Tooth socket for invisible dental orthodontics and set for dental orthodontics

A technology of invisible orthodontics and braces, applied in the field of orthodontics, can solve problems such as insufficient force on braces, and achieve precise expression and good orthodontic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

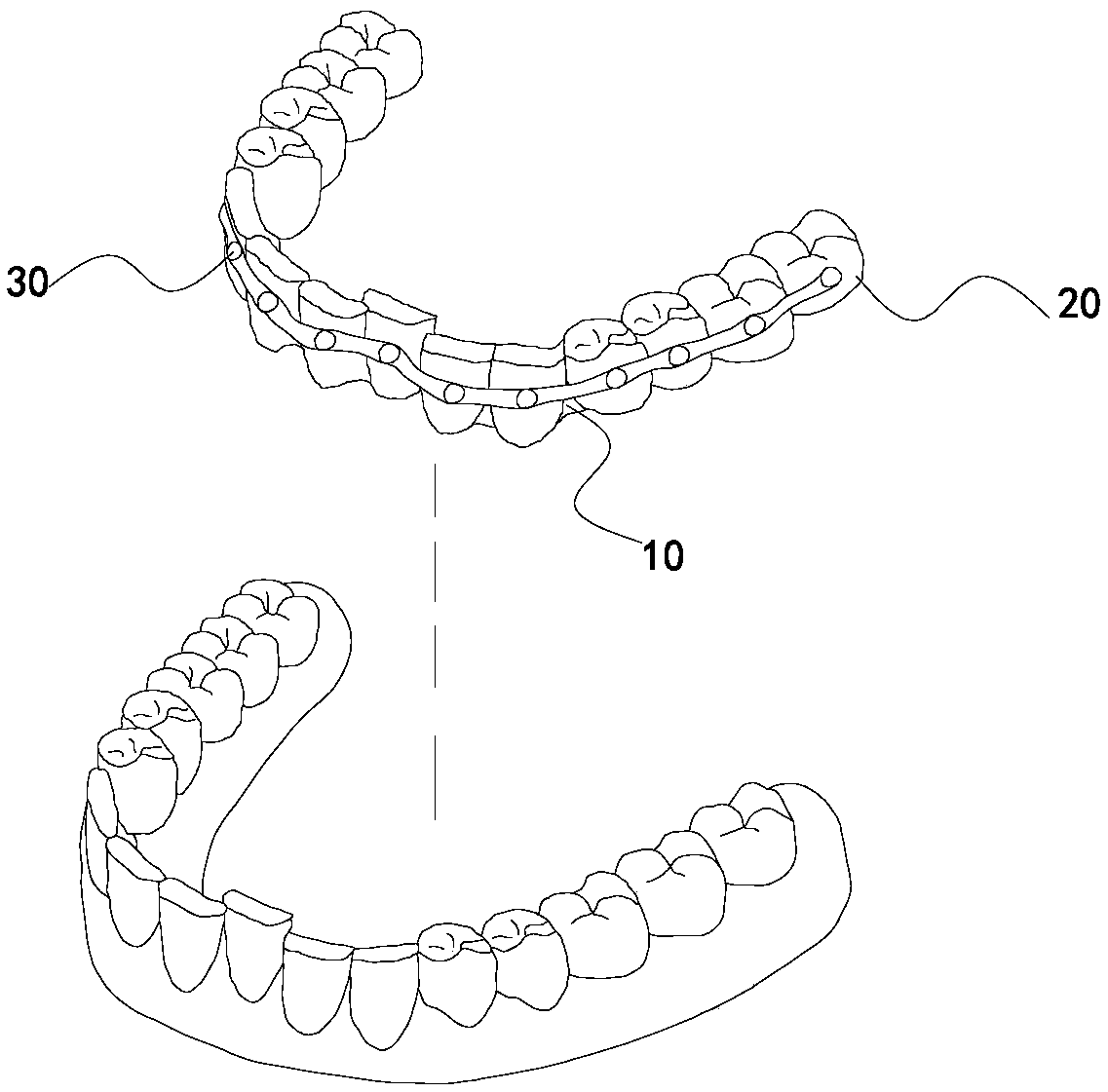

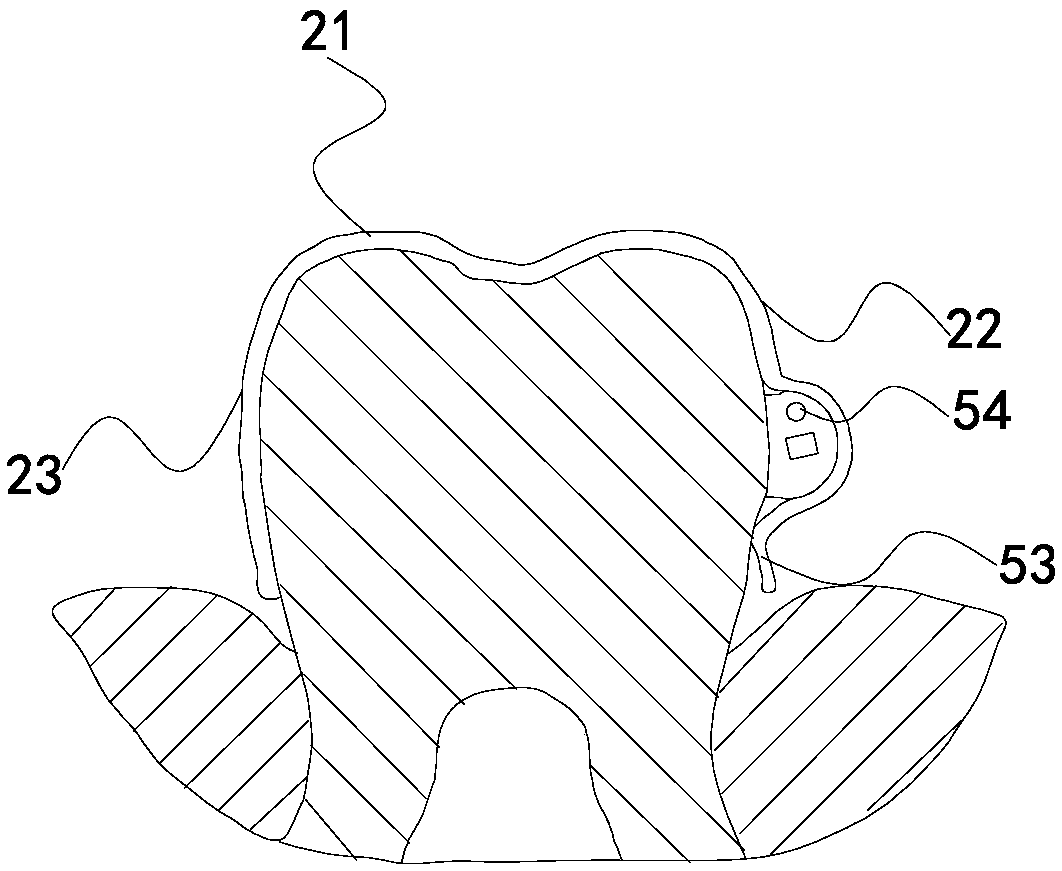

[0043] This embodiment discloses a set for orthodontics, including a braces for invisible orthodontics and an accessory mechanism, and the braces for invisible orthodontics include a braces mechanism, such as figure 1 As mentioned above, the mouthpiece mechanism of this embodiment includes an upper jaw mouthpiece and a lower jaw mouthpiece 10, the upper jaw mouthpiece cooperates with the upper jaw teeth, the lower jaw mouthpiece 10 cooperates with the lower jaw teeth, the upper jaw mouthpiece and the lower jaw mouthpiece 10 are generally made by 3D printing, and the upper jaw mouthpiece and the mandibular braces 10 are all transparent materials, the upper jaw braces are provided with a plurality of dental crowns 20, and the multiple dental crowns 20 on the upper jaw braces are connected in sequence to form a U-shaped structure, and the lower jaw braces 10 are also provided with multiple dental crowns Cover 20, a plurality of dental crown covers 20 on the mandibular dental cover...

no. 2 example

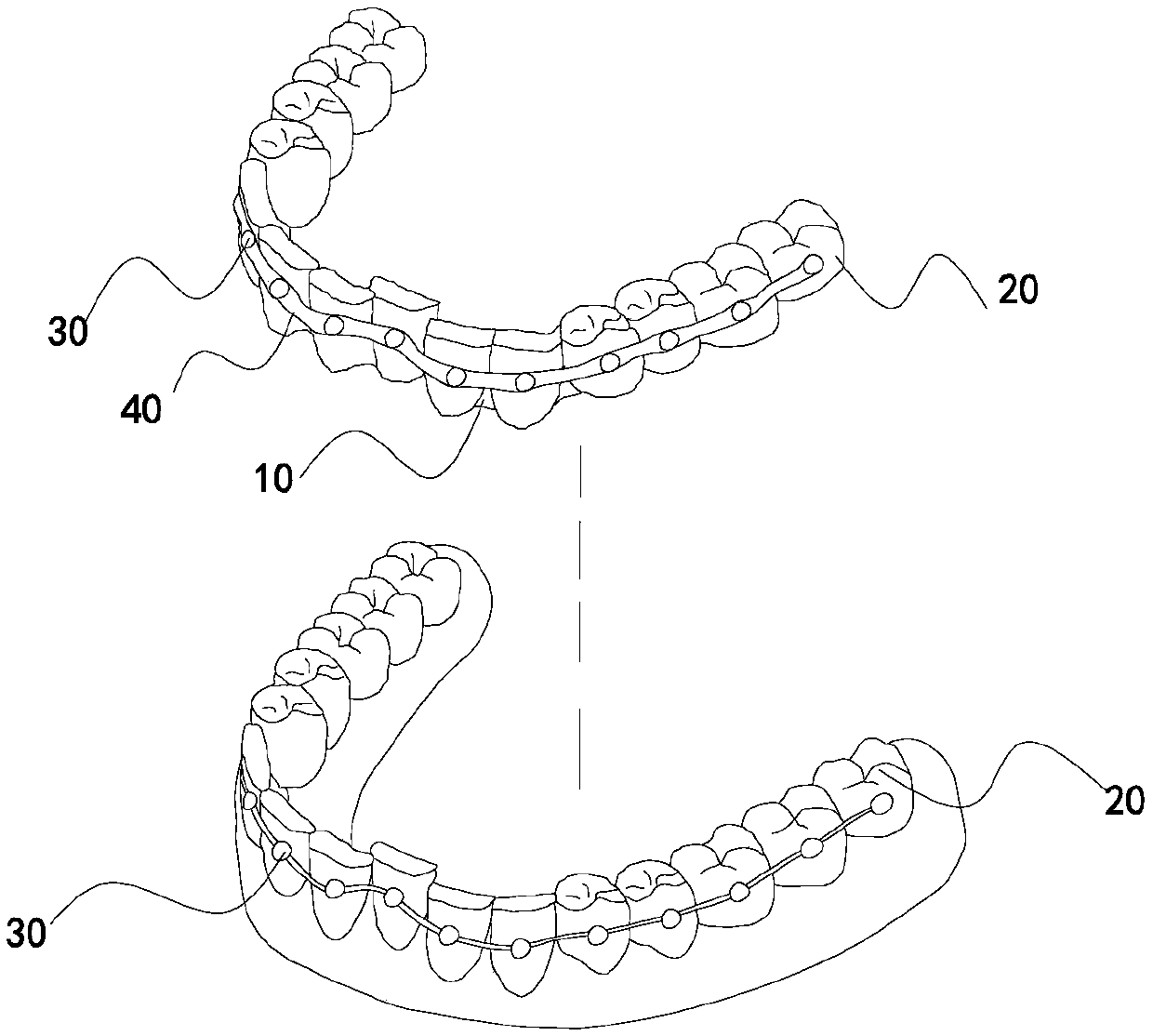

[0083] This embodiment discloses a brace for orthodontics, including an attachment mechanism and a brace for invisible orthodontics, wherein the brace for invisible orthodontics includes a brace mechanism, and the attachment mechanism of this embodiment is the same in structure as that of the first embodiment. The braces mechanism of the embodiment is different from the structure of the first embodiment. The braces mechanism of the present embodiment includes the maxillary braces and the mandibular braces 10, the maxillary braces cooperate with the upper jaw teeth, the lower jaw braces 10 cooperate with the lower jaw teeth, the upper jaw braces and the mandibular braces 10 is generally made by 3D printing, and the upper jaw and the lower jaw 10 are made of transparent materials, and the upper jaw is provided with a plurality of crowns 20, and the plurality of crowns 20 on the upper jaw are connected in sequence to form a U-shaped structure. The mandibular brace 10 is also provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com