Magnetic digital microfluidic chip and loading structure thereof

A digital microfluidic and chip technology, applied in fluid controllers, laboratory equipment, laboratory containers, etc., can solve the problems of inconvenient transfer of liquid droplets, inconvenient separation of magnetic particles and liquid droplets, and poor usability. Good protection and storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

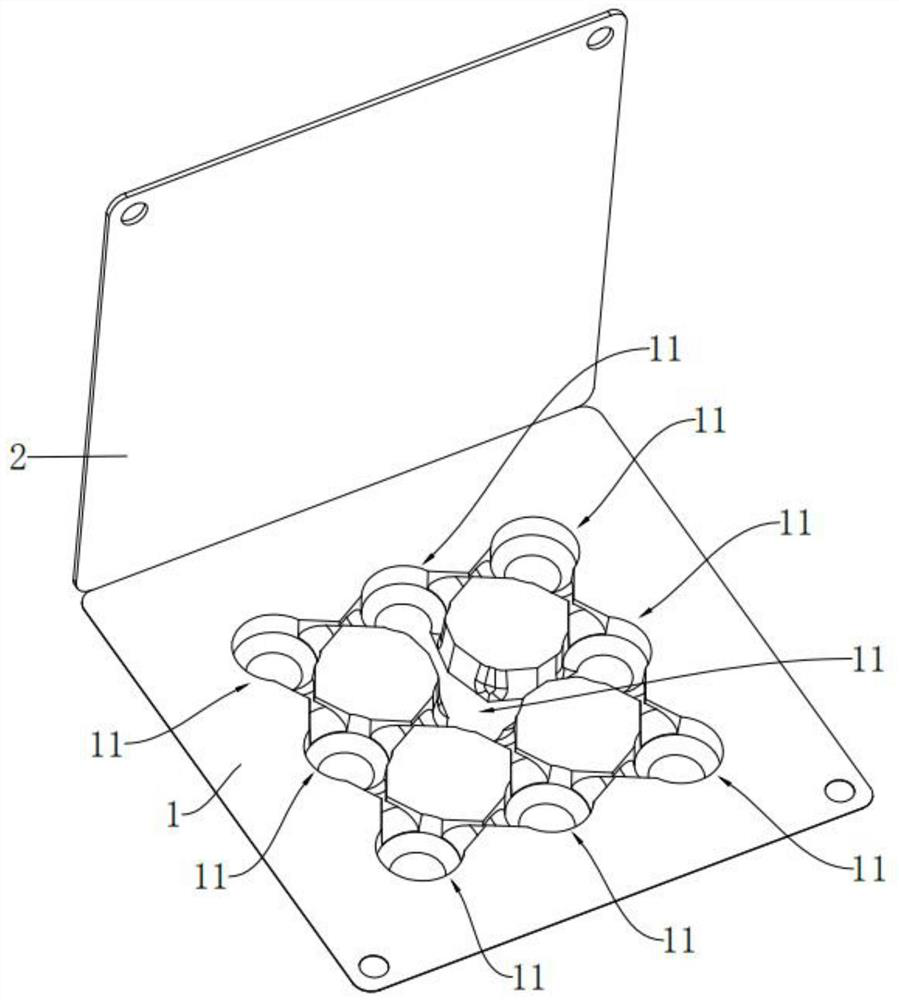

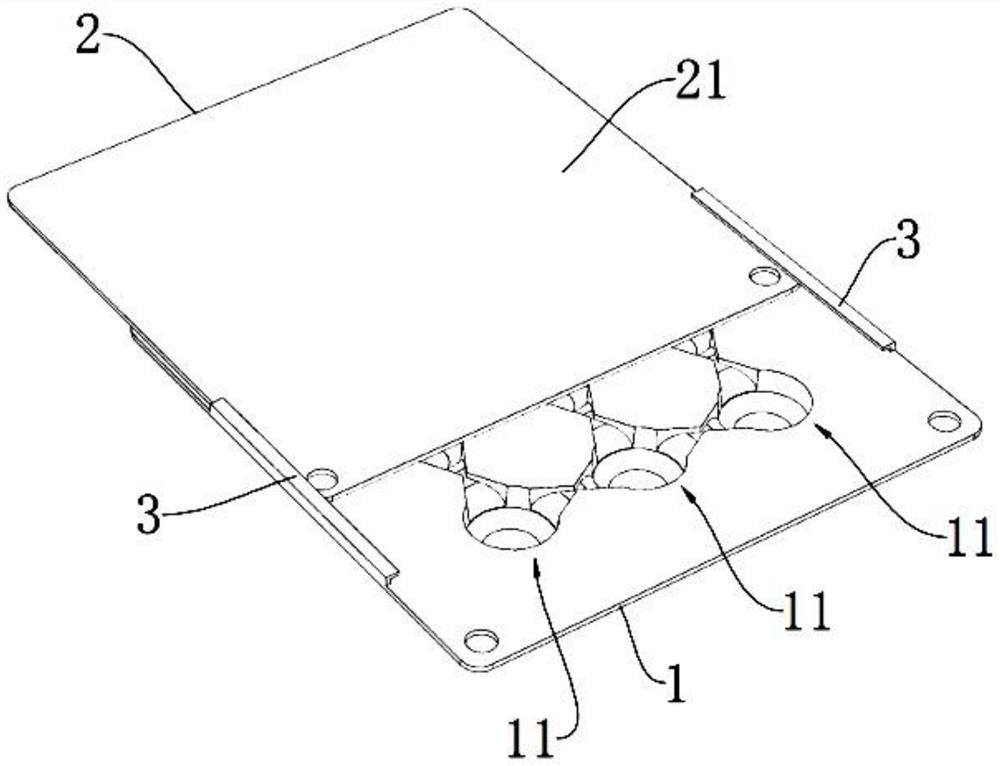

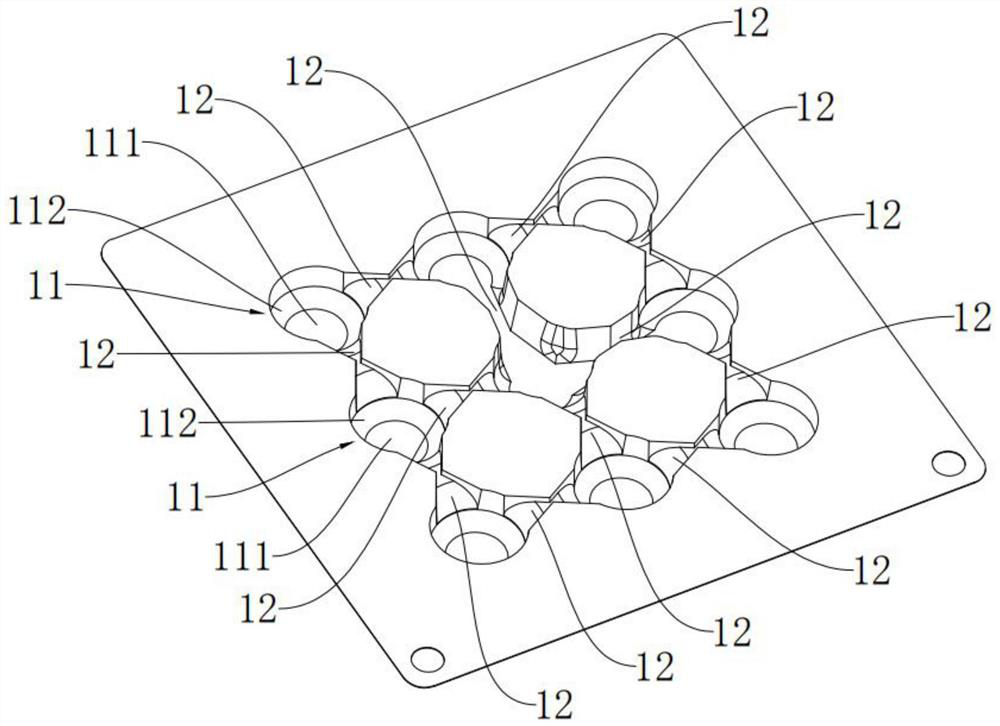

[0034] Such as Figure 1-Figure 3 As shown, the present invention provides a magnetic digital microfluidic chip, which is PVC (polyvinyl chloride), PC (polycarbonate), PP (polypropylene), PET (polyethylene terephthalate), Quartz or metal materials, but the material of this chip is not limited to the above materials, it can be processed by blister technology, injection molding process, computer numerical control machine tool (CNC) processing, hot pressing process, 3D printing, etc., but the chip’s The processing is not limited to the above-mentioned processing methods, and the material is preferably PET (polyethylene terephthalate) in this embodiment.

[0035] Specifically, the magnetic digital microfluidic chip includes a chip base plate 1 and a chip cover plate 2 . Wherein, the end surface of the chip bottom plate 1 facing the chip cover plate 2 is provided with several droplet chambers 11 distributed in a regular or irregular array and opening above. In this embodiment, the...

Embodiment 2

[0041] Such as Figure 4 and Figure 5 As shown, the present invention also provides a magnetic digital microfluidic chip loading structure, which includes the adapter 4 and the magnetic digital microfluidic chip 5 described in the first embodiment.

[0042] Wherein the adapter 4 includes an upper cover plate 41 and a lower cover plate 42, the middle part of the lower cover plate 42 is provided with a chip receiving groove 421 adapted to the shape of the magnetic digital microfluidic chip 5, and the lower cover plate 42 is used to place the magnetic The digital microfluidic chip 5 is fixed in the chip containing groove 421 . For example, one end of the upper cover 41 is hinged to one end of the lower cover 42 to form an openable structure. Specifically, when storing, the magnetic digital microfluidic chip 5 can be placed in the chip receiving groove 421 of the lower cover 42, and then the upper cover 41 and the lower cover 42 can be closed mutually. By using the adapter 4, n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com