Automatic bolt testing machine

A detection machine and automatic technology, applied in sorting and other directions, can solve the problems of easy false detection, low efficiency, and no significant improvement in efficiency, and achieve the effect of low false detection rate, high efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

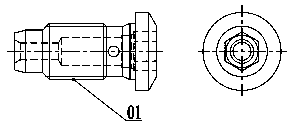

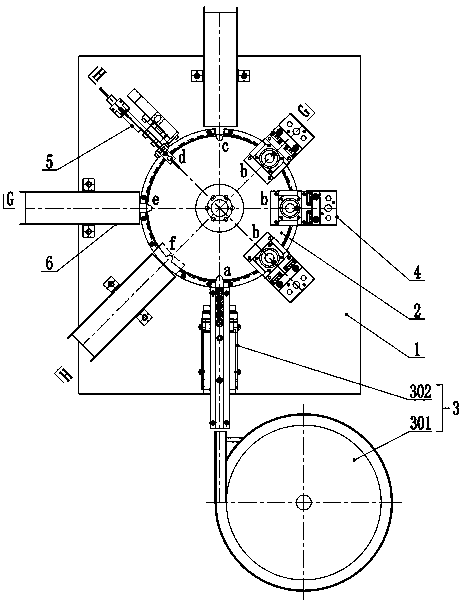

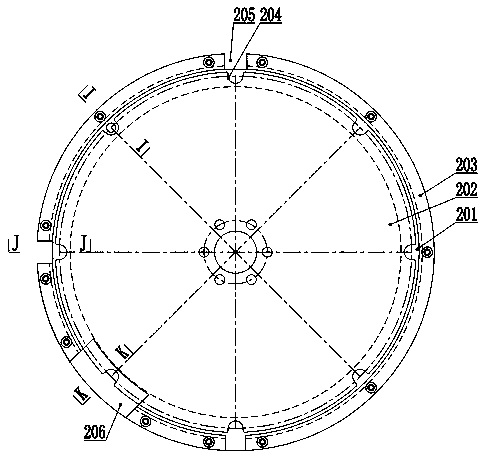

[0035] In the example, such as figure 2 As shown, a bolt automatic detection machine includes: a frame 1, and the frame 1 is provided with a feed station a, a height detection station b, a height unqualified product exit station c, and a thread detection station along the circumference d, thread unqualified product export station e, qualified product export station f; turntable table 2, which performs intermittent rotation, is installed in the center of each station of the frame 1, and its circumferential direction corresponds to each station. Several feeding gaps; the feeding mechanism 3 is used to transport the workpiece 01 to be inspected from the silo to the feeding station a; the height detection mechanism 4 is set at the height detection station b to detect the length of the workpiece 01 to be inspected ; The thread detection mechanism 5 has a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com