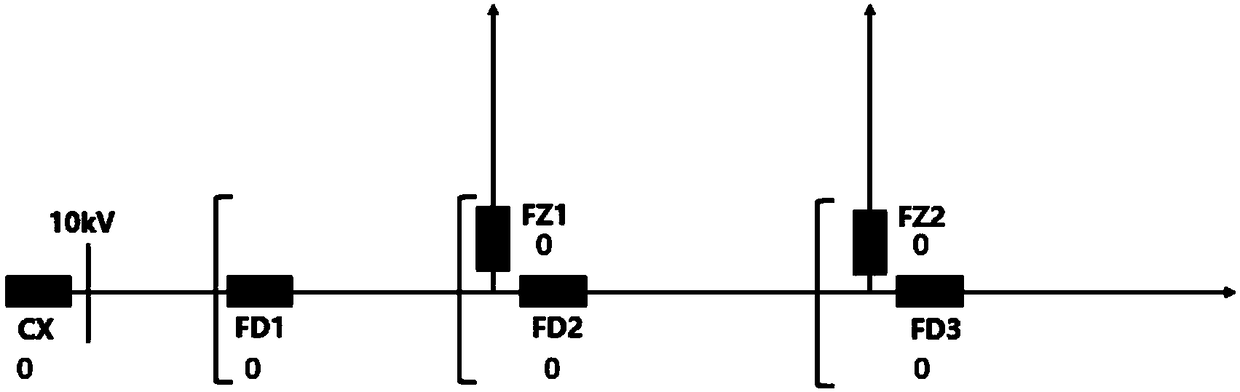

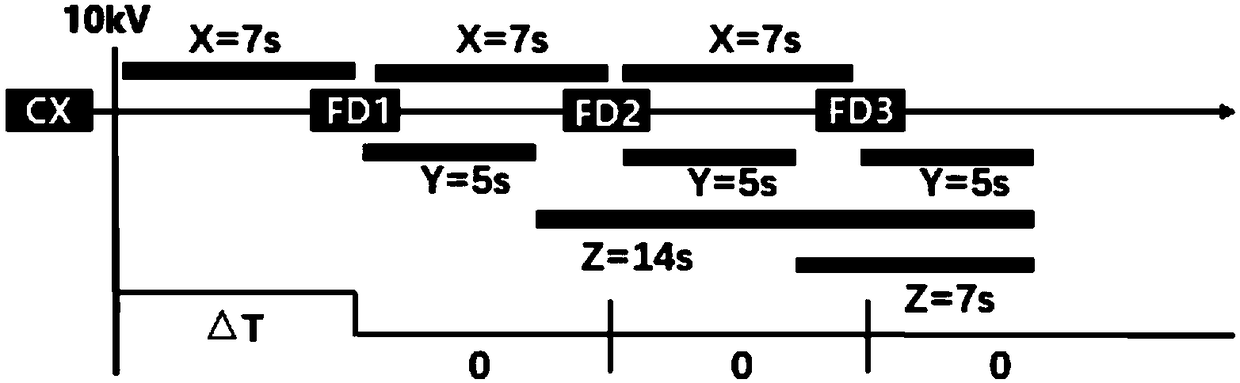

[0044] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0045] The on-site intelligent feeder automation without delay level difference coordination method requires that the intelligent terminals of the distribution line all use circuit breakers, with three-stage overcurrent protection functions, closing when there is pressure delay, reclosing at fault locking, short-time opening and locking, Delayed automatic unlocking function, and also has ground fault judgment and protection functions.

[0046] Since the non-delay step-difference coordination method is suitable for substations with small delay margin or no delay margin, it is suitable for the coordina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com