Energy-saving type index-adjustable direct flotation system for iron ore concentrate products

A mineral product, positive flotation technology, applied in the field of positive flotation system, can solve the problems of increasing the dosage of chemicals, small room for adjustment, reducing the flotation effect, etc., to reduce the time of natural cooling, avoid energy waste, and ensure flotation. select effect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

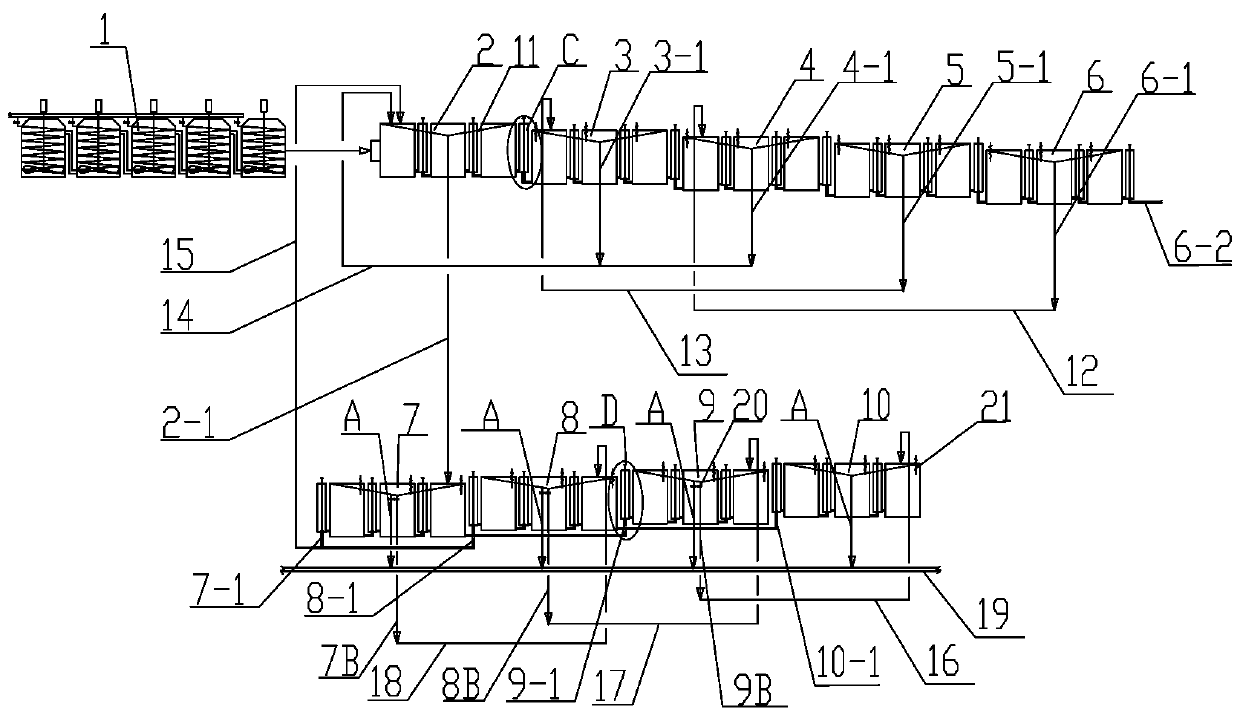

[0026] like figure 1 Shown, a kind of multi-product positive flotation system of the present invention comprises flotation reagent stirring system 1, rough flotation operation system, sweep flotation operation system and fine flotation operation system, it is characterized in that:

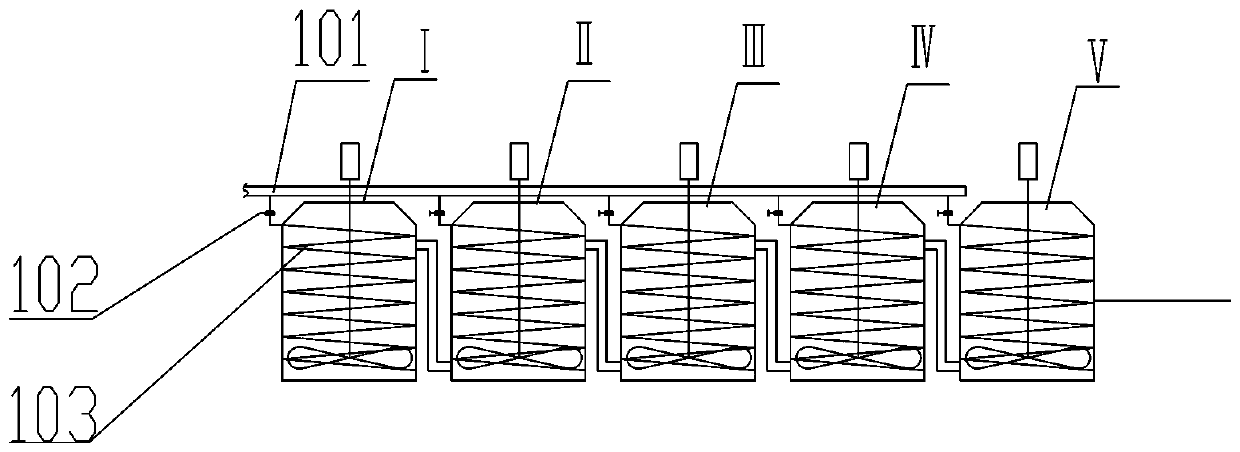

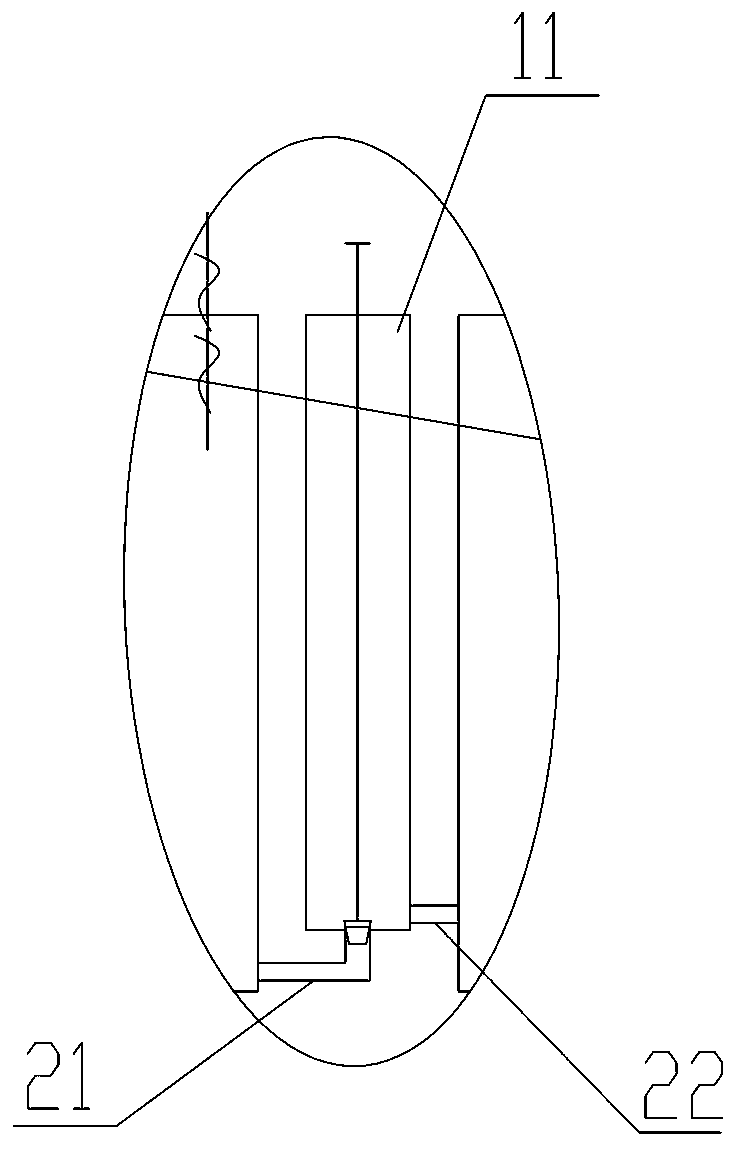

[0027] like figure 2As shown, the flotation agent stirring system 1 of the present invention adopts five flotation agent stirring tanks connected in sequence, the first pH regulator stirring tank, the second dispersant stirring tank, and the third useful mineral stirring tank. The activator stirring tank, the fourth gangue mineral inhibitor stirring tank, the fifth useful mineral collector and foaming agent stirring tank, the five stirring tanks are equipped with spiral steam pipes 103 each along the inner tank wall The entrances of the steam pipes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com